A method of reducing the leakage current of lithium ion capacitor

A technology of capacitors and lithium ions, which is applied in the field of electrochemical energy storage devices, can solve problems such as leakage current, achieve the effects of reducing leakage current, reducing leakage current, and increasing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

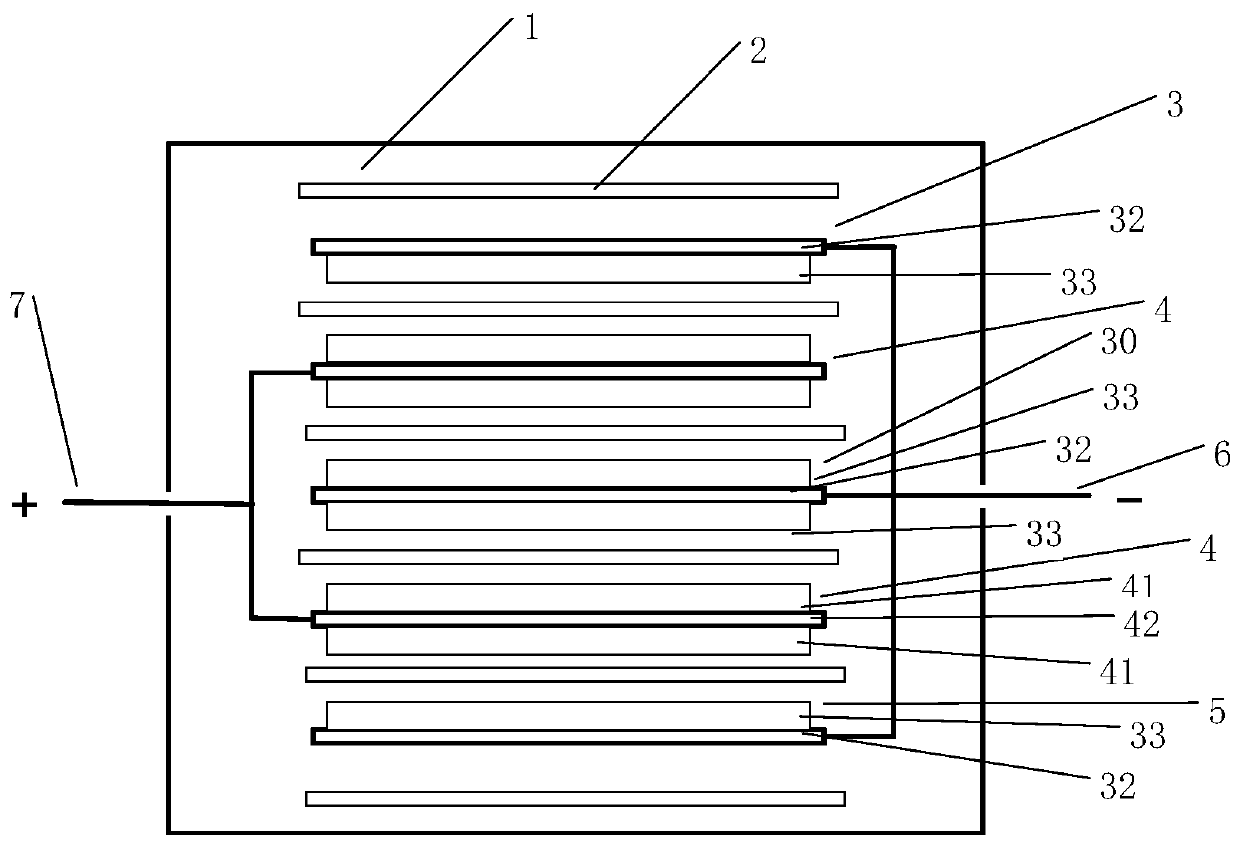

Embodiment 1

[0036] Example 1 Preparation of lithium ion capacitor. The active material is the positive electrode of activated carbon, the active material is the negative electrode of hard carbon, and the electrolyte is 1mol / L LiPF 6 The solution, the solvent is a mixed solvent of ethylene carbonate, dimethyl carbonate and diethyl carbonate with a volume ratio of 1:1:1. Use CT2001A battery tester of Wuhan Landian Company, connect the negative electrode of the cell to the positive electrode of the tester, connect the negative electrode of the tester with the metal lithium electrode, pre-embed lithium on the negative electrode sheet by constant current method, and the amount of pre-embedded lithium is the negative electrode 80% of capacity. After the pre-intercalation of lithium is completed, the metal lithium electrodes are taken out and vacuum-sealed to obtain several lithium-ion battery capacitors. The charge and discharge test was carried out on the lithium ion capacitor in the voltage...

Embodiment 2

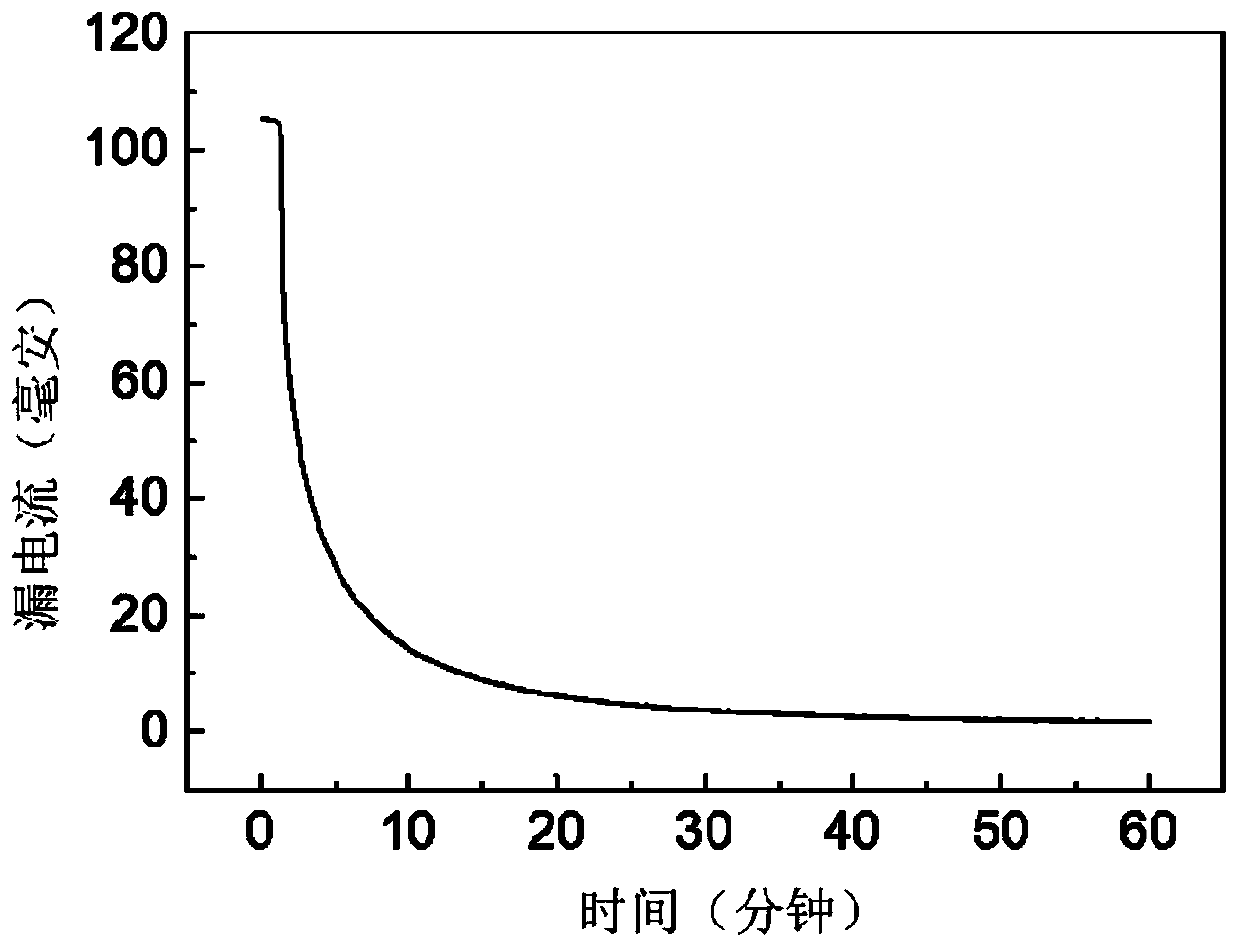

[0037] Example 2 Charge the lithium ion capacitor prepared in Example 1 to 4.15V (here, the current is 1C) with a constant current of 0.5A, charge it at a constant voltage of 4.15V for 180 minutes, discharge it to 2.0V, and then charge it at 0.5A The current is charged at a constant current to 4.0V, and then charged at a constant voltage at 4.0V for 1 hour to obtain a leakage current of 5mA. The test curve of the leakage current of lithium ion capacitor is as follows: figure 2 As shown, the abscissa is the time for testing the leakage current, and the ordinate is the current value during constant voltage charging at a rated voltage of 4.0V. The current value decreases exponentially with the constant voltage charging time, and the current at the end of charging is the leakage current.

Embodiment 3

[0038] Example 3 Charge the lithium-ion capacitor prepared in Example 1 to 4.2V at a constant current of 0.5A, charge at a constant voltage at 4.2V for 5 minutes, discharge to 2.0V, and charge at a constant current of 0.5A to 4.1V , and then charged at a constant voltage of 4.1V for 1 hour to obtain a leakage current of 6.2mA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com