Regenerated concrete production technology

A technology of recycled concrete and manufacturing process, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the high degree of dry shrinkage and creep, affect impermeability, affect strength and overall use Life and other issues, to achieve the effect of enhancing mechanical properties, prolonging service life, and reducing the development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

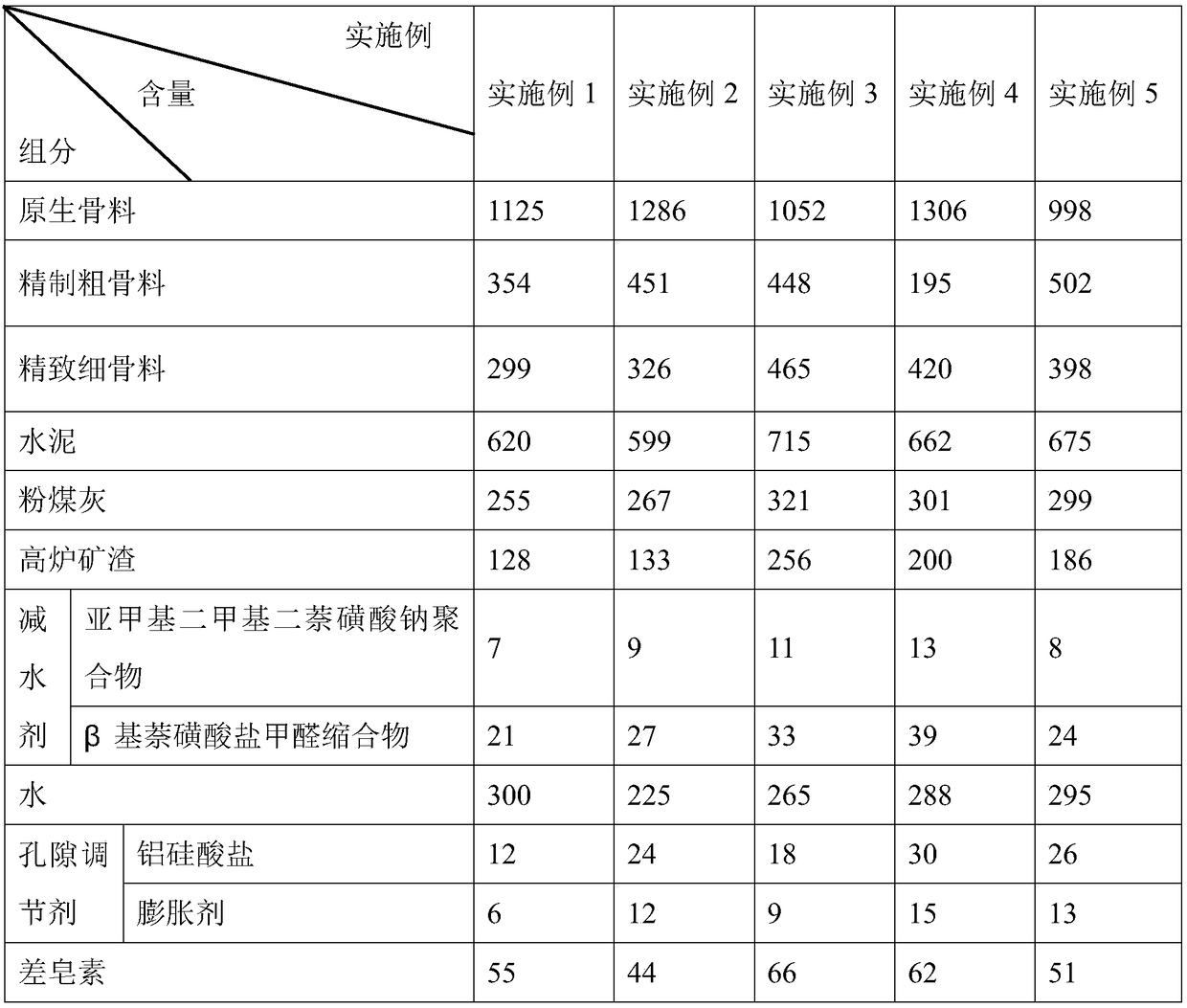

[0041]Examples 1-5, a recycled concrete, include components and corresponding contents as shown in Table 1. Among them, the cement is ordinary Portland cement with a strength grade of 32.5; the particle size of refined coarse aggregate is 5-20mm, and the particle size of refined fine aggregate is 1.5-4mm; Composed of sodium methyldimethyl dinaphthalene sulfonate polymer and β-base naphthalene sulfonate formaldehyde condensate; the gap regulator includes a slow-release agent and an expansion agent with a weight ratio of 1:0.5, and the slow-release agent is treated by carbon dioxide immersion Perfused aluminosilicate, the expansion agent is composed of calcium oxide, calcium sulfoaluminate and magnesium oxide in a weight ratio of 3:1:1.

[0042] Each component and its corresponding content table (kg) in the embodiment 1-5 of table 1

[0043]

Embodiment 6

[0044] Embodiment 6, a recycled concrete, differs from Embodiment 1 in that it does not contain poor saponin.

Embodiment 7

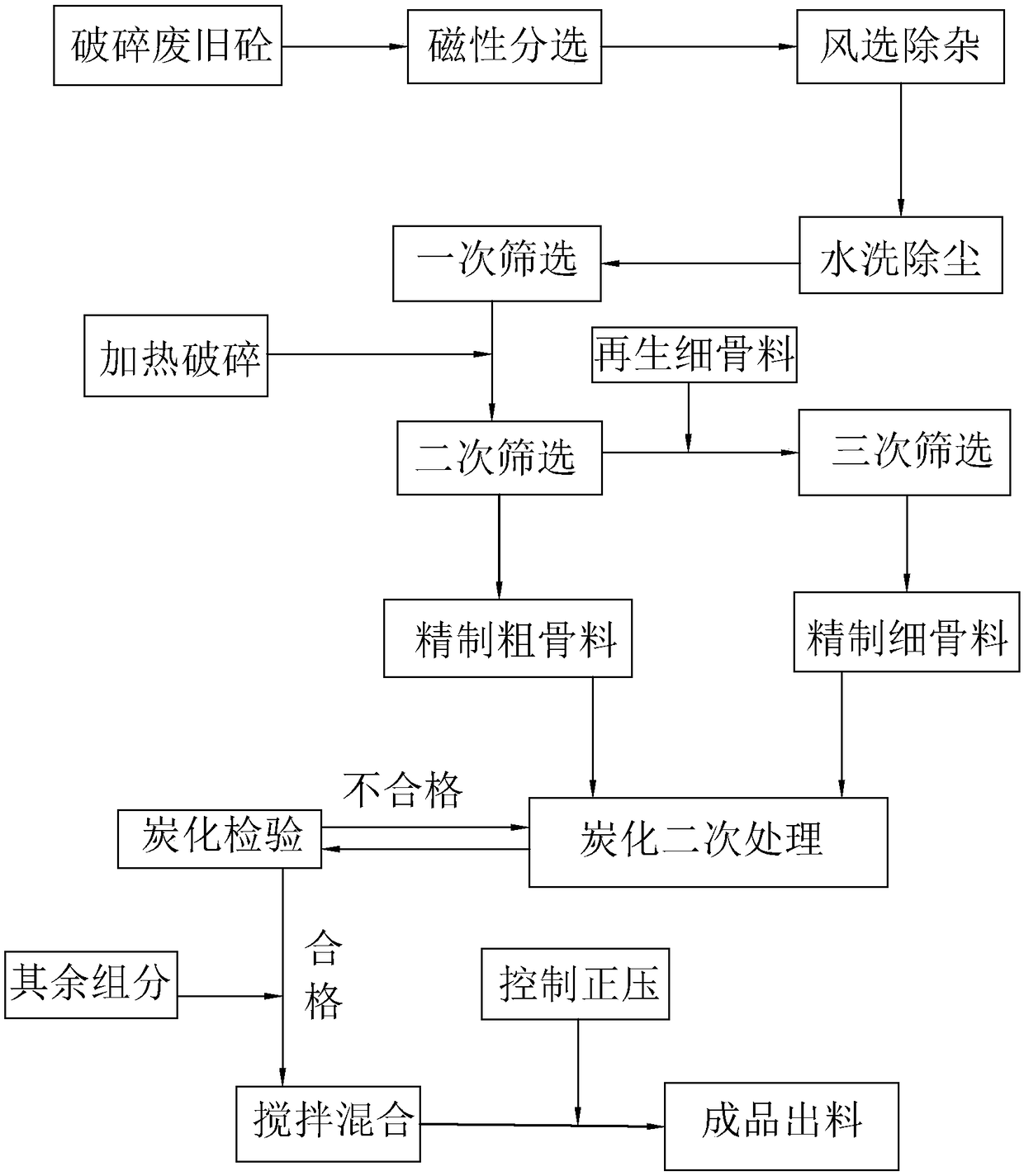

[0045] Embodiment 7, a production process of recycled concrete, the components contained and the corresponding content refer to Example 1, and the steps included are as follows:

[0046] S1, prepare recycled aggregates, crush waste concrete blocks, remove steel bars and sieve to obtain recycled aggregates, and then undergo magnetic separation to remove metal impurities and rust, winnowing and removing impurities to reduce leaves and plants, and water washing and dust removal. Remove the soil to obtain qualified recycled aggregate. At this time, perform a screening to obtain recycled coarse aggregate and recycled fine aggregate, and the particle size of the recycled coarse aggregate is 5-40mm, and the particle size of the recycled fine aggregate is less than 5mm;

[0047] S2, recycled aggregate pretreatment, heating the recycled coarse aggregate and recycled fine aggregate obtained in S1 to 300°C, crushing again, and performing secondary screening after crushing to obtain refine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com