Preparation method of edible fungi nutrient powder rich in amino acids

A technology of edible mushroom powder and edible mushroom, applied in the direction of food science, can solve the problems of difficulty in adapting to the diversity of edible mushroom products, multi-level needs, few famous products and high value-added products, and the overall level of deep processing of edible mushrooms is not high. , to achieve the effect of reducing drying time, high fluidity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

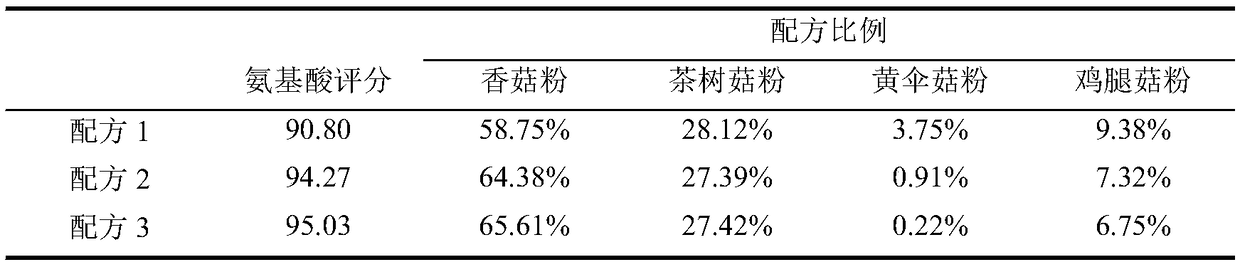

Embodiment 1

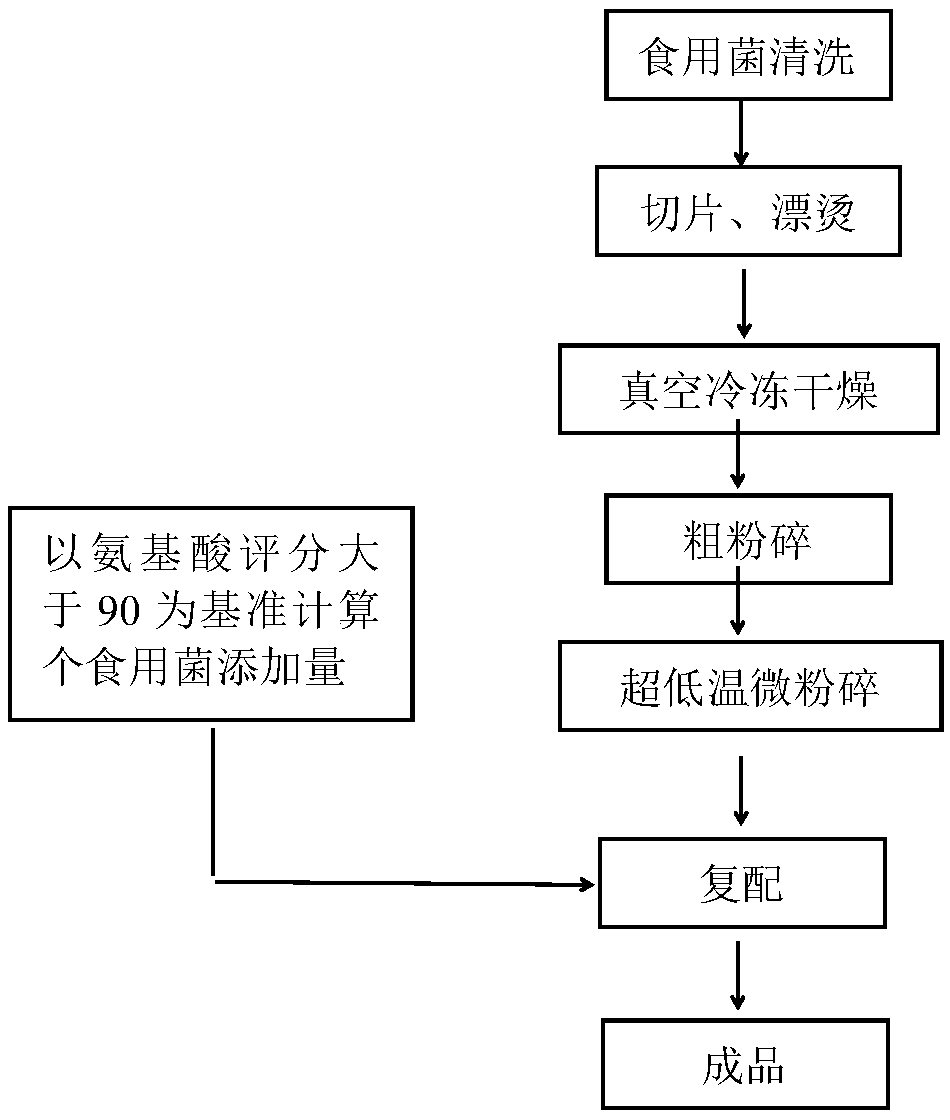

[0046] refer to figure 1 Shown flow chart, a kind of preparation method of edible fungus nutrient powder rich in amino acid, comprises the following steps:

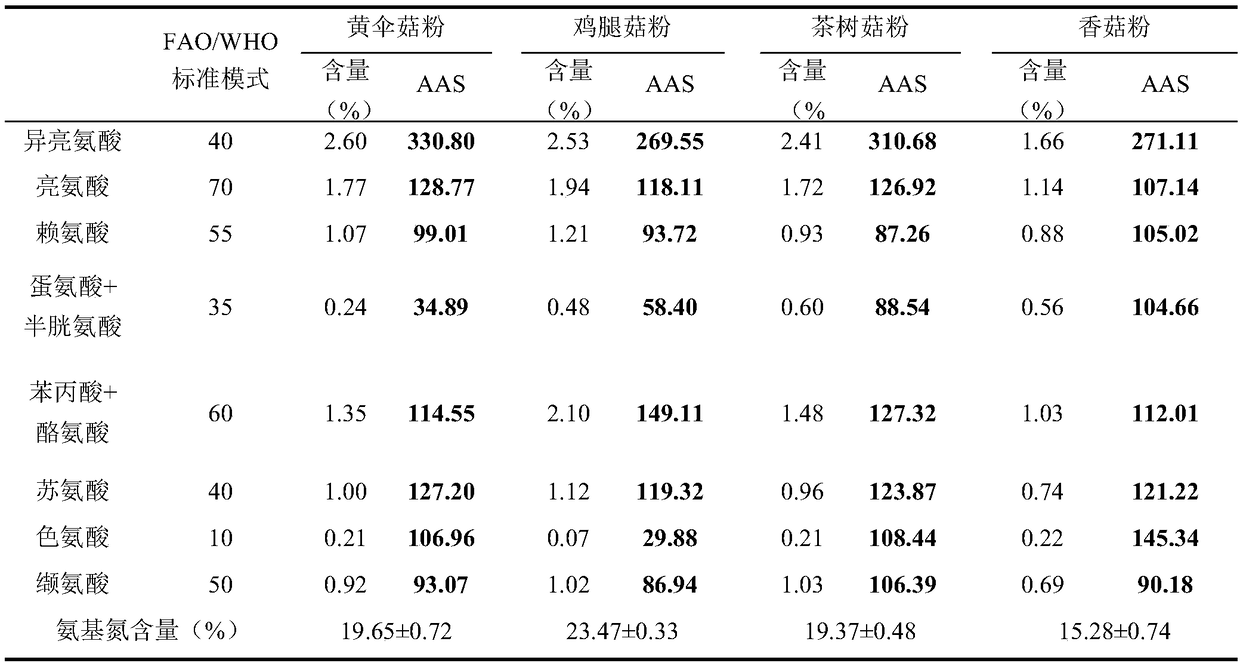

[0047] 1) Screening of raw materials: Select fresh four kinds of edible mushrooms: shiitake mushroom, tea tree mushroom, yellow umbrella mushroom and Coprinus comatus. The meat is thick, tough and elastic, without black spots and impurities. Dry appearance, pure color, no moist feeling and no peculiar smell;

[0048] 2) Pretreatment: Rinse the edible fungus with running water, remove impurities on the surface and slice into slices with a thickness of 3-5mm;

[0049] 3) Blanching: blanching the washed edible fungus in boiling water for 2-3 minutes, and then letting it air for 10 minutes;

[0050] 4) Vacuum freeze-sublimation drying: use vacuum freeze-sublimation drying technology to process blanched edible fungi, and the vacuum degree is less than 0.08mpa;

[0051] Phase one:

[0052] Pre-freezing: Take a certain amount...

Embodiment 2

[0061] refer to figure 1 Shown flow chart, a kind of preparation method of edible fungus nutrient powder rich in amino acid, comprises the following steps:

[0062] 1) Screening of raw materials: Select fresh four kinds of edible mushrooms: shiitake mushroom, tea tree mushroom, yellow umbrella mushroom and Coprinus comatus. The meat is thick, tough and elastic, without black spots and impurities. Dry appearance, pure color, no moist feeling and no peculiar smell;

[0063] 2) Pretreatment: Rinse the edible fungus with running water, remove impurities on the surface and slice into slices with a thickness of 3-5mm;

[0064] 3) Blanching: blanching the washed edible fungus in boiling water for 2-3 minutes, and then letting it air for 10 minutes;

[0065] 4) Vacuum freeze-sublimation drying: use vacuum freeze-sublimation drying technology to process blanched edible fungi, and the vacuum degree is less than 0.08mpa;

[0066] Phase one:

[0067] Pre-freezing: Take a certain amou...

Embodiment 3

[0076] refer to figure 1 Shown flow chart, a kind of preparation method of edible fungus nutrient powder rich in amino acid, comprises the following steps:

[0077] 1) Screening of raw materials: Select fresh four kinds of edible mushrooms: shiitake mushroom, tea tree mushroom, yellow umbrella mushroom and Coprinus comatus. The meat is thick, tough and elastic, without black spots and impurities. Dry appearance, pure color, no moist feeling and no peculiar smell;

[0078] 2) Pretreatment: Rinse the edible fungus with running water, remove impurities on the surface and slice into slices with a thickness of 3-5mm;

[0079] 3) Blanching: blanching the washed edible fungus in boiling water for 2-3 minutes, and then letting it air for 10 minutes;

[0080] 4) Vacuum freeze-sublimation drying: use vacuum freeze-sublimation drying technology to process blanched edible fungi, and the vacuum degree is less than 0.08mpa;

[0081] Phase one:

[0082] Pre-freezing: Take a certain amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com