Hot-pressing sintering device, bulk thermoelectric material with micro-nano porous structure and its preparation method

A technology of thermoelectric materials and porous structure, which is applied in the preparation of bulk thermoelectric materials and hot-pressing sintering devices, and can solve the problems of complex operation steps and inability to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This embodiment is used to illustrate Zintl phase thermoelectric material Mg 3.175 mn 0.025 Sb 1.98 Bi 0.5 Te 0.02 and its preparation.

[0082] Firstly, the simple substance particles of each element are ball milled for 12 hours according to the stoichiometry to form a powder with a particle size of 200 nanometers to 10 microns. The conventional spark plasma sintering method sinters the powder into a dense block (this process is a sintering), and the sintering conditions are as follows: vacuum degree 5Pa, pressure 50MPa, heating rate 50℃ / min, sintering temperature 600℃, holding time 5 minute.

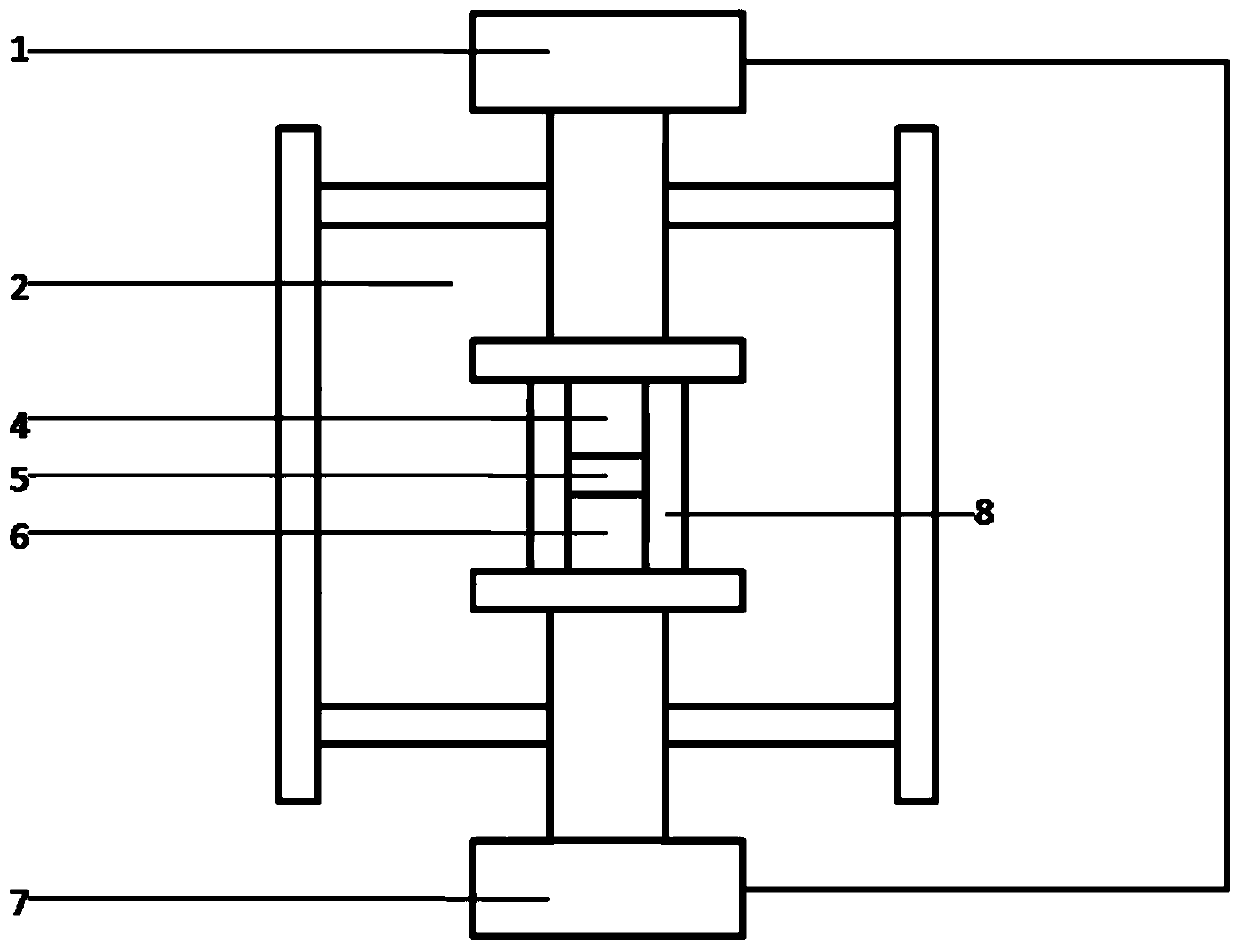

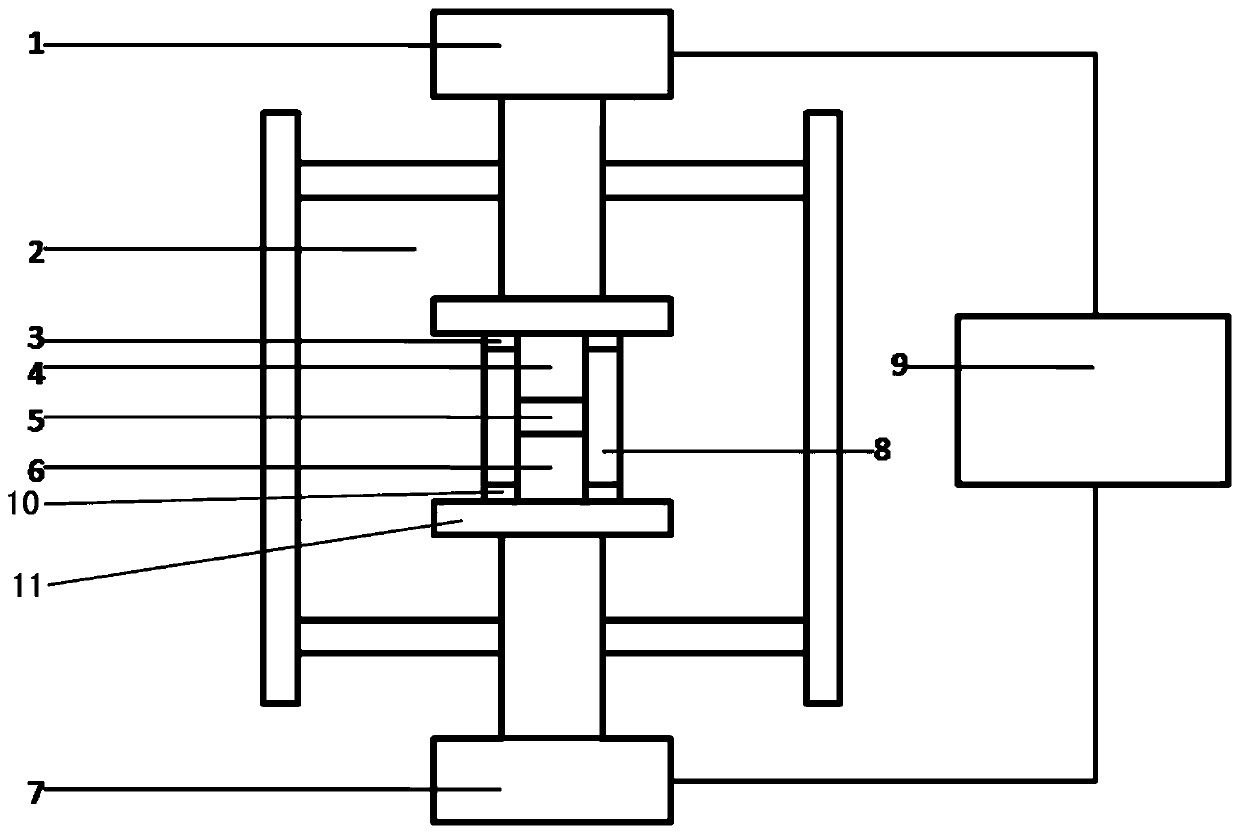

[0083] Then ball mill the primary sintered bulk material for 4 hours to form a raw material powder with a particle size of 200 nanometers to 10 microns. figure 2 Secondary sintering was performed in the device shown to obtain samples with multiscale micro-nanoporous structures. In the secondary sintering, the vacuum degree is 5Pa, the pressure is 50MPa, the heating rate ...

Embodiment 2

[0088] This embodiment is used to illustrate the Half-Heusler alloy thermoelectric material Hf 0.25 Zr 0.75 NiSn 0.99 Sb 0.01 and its preparation.

[0089] First, according to the stoichiometric ratio, the simple substances of each element are arc-melted into ingots, and then ball milled for 12 hours to form a powder with a particle size of 200-600 nanometers. figure 2 Spark plasma sintering is carried out in the device shown, the vacuum degree is 5Pa, the pressure is 60MPa, the heating rate is 40°C / min, the sintering temperature is 900°C, and the holding time is 20 minutes. Samples with scale micro-nanoporous (porous) structures.

[0090] Figure 5 and Figure 6 Representative SEM images of samples of Example 2 at different magnifications are shown. SEM results show that the sample of Example 2 has a multi-scale micro-nano pore (porous) structure. The compactness of the sample of Example 2 is 93%.

[0091] In addition, the FDS-4000 spark plasma sintering furnace joi...

Embodiment 3

[0094] This example is used to illustrate Bi 2 Te 3 Base material Bi 0.5 Sb 1.5 Te 3 and its preparation.

[0095] Firstly, ball mill the elemental particles of each element for 9 hours according to stoichiometry to form a powder with a particle size of 100-300 nanometers. figure 2 Spark plasma sintering is carried out in the device shown, the vacuum degree is 5Pa, the pressure is 50MPa, the heating rate is 70°C / min, the sintering temperature is 450°C, and the holding time is 5 minutes. Samples with scale micro-nanoporous (porous) structures.

[0096] Figure 7 and Figure 8 Representative SEM images of samples of Example 3 at different magnifications are shown. SEM results show that the sample of Example 3 has a multi-scale micro-nano pore (porous) structure. The compactness of the sample of Example 3 is 81%.

[0097] In addition, Bi 0.5 Sb 1.5 Te 3 dense material as a reference sample. Specifically, firstly, according to the stoichiometry, the simple substance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com