High-speed effluent navigation body ventilation vacuole multiphase flow characteristic measurement experiment device and method

An experimental device and a technology for an air vehicle, which is applied in the field of an experimental device for measuring the multiphase flow characteristics of aeration and cavitation in a high-speed water-exiting air vehicle, can solve the problems of poor controllability and safety, repeated analog experiments, and inability to observe the fusion process of air and cavitation. problem, to achieve the effect of good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

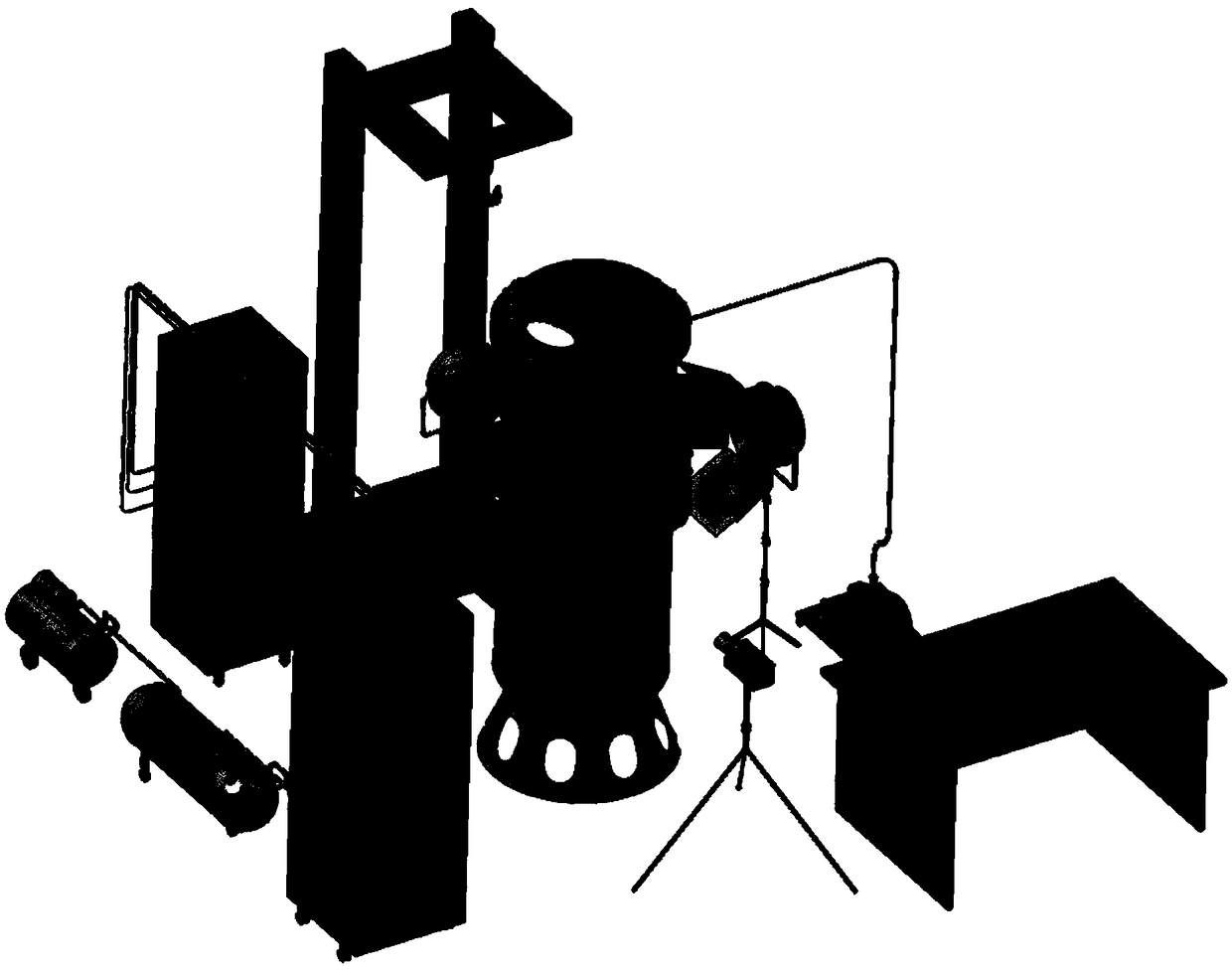

[0032]An experimental device for measuring the characteristics of ventilated cavitation multiphase flow of a high-speed water-exiting vehicle in a decompressed environment, see appendix figure 1 , is characterized in that it is composed of four major parts: a decompression system, a ventilation system, a motion system and a data acquisition system. The decompression tank is placed in the center, and a synchronous belt slide table is placed inside the decompression tank. A yellow headlight is placed 0.5 meters from the right and rear sides of the decompression tank, and a yellow headlight is placed 1 meter from the right side of the decompression tank. Vacuum pump, the vacuum pump is connected to the decompression tube through a transparent air tube, a high-speed camera is placed 1 meter in front of the decompression tank, and a laptop computer connected to it to record data is placed 1 meter to the right of the high-speed camera, and 1.5 meters behind the decompression tank A...

specific Embodiment 2

[0059] 1. An experimental device for measuring ventilation cavitation multiphase flow characteristics of a high-speed water-exiting vehicle in a decompressed environment, characterized in that:

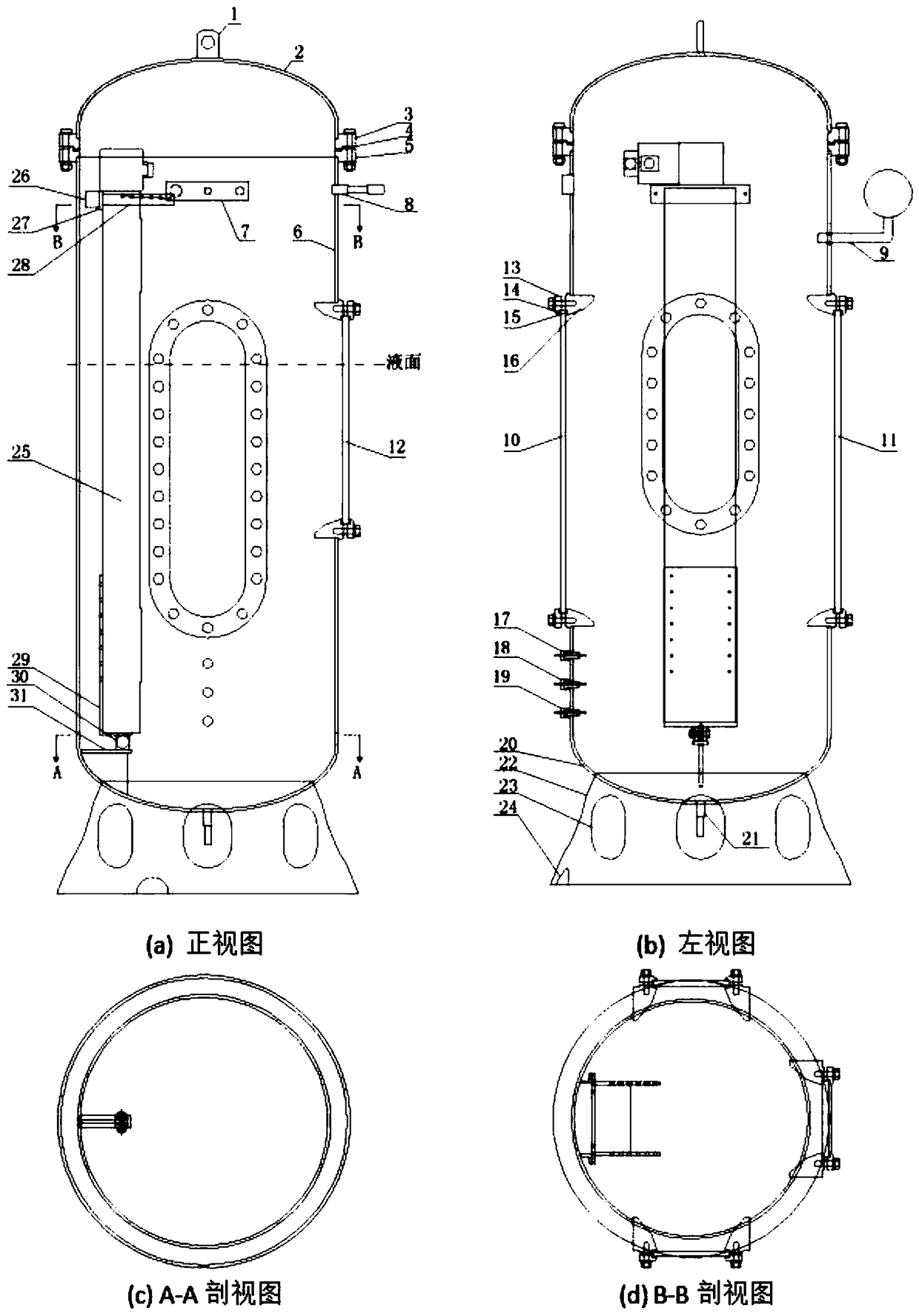

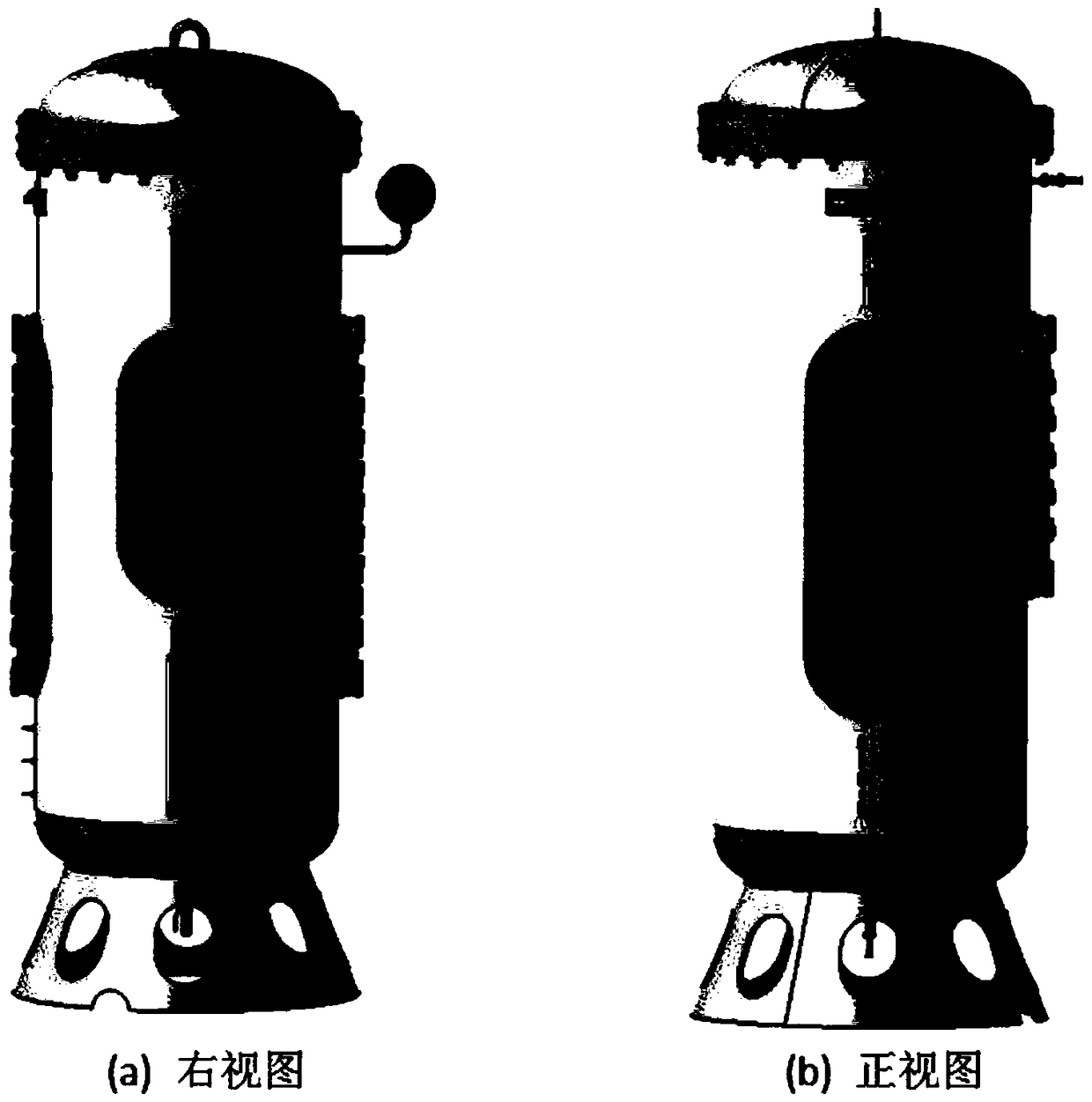

[0060] (1) Decompression tank, if attached figure 2 shown

[0061] The main body of the decompression tank is composed of a top head 2 , a head convex flange 3 , a head concave flange 5 , a cylindrical shell 6 , a bottom head 20 and a conical base 22 from top to bottom.

[0062] There is a lifting ring 1 welded on the outermost top of the elliptical top head 2, and the lower end is welded together with the head convex flange 3, and there is an O-ring 4 between the head convex flange 3 and the head concave flange 5, And through the connection of bolts and nuts, the concave flange 5 of the head and the cylindrical shell 6 are welded together to ensure the tightness and detachability of the decompression tank.

[0063] The upper part of the cylindrical shell 6 is provided with a sucti...

specific Embodiment 3

[0097] The invention provides an experimental device for measuring the multiphase flow characteristics of ventilated cavitation of a high-speed water-exiting vehicle in a decompressed environment. The functions of each experimental system are as follows: Figure 8 shown.

[0098] The method of determining the material and size of the decompression tank is: use the Blake criterion combined with numerical simulation to obtain the influence range of the boundary on the ventilation cavity, thereby determining the size of the decompression tank, and finally use the relevant theories of structural mechanics combined with numerical simulation. method, and referring to the GB150 national standard for fixed pressure tanks, the thickness of the decompression tank body and the sight glass was obtained.

[0099] The way to achieve good air tightness of the decompression tank is: use 24 bolts for a week to fasten between the concave and convex flanges of the top head, and an O-ring groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com