Method of using sludge to process nutritional soil

A technology for nutrient soil and sludge, applied in the directions of botanical equipment and methods, culture medium, planting substrate, etc., can solve problems such as environmental pollution, and achieve the effects of environmental protection, promotion and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of sludge processing nutrient soil, comprising the following raw materials: sludge, organic matter, coconut fiber, sludge fermentation agent, EM bacteria, perlite, vermiculite, nutrient soil conditioner; the weight percentage of each component is: sewage Mud 55%, organic matter 15%, coconut fiber 15%, sludge starter 0.1%, EM bacteria 0.1%, perlite 4%, vermiculite 3%, nutrient soil conditioner 8%.

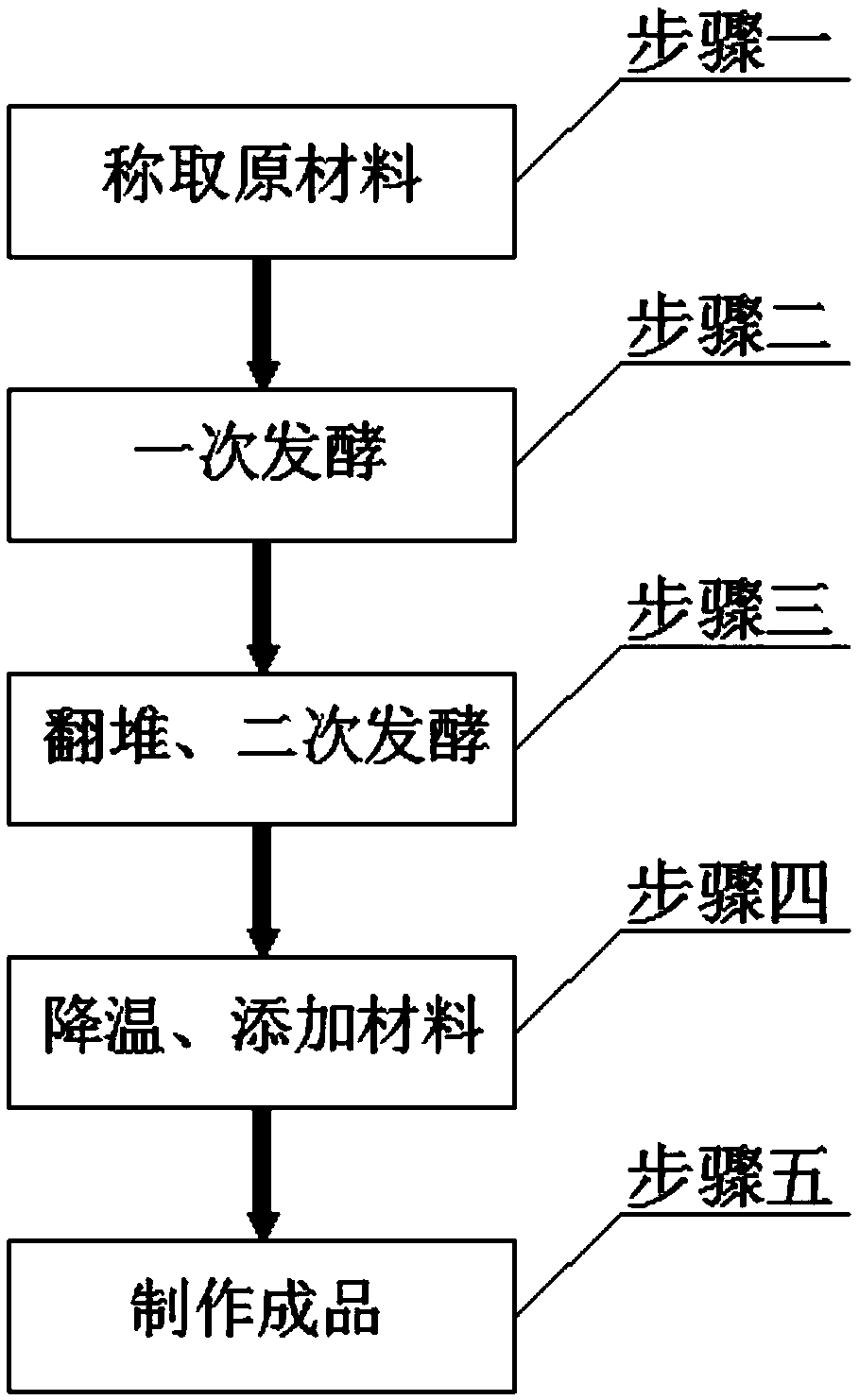

[0040] A method for processing nutrient soil from sludge, comprising the following steps: step 1: weighing raw materials; step 2: primary fermentation; step 3: turning over and secondary fermentation; step 4: cooling down, adding materials; step 5: making finished products ;in:

[0041] In step 1, various raw materials are weighed according to the formula;

[0042] In step 2, sludge, coconut fiber, organic matter with high cellulose content, and nutrient soil conditioner are mixed for heap or tank fermentation;

[0043] In step 3, when the temperature of the fermente...

Embodiment 2

[0047] A kind of sludge processing nutrient soil, comprising following raw materials: sludge, organic matter, coconut fiber, coconut fiber, sludge fermentation agent, EM bacteria, perlite, vermiculite, nutrient soil conditioner; the weight of each component The percentages are: sludge 60%, organic matter 20%, coconut fiber 10%, coconut fiber, sludge starter 0.1%, EM bacteria 0.1%, perlite 2%, vermiculite 1%, nutrient soil conditioner 7% .

[0048] A method for processing nutrient soil from sludge, comprising the following steps: step 1: weighing raw materials; step 2: primary fermentation; step 3: turning over and secondary fermentation; step 4: cooling down, adding materials; step 5: making finished products ;in:

[0049] In step 1, various raw materials are weighed according to the formula;

[0050] In step 2, sludge, coconut fiber, organic matter with high cellulose content, and nutrient soil conditioner are mixed for heap or tank fermentation;

[0051] In step 3, when t...

Embodiment 3

[0055] A kind of sludge processing nutrient soil, comprising following raw materials: sludge, organic matter, coconut fiber, coconut fiber, sludge fermentation agent, EM bacteria, perlite, vermiculite, nutrient soil conditioner; the weight of each component The percentages are: sludge 65%, organic matter 20%, coconut fiber 10%, coconut fiber, sludge starter 0.1%, EM bacteria 0.1%, perlite 4%, vermiculite 3%, nutrient soil conditioner 8% .

[0056] A method for processing nutrient soil from sludge, comprising the following steps: step 1: weighing raw materials; step 2: primary fermentation; step 3: turning over and secondary fermentation; step 4: cooling down, adding materials; step 5: making finished products ;in:

[0057] In step 1, various raw materials are weighed according to the formula;

[0058] In step 2, sludge, coconut fiber, organic matter with high cellulose content, and nutrient soil conditioner are mixed for heap or tank fermentation;

[0059] In step 3, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com