A lead foil leads out a conductive polymer aluminum electrolytic capacitor

A technology of conductive polymer and aluminum electrolytic capacitors, which is applied in the direction of capacitor terminals, capacitor parts, etc., can solve the problems that affect the capacity extraction rate, loss and ESR, and cannot form a continuous electrolyte layer, so as to improve the size of the monomer, Effect of increasing cell capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

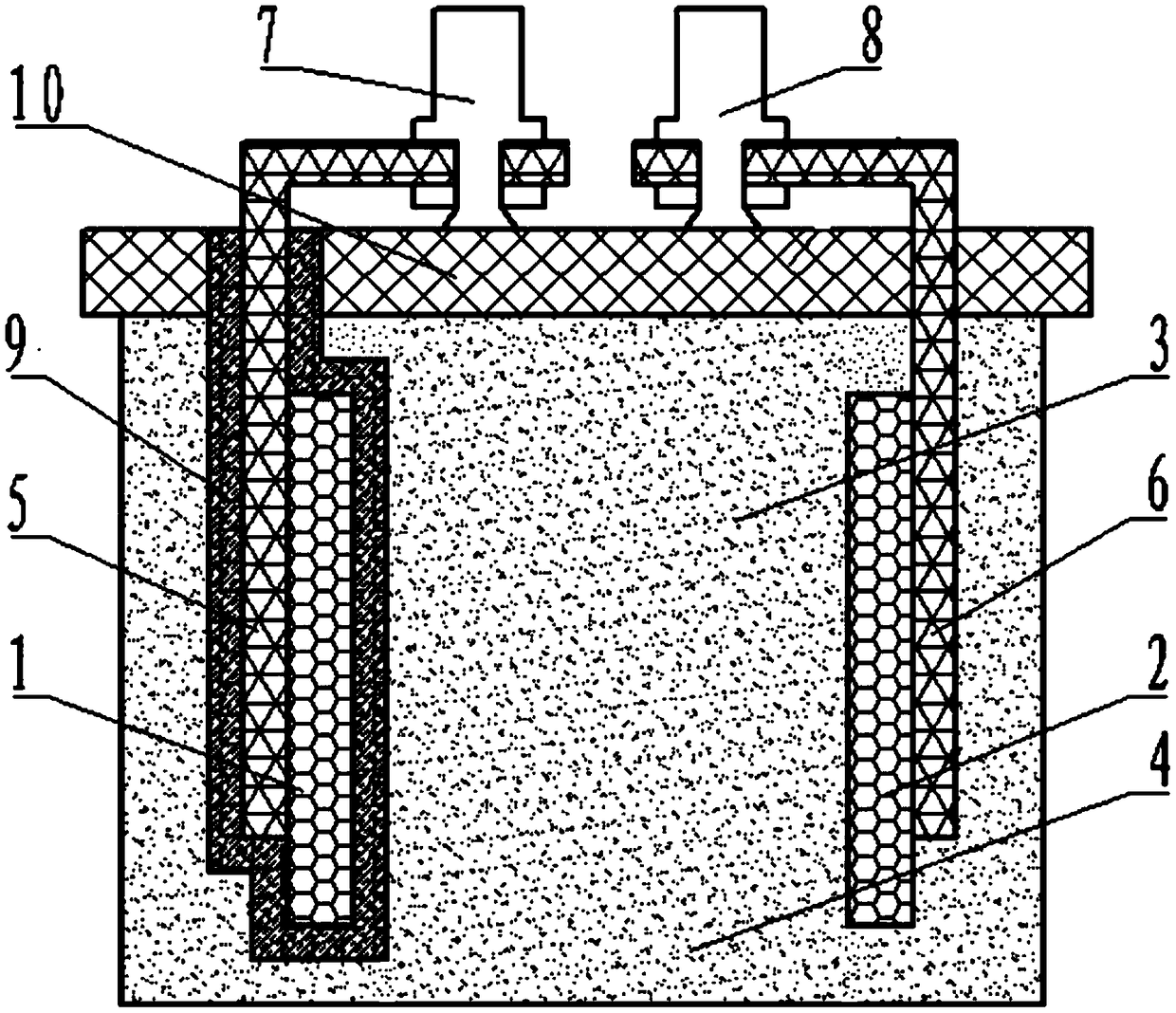

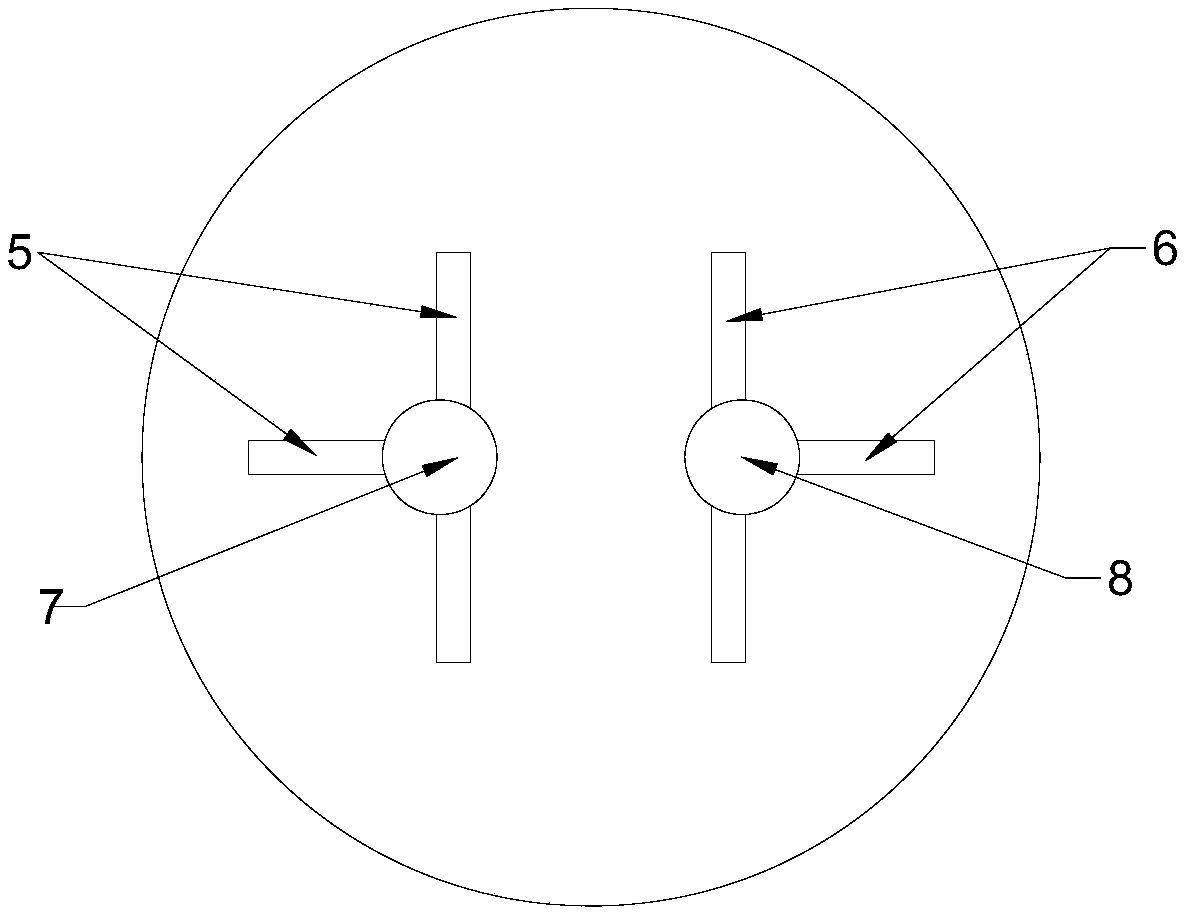

[0035] like figure 1 and figure 2 As shown, the embodiment provides a conductive polymer aluminum electrolytic capacitor led by a guide foil, including:

[0036] A capacitor core wound by an anode electrode foil 1, a cathode electrode foil 2, and a separator paper 3 arranged between the anode electrode foil 1 and the cathode electrode foil 2. The conductive polymer 4 is arranged on the anode electrode foil 1 and the cathode electrode foil 2, the conductive polymer 4 is filled with the surface of the cathode electrode foil 2, the surface of the anode electrode foil 1 and the surface of the separator paper 3;

[0037]The anode lead-out guide foil 5 is riveted on the anode electrode foil 1, and the cathode lead-out guide foil 6 is riveted on the cathode electrode foil 2; an isolation layer 10 is arranged above the isolation paper 3, and the isolation layer 10 is an insulating material, and the isolation layer 10 is A rubber plate formed by rubber potting, with a thickness of 5...

Embodiment 2

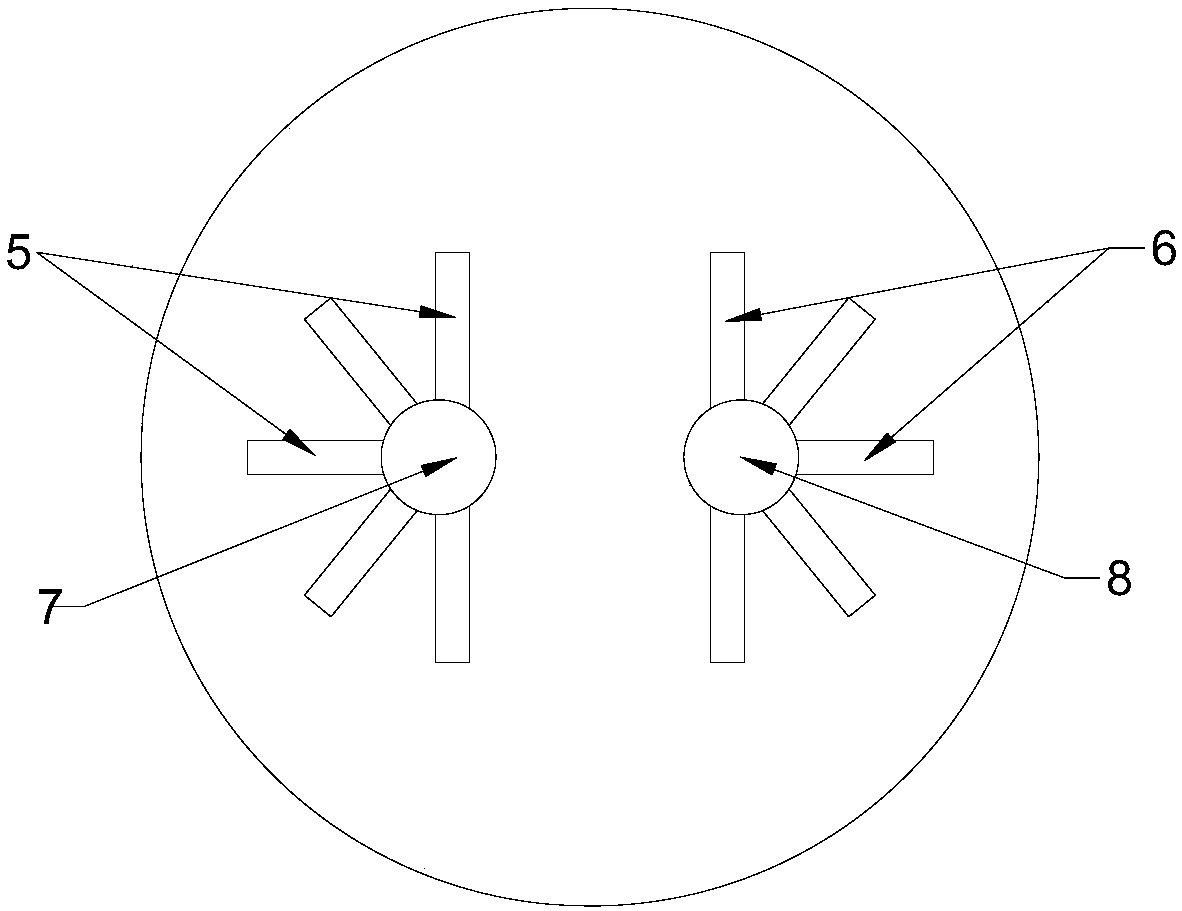

[0061] like figure 1 and image 3 As shown, the embodiment provides a conductive polymer aluminum electrolytic capacitor led by a guide foil, including:

[0062] A capacitor core wound by anode electrode foil 1, cathode electrode foil 2, and separator paper 3 arranged between the anode electrode foil 1 and cathode electrode foil 2. Conductive polymer 4 is arranged on the anode electrode foil 1, cathode electrode foil 2, the conductive polymer 4 is filled with the surface of the cathode electrode foil 2, the surface of the anode electrode foil 1 and the surface of the separator paper 3;

[0063] The anode lead-out guide foil 5 is riveted on the anode electrode foil 1, and the cathode lead-out guide foil 6 is riveted on the cathode electrode foil 2; an isolation layer 10 is arranged above the isolation paper 3, and the isolation layer 10 is an insulating material. Layer 10 is a rubber plate formed by rubber potting, with a thickness of 6mm. The positive lead-out terminal 7 and...

Embodiment 3

[0075] like figure 1 and figure 2 As shown, the embodiment provides a conductive polymer aluminum electrolytic capacitor led by a guide foil, including:

[0076] A capacitor core wound by anode electrode foil 1, cathode electrode foil 2, and separator paper 3 arranged between the anode electrode foil 1 and cathode electrode foil 2. Conductive polymer 4 is arranged on the anode electrode foil 1, cathode electrode foil 2, the conductive polymer 4 is filled with the surface of the cathode electrode foil 2, the surface of the anode electrode foil 1 and the surface of the separator paper 3;

[0077] The anode lead-out guide foil 5 is riveted on the anode electrode foil 1, and the cathode lead-out guide foil 6 is riveted on the cathode electrode foil 2; an isolation layer 10 is arranged above the isolation paper 3, and the isolation layer 10 is an insulating material. Layer 10 is a rubber plate formed by rubber potting, with a thickness of 10 mm. The positive lead-out terminal 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com