A back-to-back assembly for a photovoltaic power station and a manufacturing method thereof

A photovoltaic power station and photovoltaic cable technology, which is applied in the collection field of solar backplane DC current for photovoltaic power stations, can solve problems such as complex installation, high cost, and large contact resistance, and achieve high electrical insulation performance, low cost, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

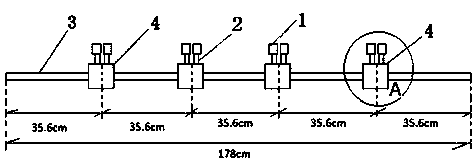

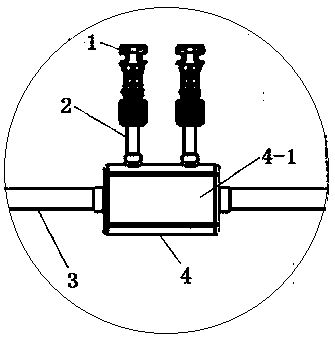

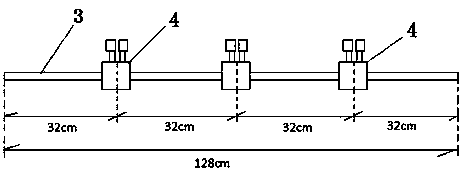

[0034] Such as Figure 1 to Figure 7 As shown, a back-to-back assembly for a photovoltaic power station includes a solar connector 1 , a photovoltaic cable 2 , an aluminum alloy cable 3 , and a confluence joint 4 .

[0035] The photovoltaic cable 2 is composed of a halogen-free flame-retardant photovoltaic cable radiation insulating layer 2-2 and a halogen-free flame-retardant photovoltaic cable radiation sheath 2-3 on the outside of a stranded tinned copper core conductor 2-1. The aluminum alloy cable 3 is composed of an aluminum alloy conductor 3-1 with a cross-linked polyolefin insulating layer 3-2 and a cross-linked polyolefin outer sheath 3-3 in sequence.

[0036] Two photovoltaic cables 2 are a pair, on the aluminum alloy cable between the two ends of an aluminum alloy cable 3, there are three or four exposed aluminum alloy conductors 3-1 at intervals, three or four exposed aluminum alloy conductors 3-1 are respectively connected to two tinned copper core conductors 2-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com