Preparation method of antibacterial durable stable viscose fiber material

A viscose fiber and stable technology, which is applied in the field of preparation of antibacterial durable and stable viscose fiber materials, can solve the problems of low antibacterial durability and achieve the effects of improving inclusion performance, excellent spinning performance, and good health care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

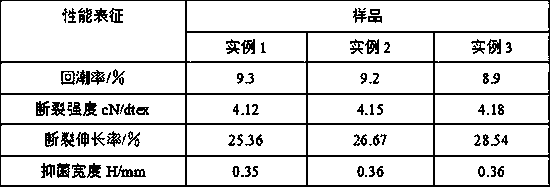

Examples

example 1

[0017] Take tea tree branches and cut them to 3cm to get crushed branches. Add the crushed branches to deionized water at a mass ratio of 1:10, stir and mix and shake for 25 minutes. Collect the mixed solution and heat it in an oil bath at 125°C. After heat preservation treatment for 3 hours, after standing still for 6 hours, collect the upper oil phase to obtain the matrix tea tree oil, add the matrix tea tree oil to the cholesterol at a mass ratio of 5:1, stir and mix, and heat up at 45°C for 1 hour to obtain a modified Add the modified mixed solution to absolute ethanol at a volume ratio of 1:5, stir and mix to obtain a diluted solution, and add a mass fraction of 5% cyclodextrin aqueous solution to the diluted solution dropwise at a volume ratio of 1:8 In the process, the dropping rate was controlled at 3mL / min. After the dropwise addition was completed, it was stirred and mixed at 45°C for 3 hours, left to cool to room temperature, filtered with a 0.45 micron filter membra...

example 2

[0019] Take the tea tree branch and cut it to 4cm to get the crushed branch. Add the crushed branch to deionized water according to the mass ratio of 1:10, stir and mix and vibrate for 27 minutes. Collect the mixed solution and heat it in an oil bath at 127°C. After heat preservation treatment for 4 hours, after standing still for 7 hours, the upper oil phase was collected to obtain the base tea tree oil. The base tea tree oil was added to the cholesterol at a mass ratio of 5:1, stirred and mixed, and heated at 42°C for 2 hours. Add the modified mixed solution to absolute ethanol at a volume ratio of 1:5, stir and mix to obtain a diluted solution, and add a mass fraction of 5% cyclodextrin aqueous solution to the diluted solution dropwise at a volume ratio of 1:8 In the process, the dropping rate was controlled at 4mL / min. After the dropwise addition was completed, it was stirred and mixed at 47°C for 4h, left to cool down to room temperature, filtered with a 0.45 micron filter...

example 3

[0021] Take tea tree branches and cut them to 5cm to get crushed branches. Add the crushed branches to deionized water at a mass ratio of 1:10, stir and shake for 30 minutes, collect the mixed solution and heat it in an oil bath at 130°C. After heat preservation treatment for 5 hours, after standing still for 8 hours, collect the upper oil phase to obtain the base tea tree oil, add the base tea tree oil to the cholesterol according to the mass ratio of 5:1, stir and mix, heat up at 50°C for 2 hours, and obtain the modified Add the modified mixed solution to absolute ethanol at a volume ratio of 1:5, stir and mix to obtain a diluted solution, and add a mass fraction of 5% cyclodextrin aqueous solution to the diluted solution dropwise at a volume ratio of 1:8 In the process, the dropping rate was controlled at 5mL / min. After the dropwise addition was completed, it was stirred and mixed at 50°C for 5 hours, left to cool down to room temperature, filtered with a 0.45 micron filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com