Object-oriented non-condensable gas-containing vapor condensation visualization experiment device

An object-oriented technology for steam condensation, applied in the direction of measuring devices, material condensation, instruments, etc., can solve the problems of complex system, lack of heating device on the wall of the experimental chamber, unsuitable for low-pressure condensation, etc., achieve system simplification, high control accuracy, Experiment with a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

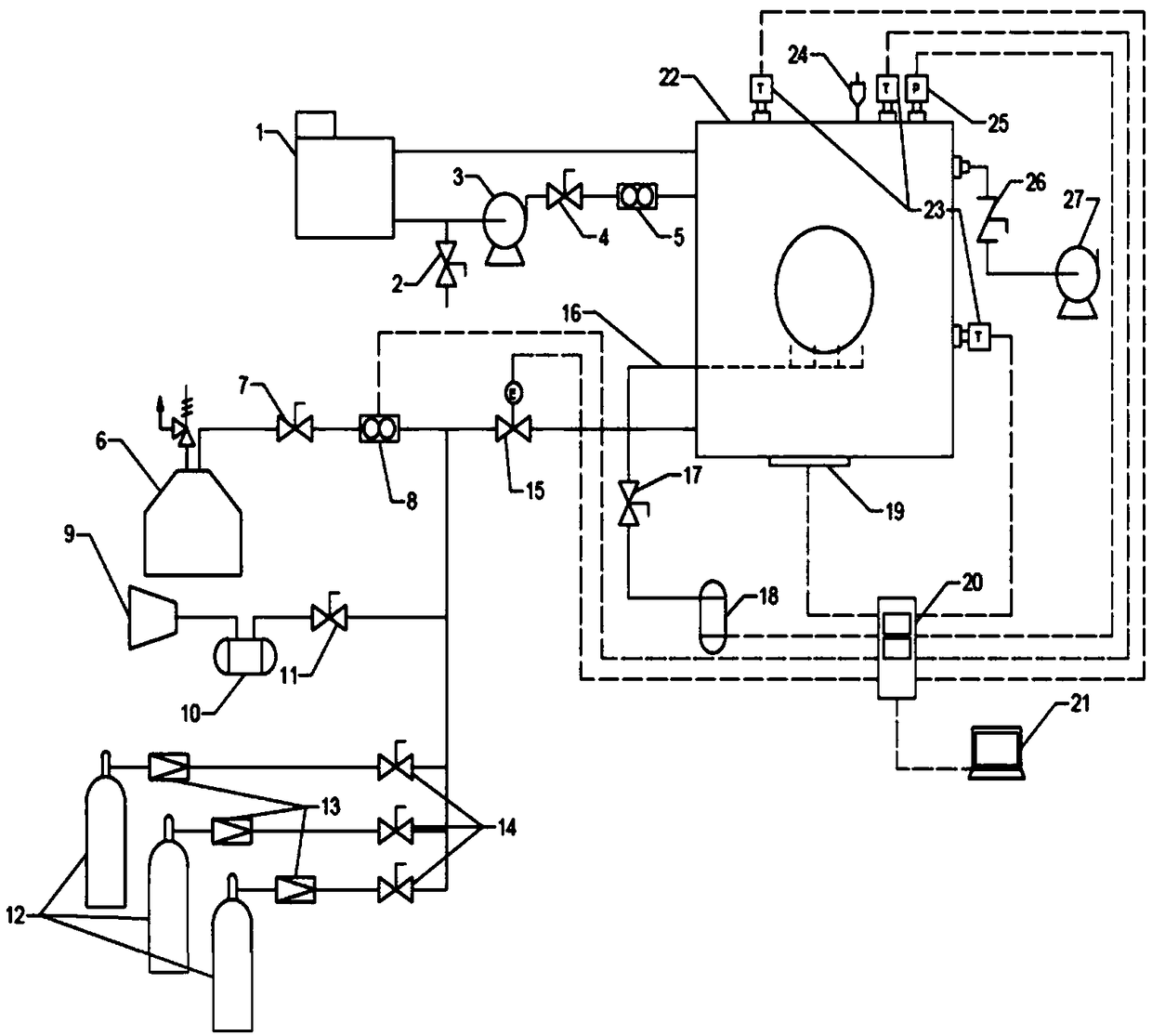

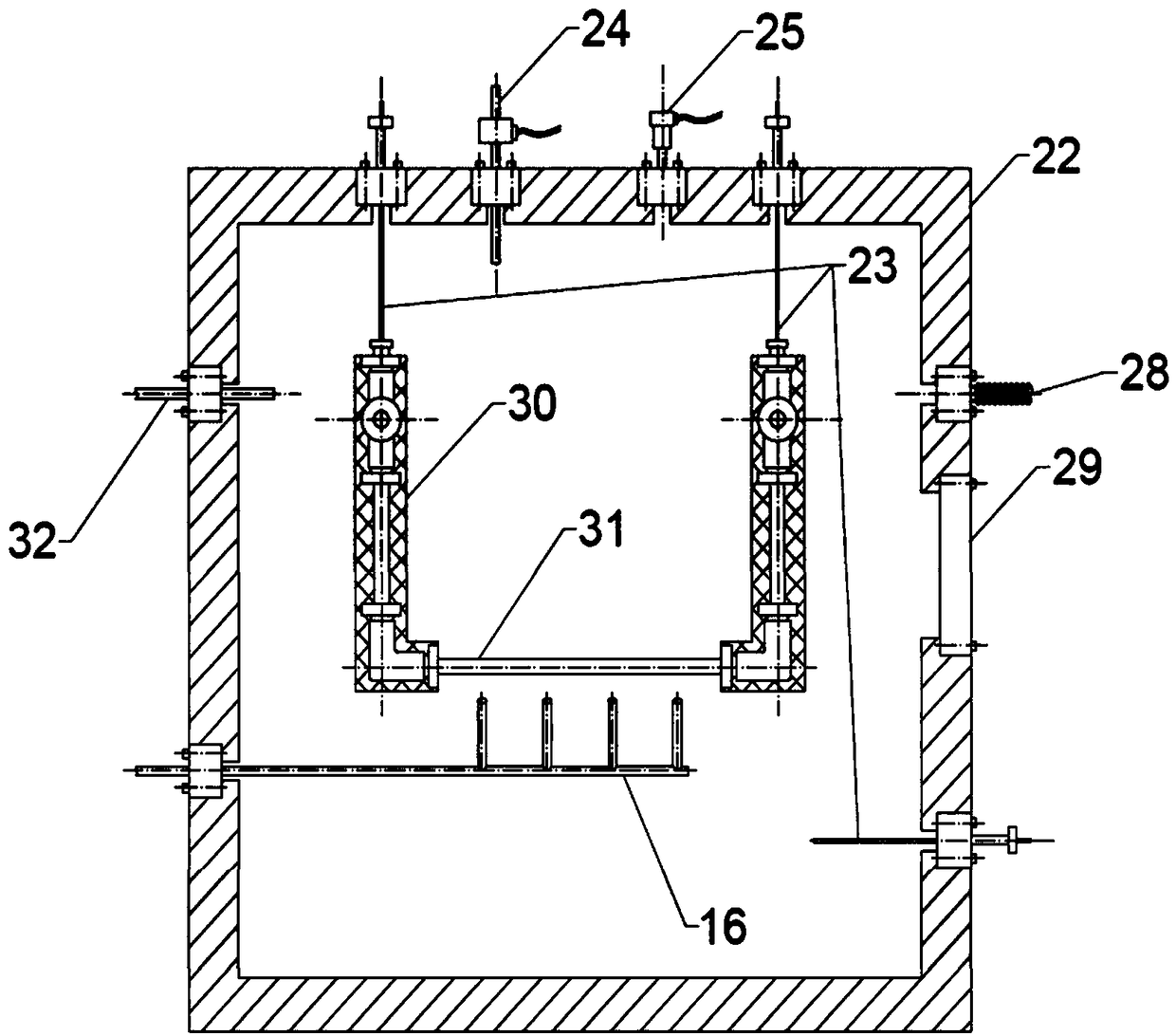

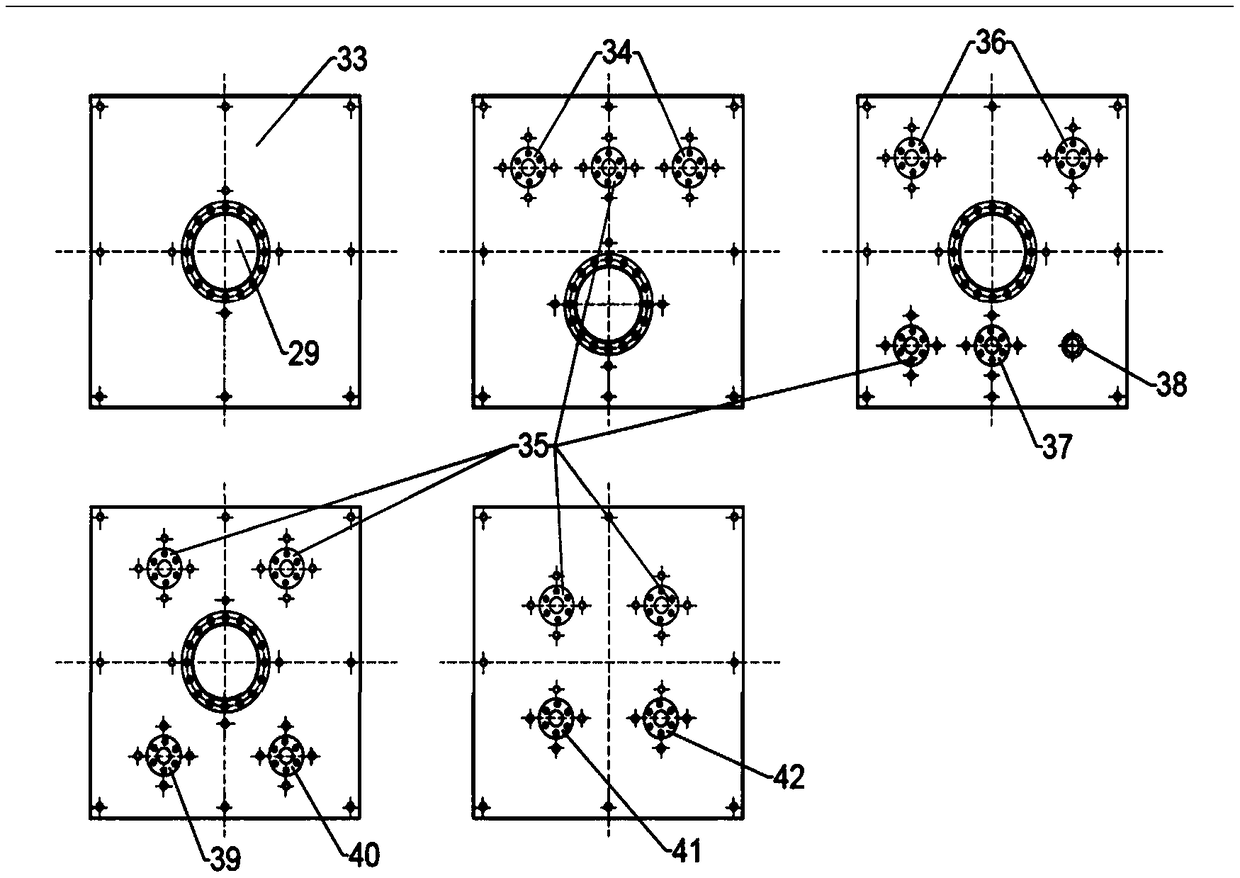

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] It mainly includes steam supply system, air supply system, other gas supply system, cooling water system, visual experiment body and data acquisition system.

[0028] In the steam supply system, the steam generator 6 generates steam, the initial steam flow is controlled by the steam flow regulating valve 7, and the vortex flowmeter 8 records the cumulative flow and the instantaneous flow.

[0029] The air supply system is composed of an air compressor 9 and an air storage tank 10. After the air is compressed, it enters the air storage tank 10 and enters the main air supply pipeline 32 after reaching the set pressure.

[0030] The other gas supply system consists of a high-pressure gas storage cylinder 12 and a pressure reducing valve 13 , and other gases enter the main gas supply pipeline 32 after being decompressed by the high-pressure gas storage cylinder 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com