Gear oil for oil pumping unit in oilfield and preparation method thereof

A technology of pumping unit and gear oil, which is applied in the field of low pour point micro-shearing gear oil for oil field pumping units and its preparation, can solve problems such as poor lubrication, abrasion damage, tooth surface abrasion, etc., and achieves the preparation method Simple, long-term effective and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

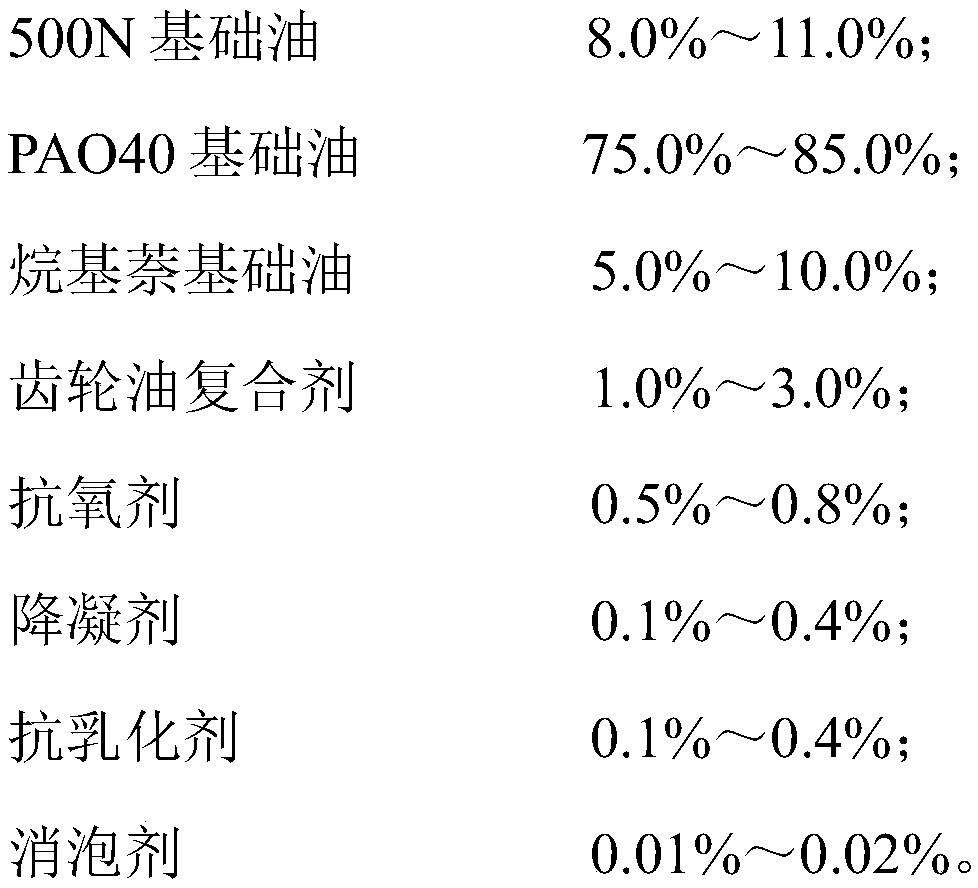

preparation example Construction

[0032] The preparation method of above-mentioned gear oil is as follows:

[0033] Add 500N base oil, PAO40 base oil, and alkylnaphthalene base oil into the blending kettle, add defoamer pulse blending at 45°C-55°C for 10-15 minutes, then add antioxidant and pour point depressant pulse blending Combine for 10-15 minutes, then add compounding agent, keep pulse blending at 45°C-55°C for 100-150 minutes, settle for 100-150 minutes, and filter to obtain low pour point micro-shear gear oil for oilfield pumping units.

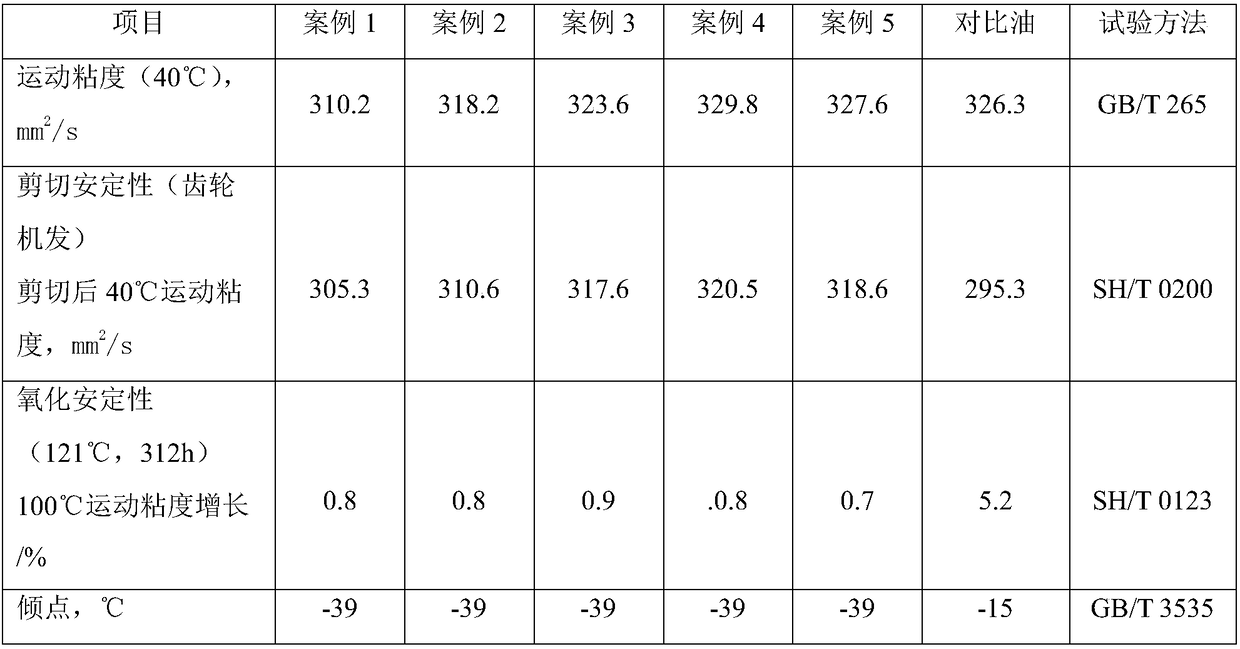

Embodiment example 1

[0036] Low-temperature micro-shear gear oil for pumping units in oilfields, composed of the following components in parts by mass: 500N base oil 9.49%; PAO40 base oil 80%; alkylnaphthalene base oil 8%; gear oil compounding agent 1.6% Antioxidant 0.5%; pour point depressant 0.3%; anti-emulsifier 0.1%; 2,2'-thiobis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid The mass ratio of ethyl ester] to nonyl diphenylamine is 1:1; the mixture of polymethacrylate and polya-olefin (trade name: T803B) as pour point depressant, and the mixture of polymethacrylate and polya-olefin (commodity name: T803B) Name: T803B), the mass ratio is 1:1, the anti-emulsifier is Lubrizol 5957, and the defoamer is polydimethylsiloxane.

[0037] The preparation method of described gear oil:

[0038] Add 500N base oil, PAO40 base oil, and alkylnaphthalene base oil into the blending kettle, add defoamer and pulse blend for 10 minutes at 45°C, then pulse blend for 10 minutes with antioxidant and pour point...

Embodiment example 2

[0040] Low-temperature micro-shear gear oil for pumping units in oil fields, composed of the following components in parts by mass: 500N base oil 9.49%; PAO40 base oil 81%; alkylnaphthalene base oil 7%; gear oil compounding agent 1.6% Antioxidant 0.5%; pour point depressant 0.3%; anti-emulsifier 0.1%; 2,2'-thiobis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid The mass ratio of ethyl ester] to nonyl diphenylamine is 1:1; the mixture of polymethacrylate and polya-olefin (trade name: T803B) as pour point depressant, and the mixture of polymethacrylate and polya-olefin (commodity name: T803B) Name: T803B), the mass ratio is 1:1, the anti-emulsifier is Lubrizol 5957, and the defoamer is polydimethylsiloxane.

[0041] The preparation method of described gear oil:

[0042] Add 500N base oil, PAO40 base oil, and alkylnaphthalene base oil into the blending kettle, add defoamer and pulse blend for 12 minutes at 48°C, then pulse blend for 12 minutes with antioxidant and pour poin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com