Water granulated slag XRF (x-ray fluorescence) quantitative analysis method

A quantitative analysis and slag technology, applied in the analysis of materials, material analysis using wave/particle radiation, measuring devices, etc., can solve the problems of large deviations in quantitative analysis results and reduced strength ratios, and reduce sample pretreatment time, ease of handling, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: XRF Quantitative Analysis of Water Slag in Nanjing Iron and Steel Plant

[0048] 1. Establishment of quantitative analysis model for water slag

[0049] (1) Provide 6 water slag standard sample powders, weigh 12g of water slag standard sample powder for each powder sample, put it into an XRF sample cup and apply a 40kpa pressure to compact the sample, and prepare 6 water slag standard samples.

[0050] (2) Adopt X-ray fluorescence spectrometry to detect water slag standard samples, establish a standard curve based on the obtained data, and the obtained calibration curve equation is:

[0051] C=(Id +57725) / 57788

[0052] C-element content;

[0053] I d -Characteristic X-fluorescence intensities of elements in dried slag samples.

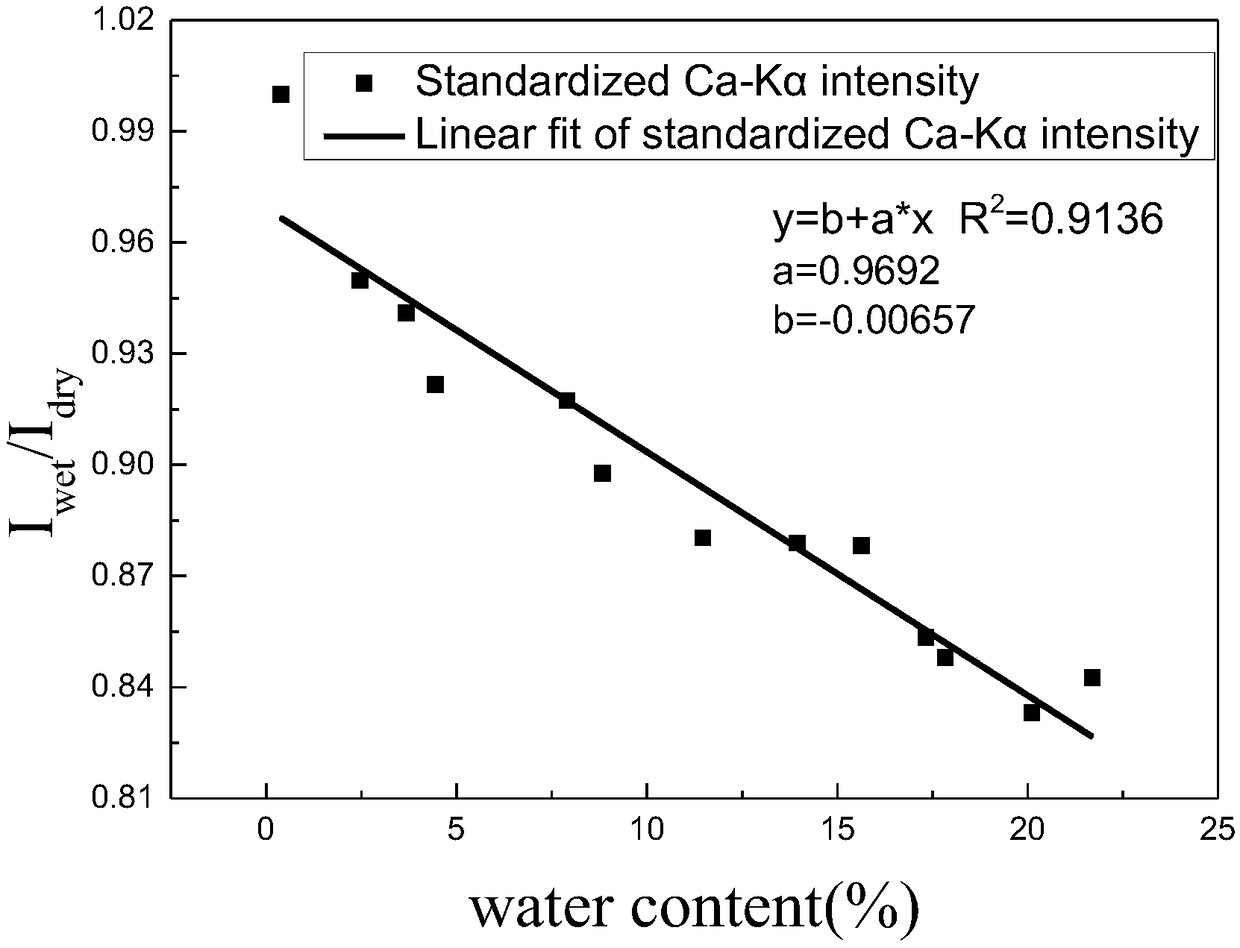

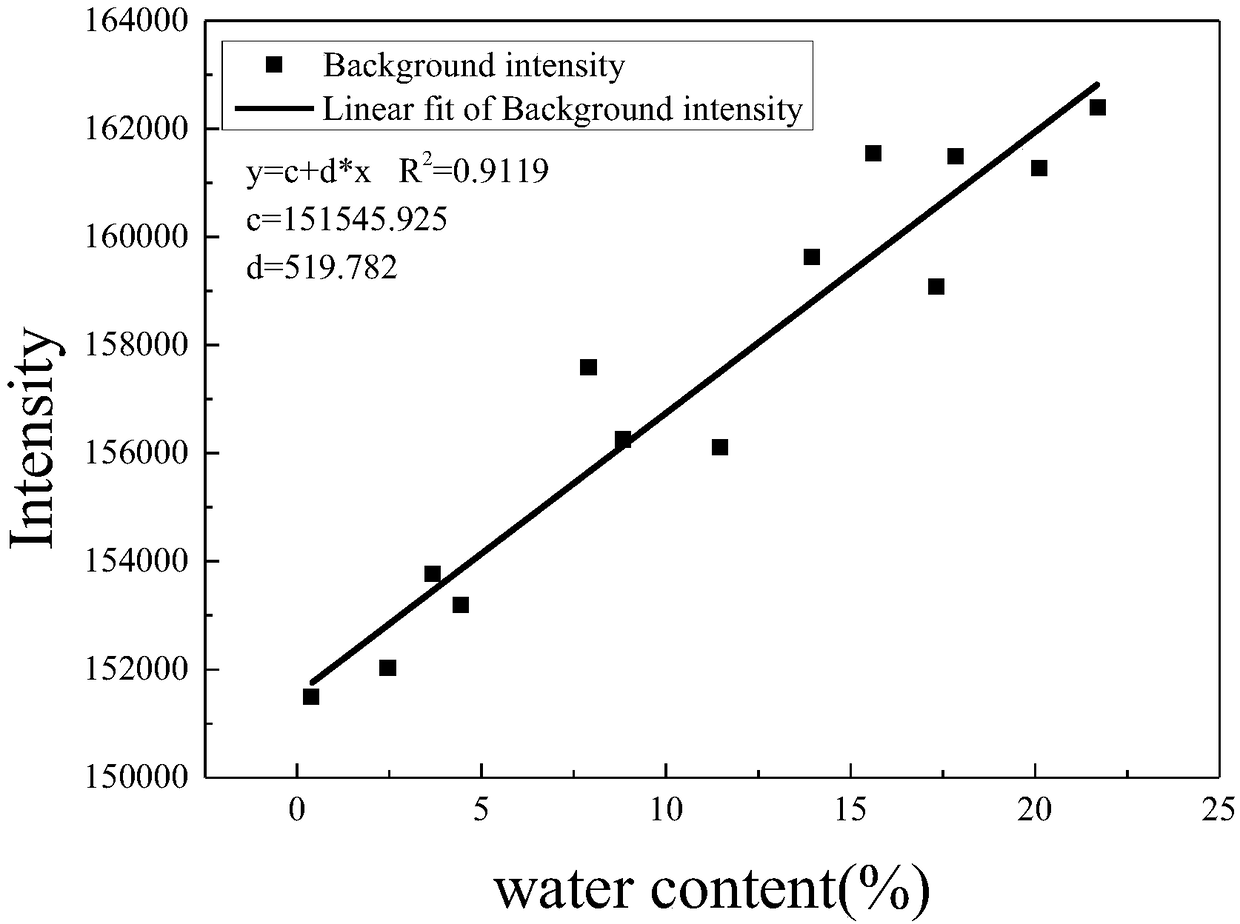

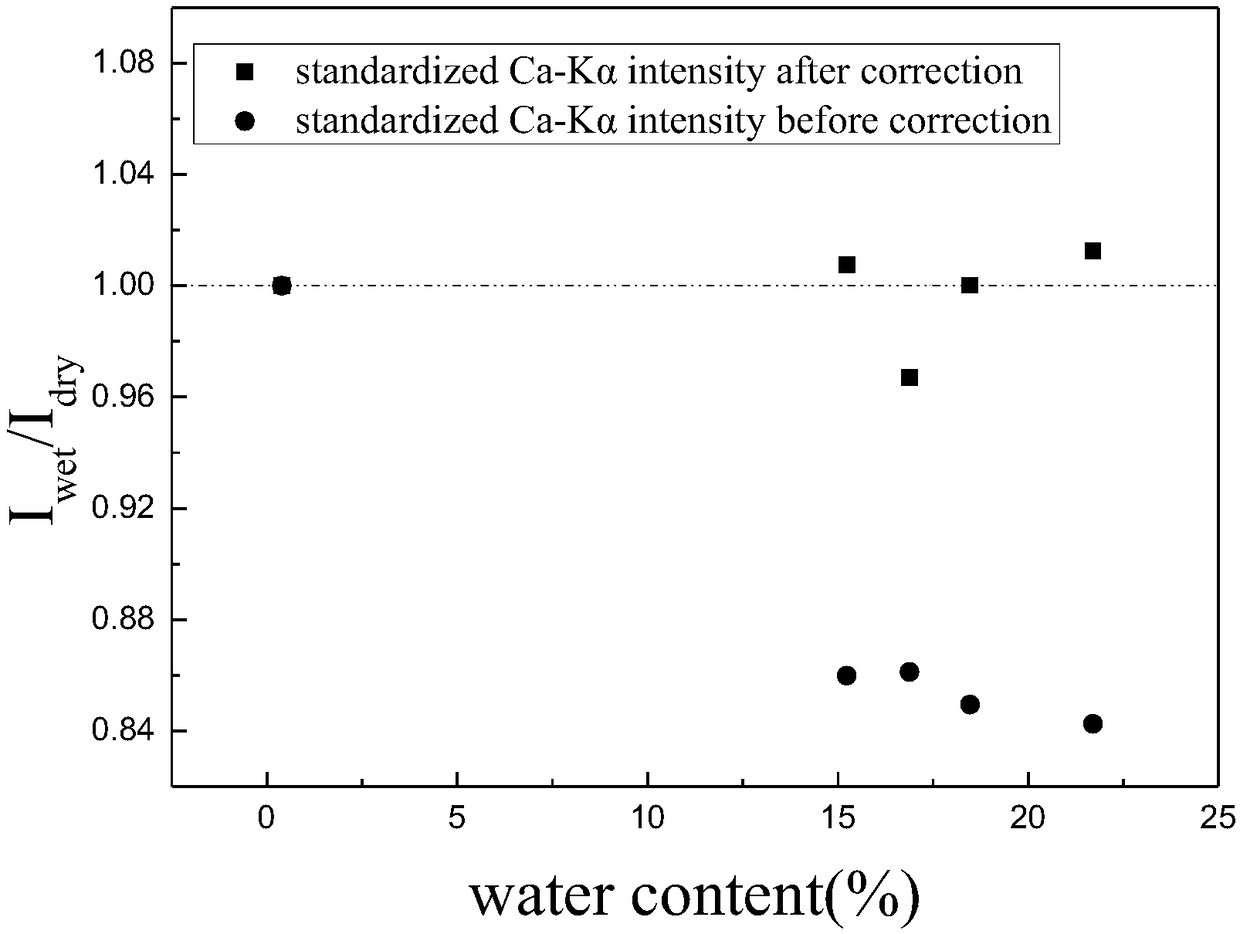

[0054] 2. Establishment of moisture content correction model

[0055] (1) After fully mixing and stirring the water slag powder and distilled water, a water slag sample with a moisture content of 35% is prepared. Evenly smear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com