A numerical simulation method of bevel gear dual-frequency piecewise cyclic induction heating

A high-frequency induction heating and induction heating technology is applied in the field of heat treatment to achieve good heating effect and improve heating uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

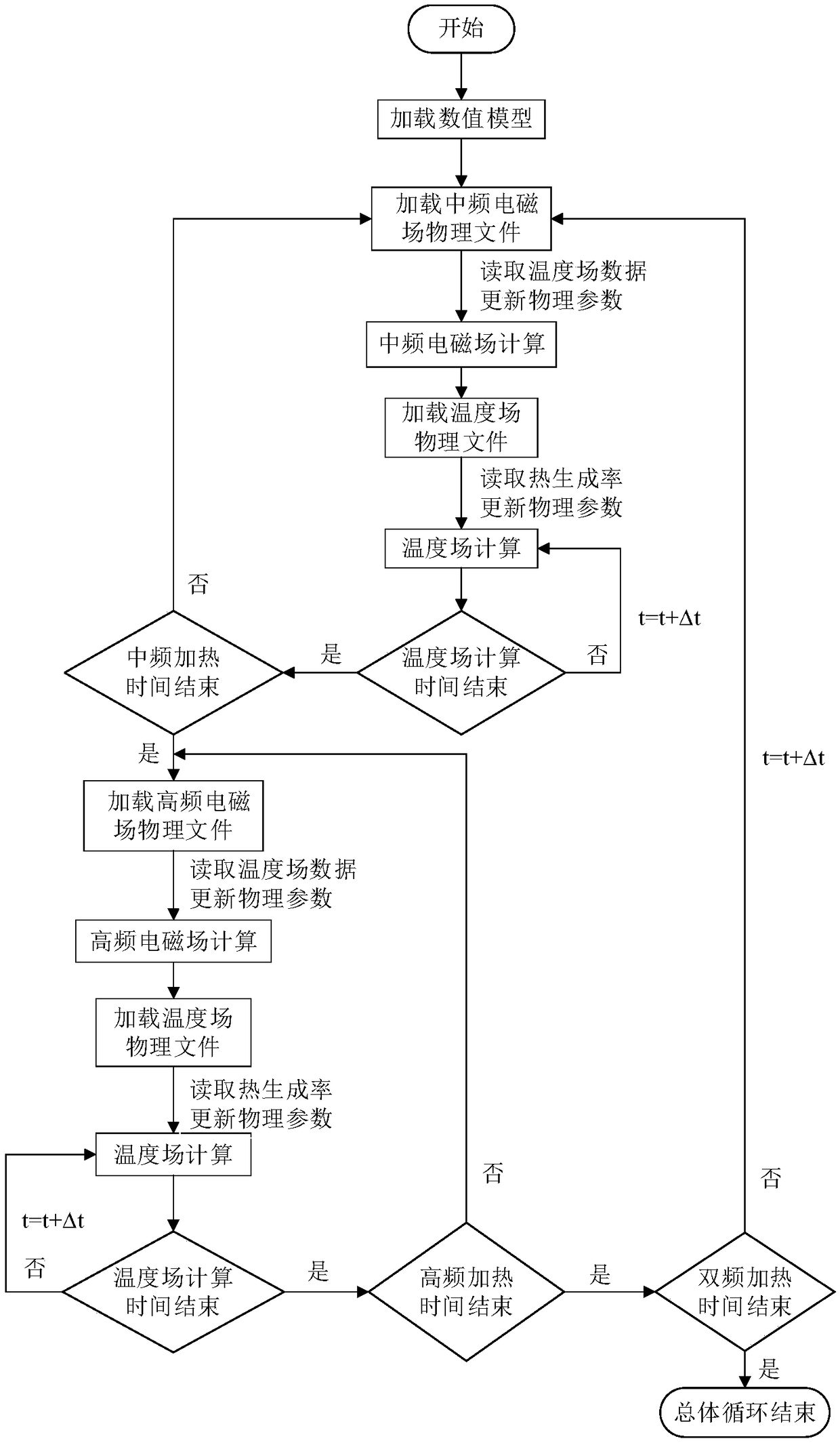

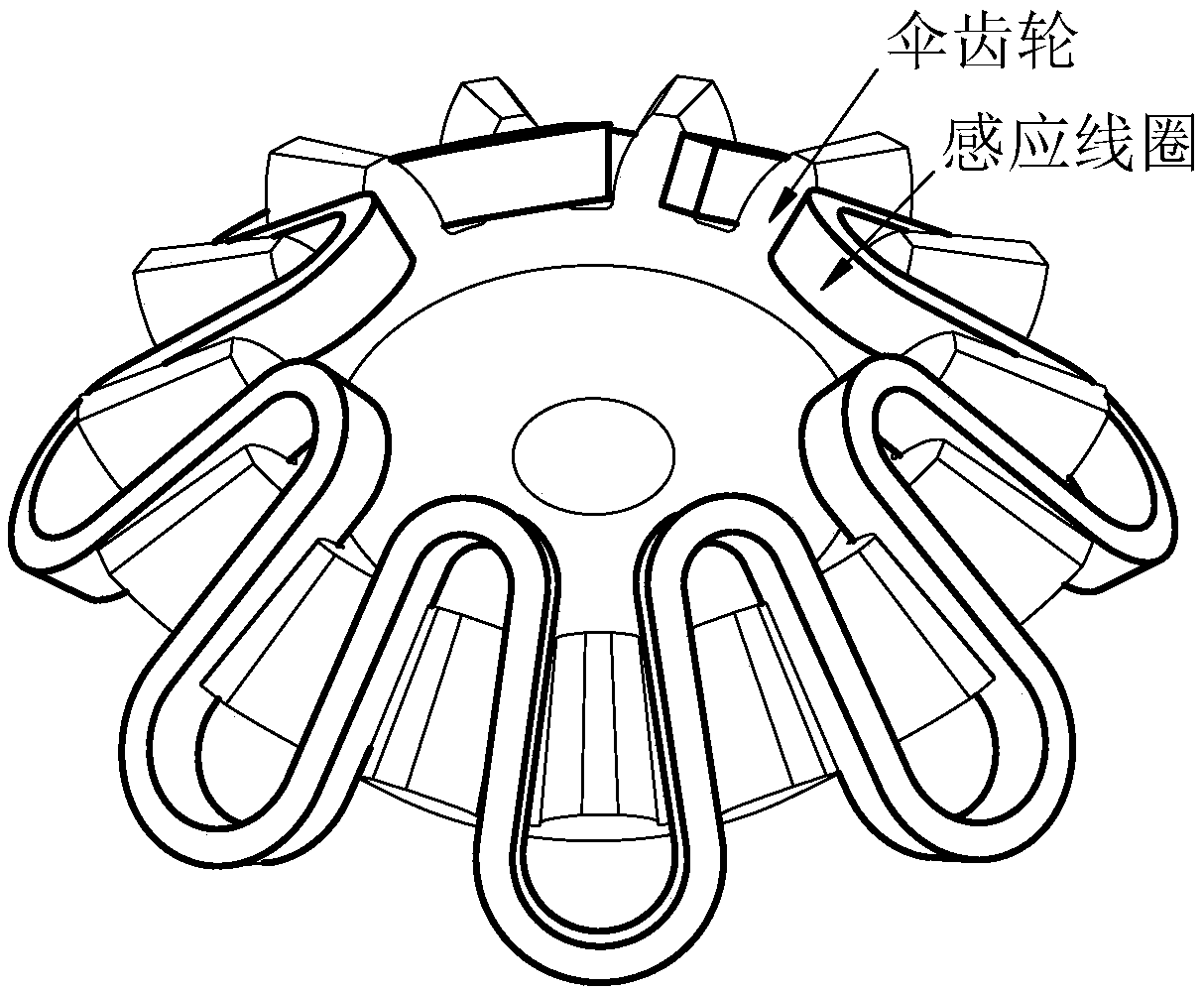

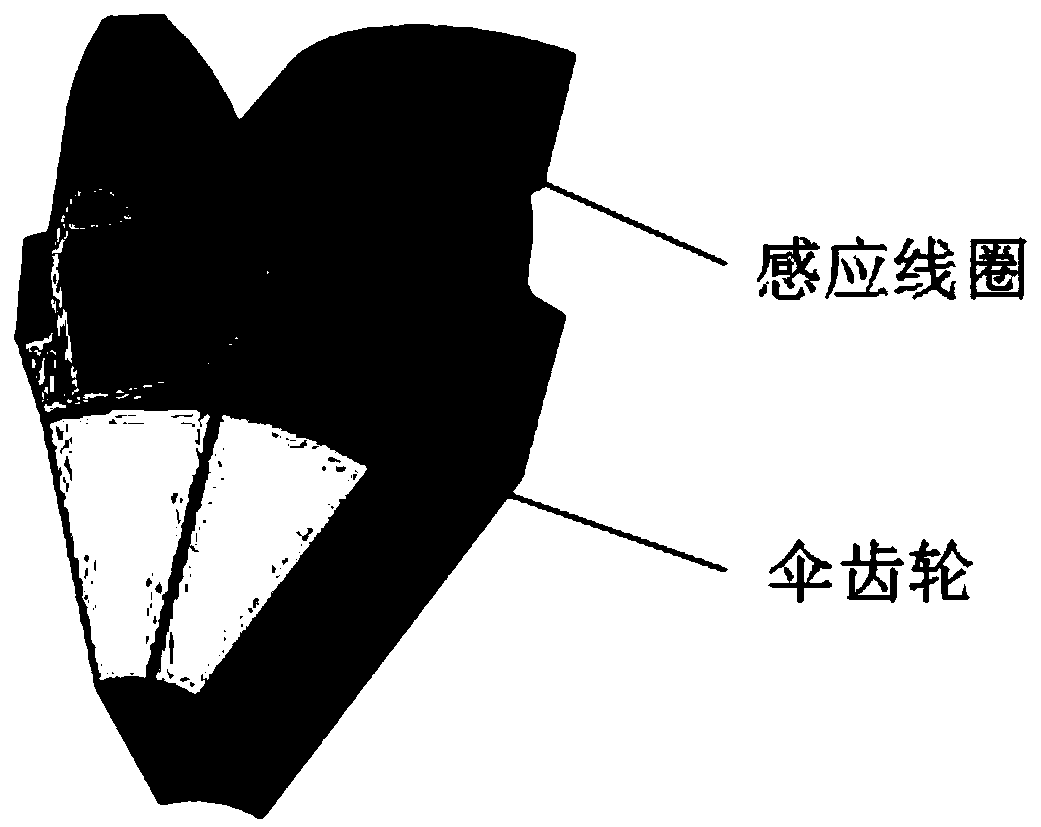

[0024] exist Figure 1 to Figure 4 In the schematic diagram of the present invention shown, the present invention simulates the bevel gear dual-frequency induction heating process, and under the premise of ensuring little influence on the research target, the following assumptions and treatments are made to the simulation process: (1) bevel gear The gear density remains unchanged; (2) In the process of temperature field analysis, the temperature changes of the induction coil and air are not considered: the induction coil is made of copper material, and the resistance is small, so the thermal influence of the resistance is small, and the induction heating time is extremely short. Cooling water is passed into the coil, and the heat change on the coil has little effect on the heating of the workpiece, which can be ignored; (3) When using the "tooth-shaped" induction coil to heat the bevel gear, it is mainly to analyze the effect of dual-frequency induction heating on the gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com