Preparation method of white light chip

A chip and white light technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems such as the utilization rate of light has not been effectively improved, with yellow or blue light spots, LED chips can not reach, etc., to achieve luminous Small angle, low cost, uniform spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This embodiment adopts the following steps:

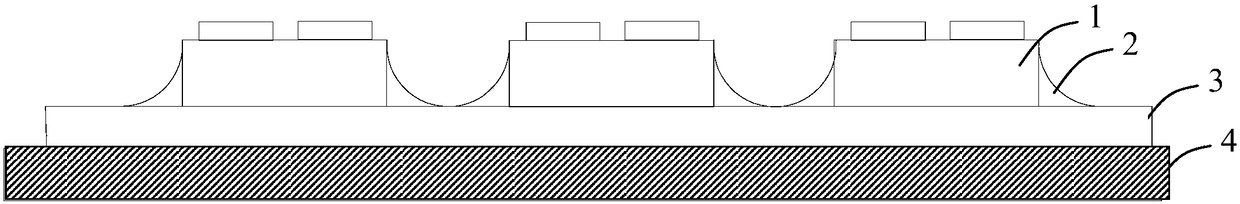

[0022] Prepare and select a fluorescent film 3 that meets the requirements, and electroplate metal on the electrode of the flip-chip blue LED chip 1 as a metal electrode. Place the fluorescent film 3 on the support substrate 4, and then dot transparent silica gel on the surface of the fluorescent film 3 according to preset rules, such as uniformly spot transparent silica gel 2 of the same size on the surface of the fluorescent film 3; after that, prepare the metal electrode The flip-chip blue LED chip 1 (the surface on the side where the metal electrode is not prepared) is placed on the position of the transparent silica gel in the fluorescent film, and baked at a temperature of 150° for 2 hours, so that the surface around the flip-chip blue LED chip The transparent silica gel 2 presents a concave arc shape, such as figure 1 shown;

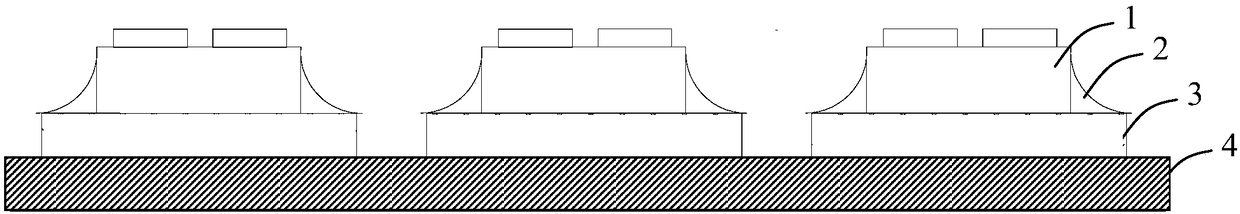

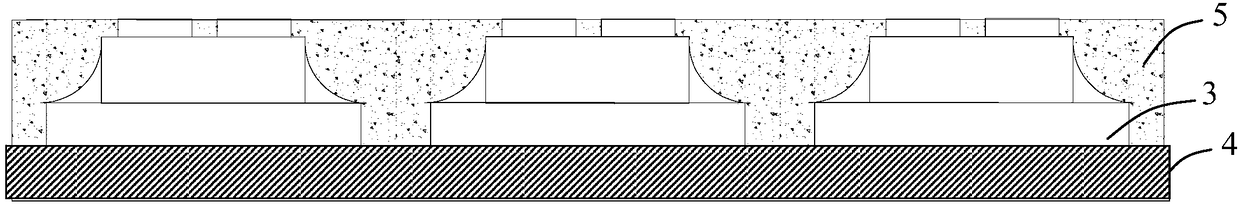

[0023] Cut the fluorescent film 3 along the cutting line, and expand the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com