Lotus seed drying method

A drying method and technology for lotus seeds, which are applied in the direction of preserving seeds through drying, can solve the problems of long drying time, gelatinization of lotus seed starch, and low efficiency, and achieve the effects of improving drying rate, no rehydration rate, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

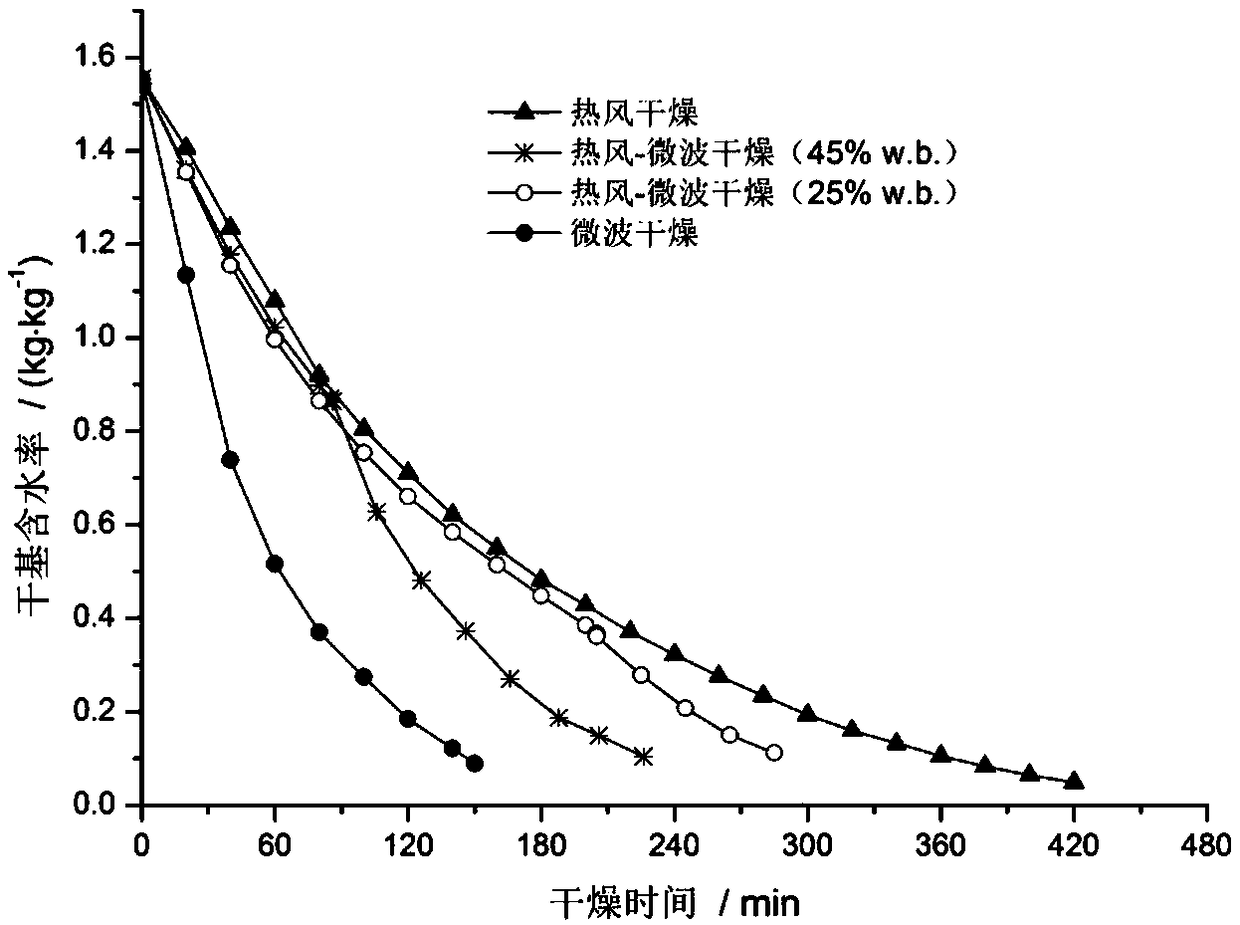

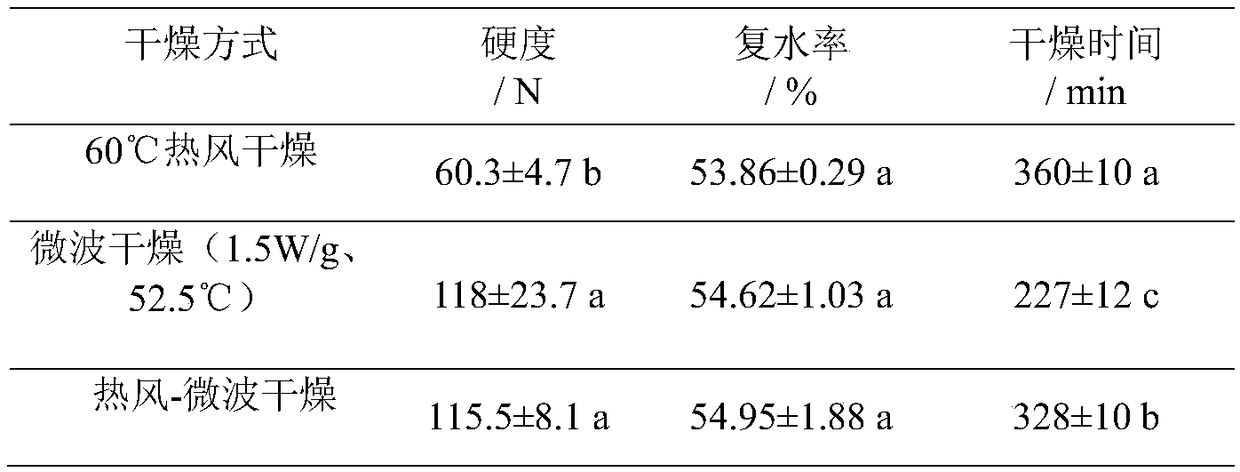

[0019] The lotus seed variety is Jiangxi Guangchang Bailian. The lotus shells were peeled off with a lotus seed peeling machine to obtain fresh lotus seeds, and the lotus seeds were placed in a hot air drying device. The drying conditions were set at a drying temperature of 60 °C and a wind speed of 1 m / s. The water content of lotus seeds on a wet basis was obtained by weighing at 105 °C. When the moisture content of the lotus seeds on a wet basis drops to 29%, the lotus seeds are dried by microwave to the end of drying. The microwave drying conditions are: specific power 1.5W / g, drying wind speed 1m / s, surface temperature range 50℃-55℃. The average drying time is 328min, the product hardness is 115.5N, and the rehydration rate is about 54.95%.

Embodiment 2

[0021] The lotus seed variety is Jiangxi Guangchang Bailian. The lotus shells were peeled off with a lotus seed peeling machine to obtain fresh lotus seeds, and the lotus seeds were placed in a hot air drying device. The drying conditions were set at a drying temperature of 60 °C and a wind speed of 1 m / s. The water content of lotus seeds on a wet basis was obtained by weighing at 105 °C. When the water content of the lotus seeds on a wet basis drops to 35%, the lotus seeds are dried by microwave to the end of drying. The microwave drying conditions are specific power 2W / g, drying wind speed 1m / s, surface temperature range 55°C-60°C. The average drying time is 233min, the product hardness is 118.3N, and the rehydration rate is about 54.53%.

Embodiment 3

[0023] The lotus seed variety is Jiangxi Guangchang Bailian. The lotus shells were peeled off with a lotus seed peeling machine to obtain fresh lotus seeds, and the lotus seeds were placed in a hot air drying device. The drying conditions were set at a drying temperature of 60 °C and a wind speed of 1 m / s. The water content of lotus seeds on a wet basis was obtained by weighing at 105 °C. When the water content of the lotus seeds on a wet basis drops to 25%, the lotus seeds are dried by microwave to the end of drying. The microwave drying conditions are specific power of 1W / g, drying wind speed of 1m / s, and surface temperature range of 50°C-55°C. The average drying time is 323min, the product hardness is 102.7N, and the rehydration rate is about 53.92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap