Built-in longitudinal heat dissipation ceramic block print circuit board and circuit assembly provided with that circuit board

A technology for printed circuit boards and ceramic blocks, applied in the directions of printed circuit components, printed circuits, printed circuits, etc., can solve the problems of expensive machines, inability to reduce the width and spacing of wires, and process limitations, so as to reduce the area of ceramic materials, Good thermal conductivity, increase the effect of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The aforementioned and other technical content, features and effects of the present invention will be clearly presented in the following detailed description of the preferred embodiments in conjunction with the accompanying drawings; in addition, in each embodiment, the same elements will be similar The label indicates.

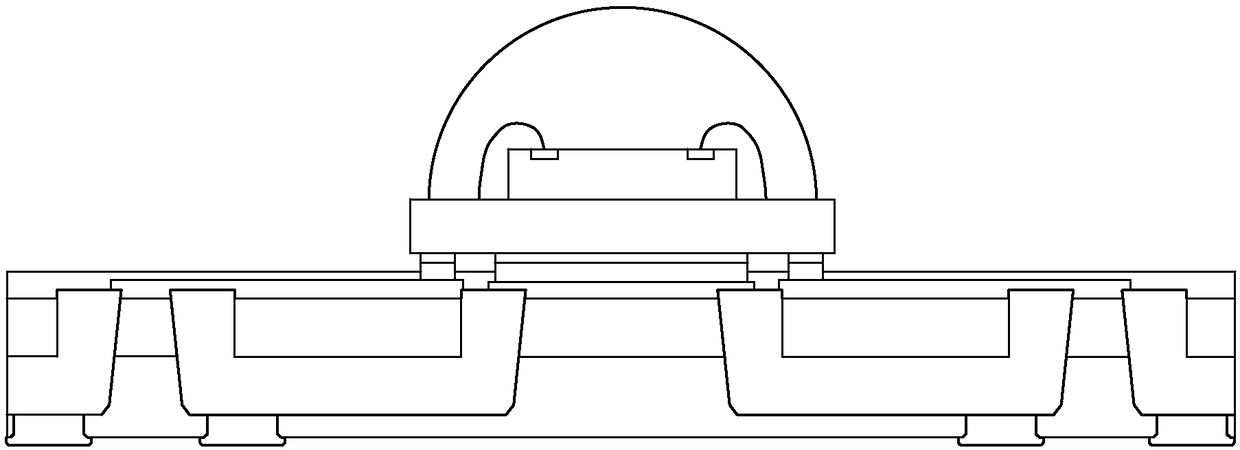

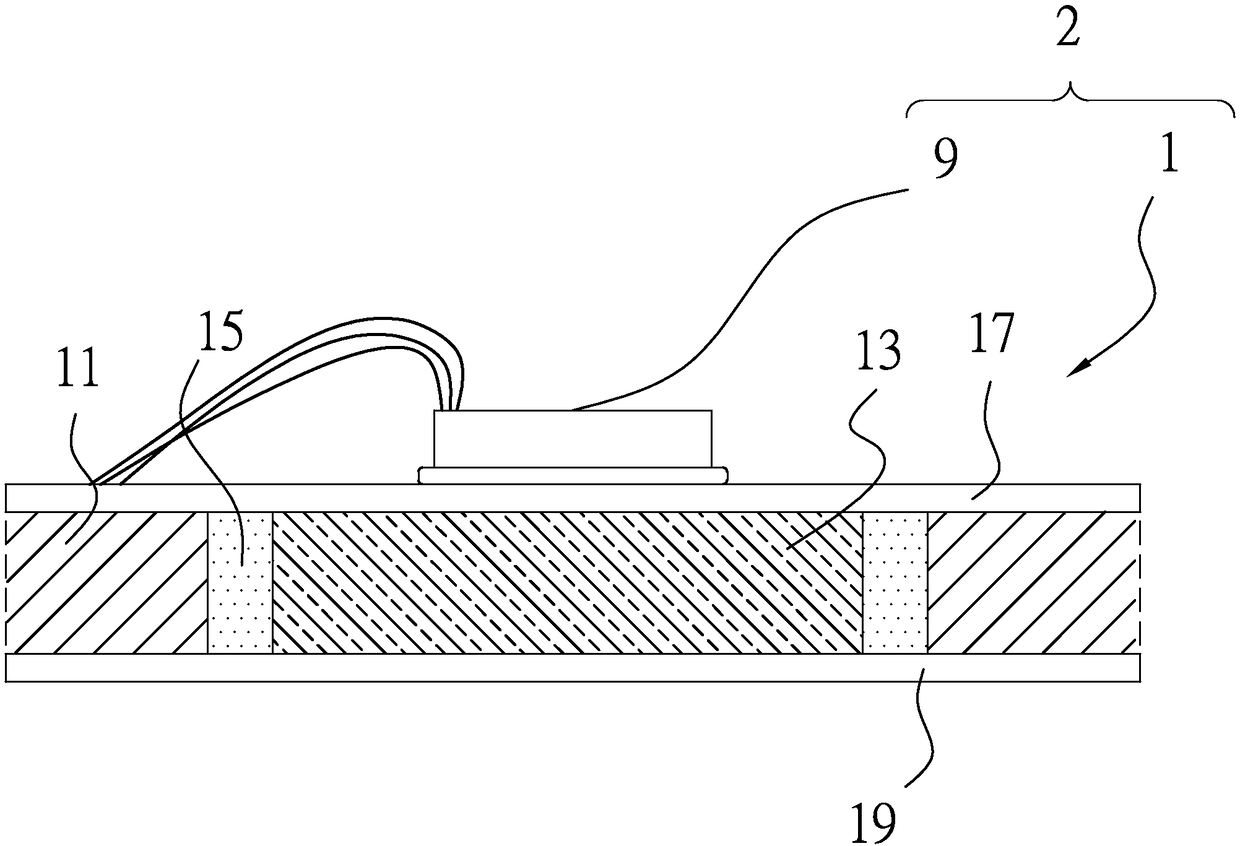

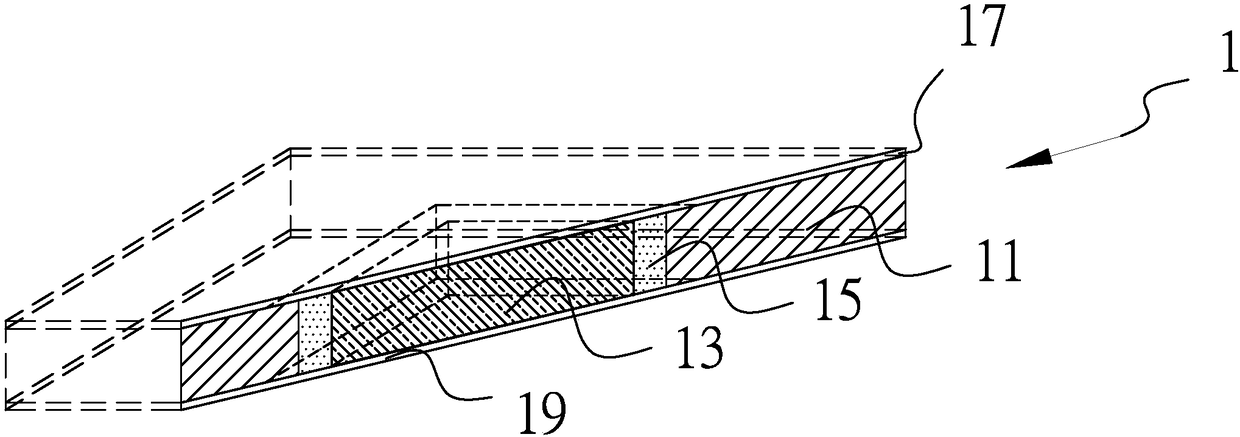

[0039] A first preferred embodiment of a printed circuit board with a built-in vertical heat dissipation ceramic block of the present invention and a circuit assembly with the printed circuit board, such as Figure 2 to Figure 5 As shown, it is based on the multi-layer dielectric material layer 11 of FR-4 with a length and a width of 10 cm. In the dielectric material layer 11, for example, a through hole 115 with a length and a width of 2 cm is pre-cut in the dielectric material layer 11. Then the corresponding aluminum oxide (Al 2 o 3 ) The heat-dissipating ceramic block 13 made of a square column is embedded in the through hole 115 . However, as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com