Damping type high polymer material bearing machining machine tool capable of cleaning chippings efficiently

A polymer material and bearing processing technology, applied in the field of lathes, can solve the problems affecting the bearing processing accuracy, operators cutting fingers, and debris accumulation, etc., to achieve simple processing, stable shock absorption process, and ensure the effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

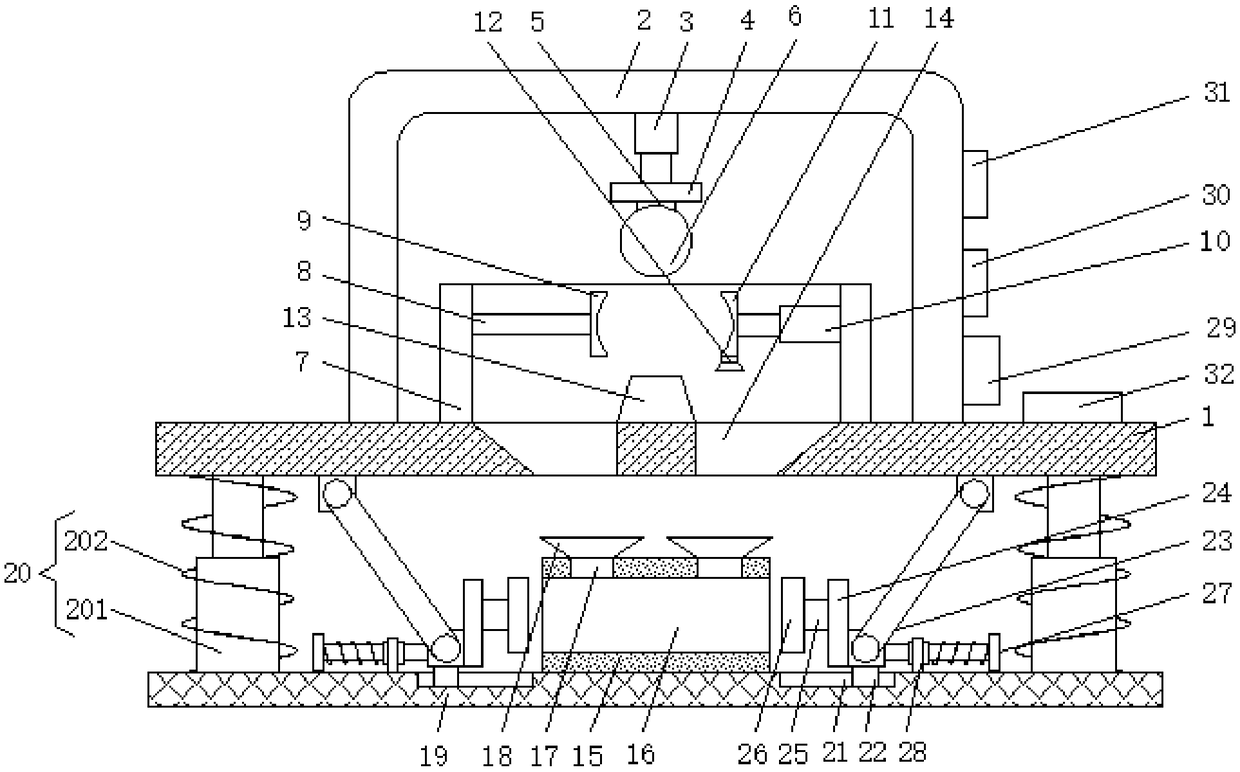

[0035] Embodiment 1, such as Figure 1-6 As shown, a shock-absorbing type polymer material bearing processing lathe for efficiently cleaning debris includes a horizontal plate 1, the upper surface of the horizontal plate 1 is fixedly connected with the lower surface of the U-shaped plate 2, and the inner wall of the U-shaped plate 2 The upper surface of the upper surface is fixedly connected with the upper surface of the first connecting plate 4 through the first electric push rod 3. By setting the first electric push rod 3, the motor 5 and the turning tool 6 can be elongated to cut the workpiece. The U-shaped The right side of plate 2 is provided with first switch 29, the second switch 30 and the 3rd switch 31, and the upper surface of horizontal plate 1 is provided with power supply 32, and the output end of power supply 32 is respectively connected with the first switch 29, the second switch 29 by wire. The input end of the switch 30 and the third switch 31 is electrically ...

Embodiment approach 2

[0036] Embodiment 2, such as Figure 1-6As shown, a shock-absorbing type polymer material bearing processing lathe for efficiently cleaning debris, the left side of the inner wall of the baffle 7 is fixedly connected with the left side of the first splint 9 through the support rod 8, and the baffle 7 is set It is back-shaped, and the opposite surfaces of the first splint 9 and the second splint 11 are provided with anti-slip lines. By setting the baffle plate 7, and the shape of the baffle plate 7 is a back-shaped shape, it can prevent the debris from moving in the horizontal direction when the workpiece is processed. Splash, so that the stability of the workpiece processing process can be guaranteed to a certain extent. By setting the opposite surfaces of the first splint 9 and the second splint 11 with anti-slip lines, it can prevent the workpiece from sliding after being fixed, so that the process of workpiece processing More stable, the right side of the inner wall of the ...

Embodiment approach 3

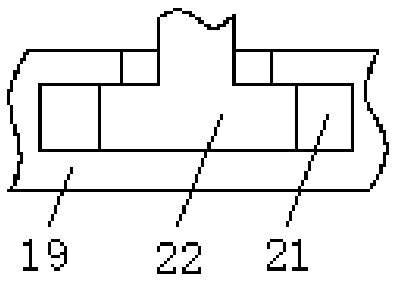

[0037] Embodiment 3, such as Figure 1-6 As shown, a shock-absorbing type polymer material bearing processing lathe for efficiently cleaning debris, the upper surface of the bottom plate 19 is provided with two chute 21, and the two chute 21 are respectively located on the left and right sides of the placement plate 15, The shape of the chute 21 is T-shaped, and the shape of the slide block 22 is T-shaped. By setting the shapes of the slide block 22 and the chute 21 to be T-shaped, the slide block 22 can not shake up and down in the chute 21, thereby It can ensure the stability of the movement of the first connecting block 231, and can make the shock absorption process of the present invention more stable. A slide block 22 is slidably connected in the chute 21, and the upper surface of the slide block 22 is fixedly connected with the lower surface of the rotating device 23. The upper surface of the device 23 is fixedly connected with the lower surface of the horizontal plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com