Five-element FeCoNiMoSi series high-entropy alloy and preparing method thereof

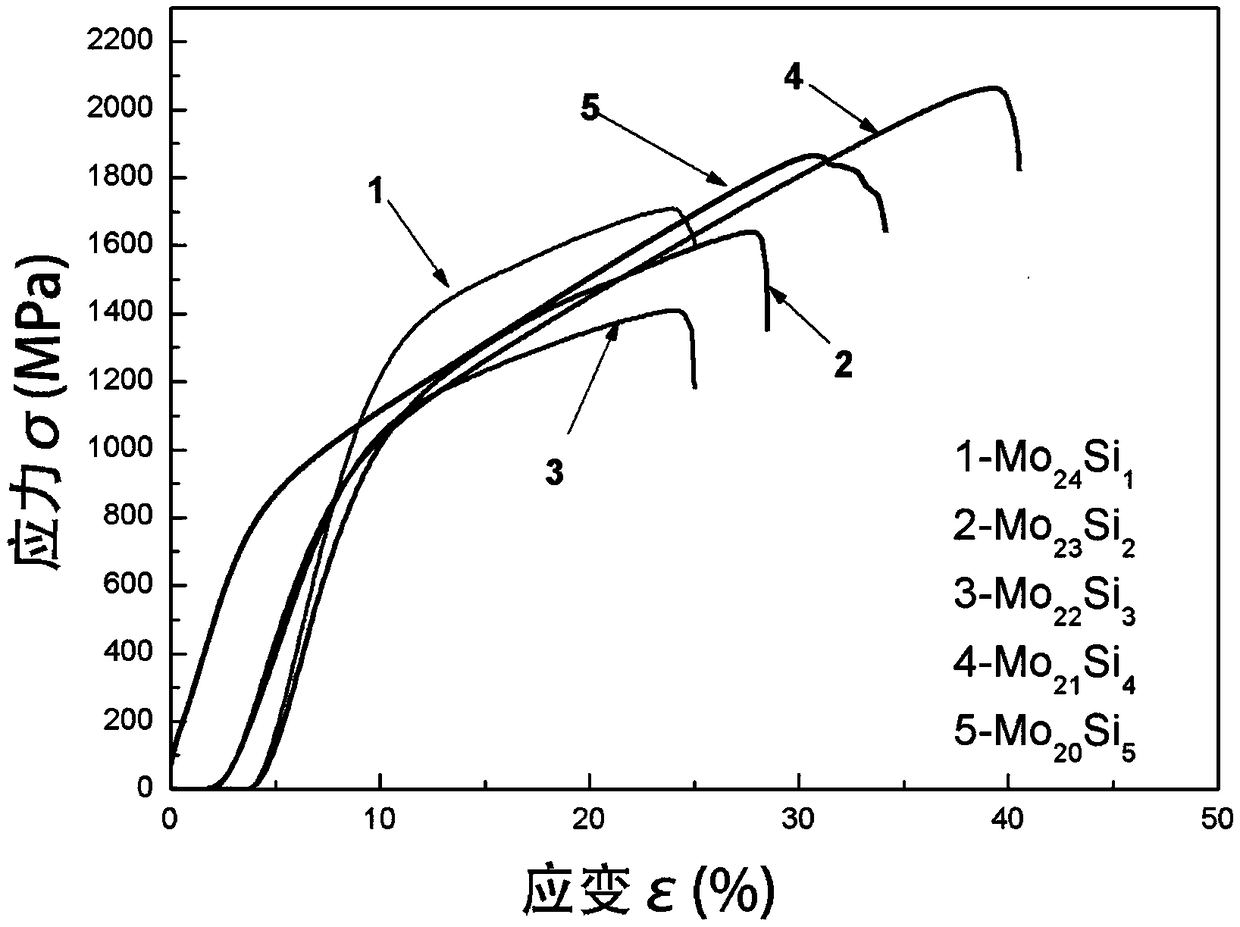

A technology of high-entropy alloys and alloys, applied in the field of FeCoNiMoSi high-entropy alloy materials and their preparation, can solve the problems of alloy plasticity reduction and achieve the effect of excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation process of embodiment 1 high entropy alloy is as follows:

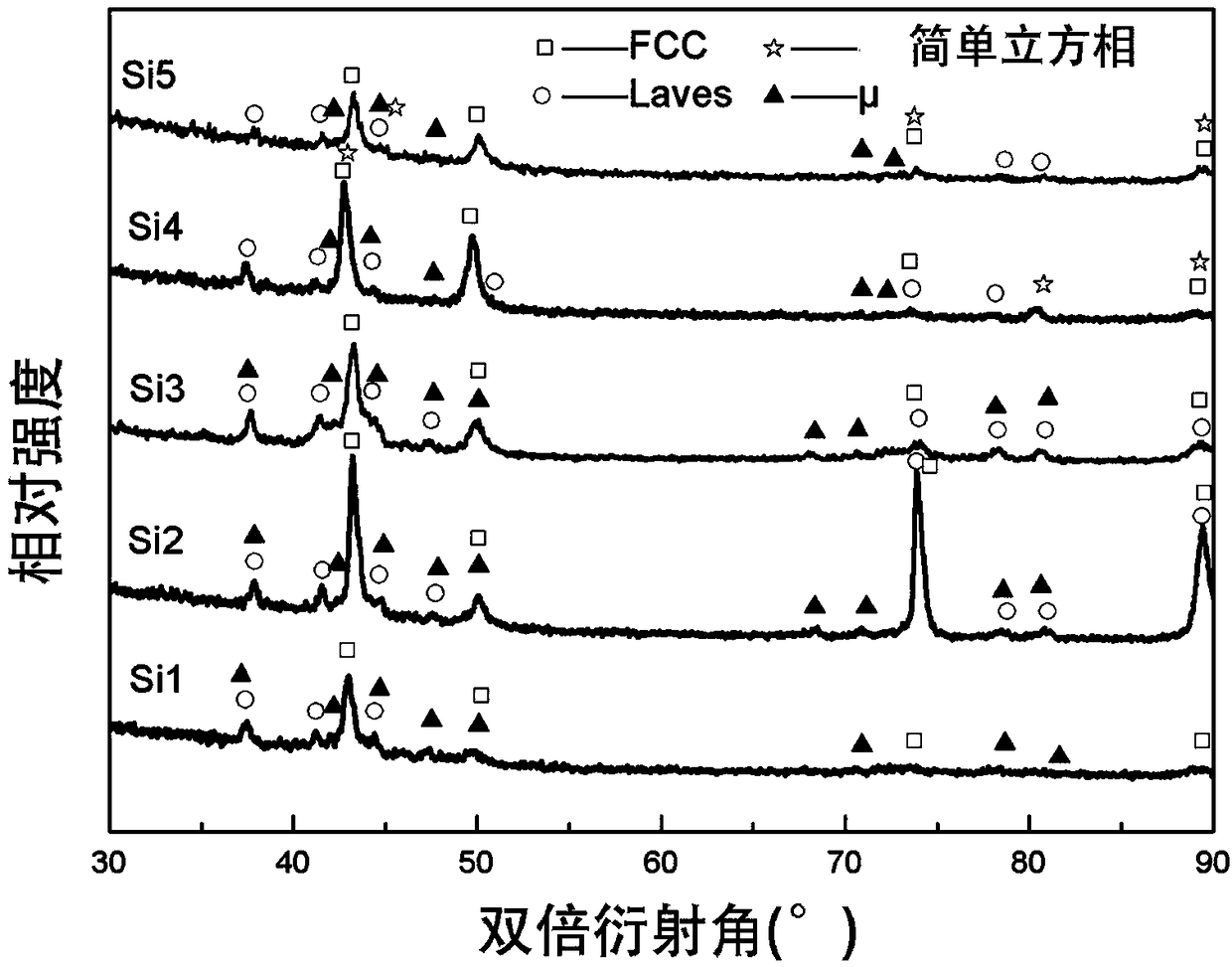

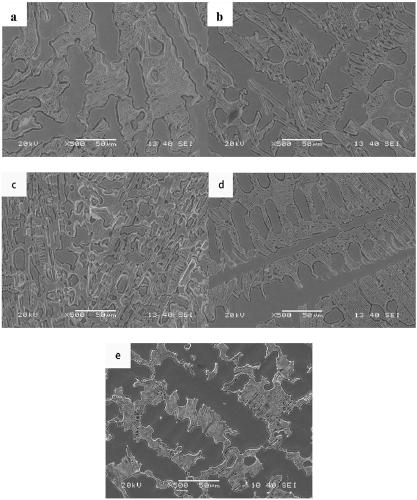

[0022] 1) Raw material preparation: the mass percentage is converted according to the atomic percentage, and the high-purity metal raw material (≥99.95%) is accurately weighed and proportioned according to the mass percentage for use in smelting alloys. The alloy composition is shown in Table 1, according to x=1, 2, 3, 4, 5, represented by Si1, Si2, Si3, Si4 and Si5 respectively.

[0023] Table 1. (FeCoNi) 75 Mo 25-x Si x (x = 1, 2, 3, 4, 5) Nominal composition (at%) of the high-entropy alloy.

[0024]

[0025] 2) Melting of high-entropy alloys: In this embodiment, a WK type non-consumable vacuum electric arc furnace is used, and the weighed elemental raw materials are put into the water-cooled copper mold melting pool in the vacuum electric arc furnace, oxygen-absorbing titanium is placed in the middle of the crucible, and then Close the oven door and tighten the knob. Then vacuumize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com