Integrated molding welding method

A welding method and an integrated technology, applied in welding equipment, auxiliary devices, metal processing, etc., can solve problems such as low welding efficiency, long welding time, and hidden dangers, and achieve the effects of reducing safety hazards, improving work efficiency, and achieving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

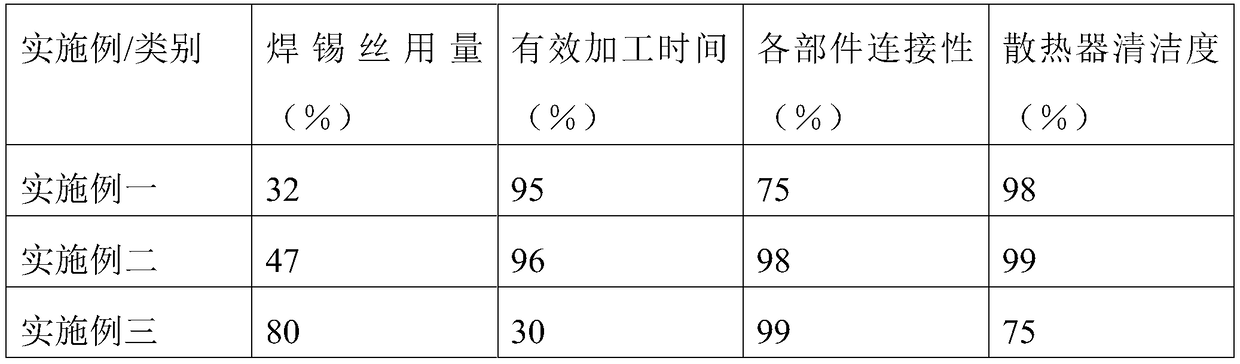

Embodiment 1

[0046] The invention provides an integral molding welding method, comprising the following steps:

[0047] A. Pretreatment: Process the plate fins, auxiliary plates and seals. After the processing is completed, add solder surface at the place where welding is required. The thickness of the solder surface is 0.08cm. Pretreatment is performed on the plate fins, auxiliary plates and seals , so that the area to be welded is added with a solder surface, which can effectively reduce the fixing time during the welding process and improve the welding quality at the same time;

[0048] B. Assembly: Assemble and process the plate fins, auxiliary plates and seals to form a whole radiator. After the assembly is completed, simply fix it to ensure that the parts can be tightly fitted during transportation to prevent damage to the radiator. Vibration occurs during the transfer welding process, which affects the welding quality;

[0049] C. Preheating: The radiator is transported through the...

Embodiment 2

[0055] The invention provides an integral molding welding method, comprising the following steps:

[0056] A. Pretreatment: Process the plate fins, auxiliary plates and seals. After the processing is completed, add a solder surface at the place where welding is required. The thickness of the solder surface is 0.09cm. Pretreatment is performed on the plate fins, auxiliary plates and seals , so that the area to be welded is added with a solder surface, which can effectively reduce the fixing time during the welding process and improve the welding quality at the same time;

[0057] B. Assembly: Assemble and process the plate fins, auxiliary plates and seals to form a whole radiator. After the assembly is completed, simply fix it to ensure that the parts can be tightly fitted during transportation to prevent damage to the radiator. Vibration occurs during the transfer welding process, which affects the welding quality;

[0058] C. Preheating: The radiator is transported through t...

Embodiment 3

[0064] The invention provides an integral molding welding method, comprising the following steps:

[0065] A. Pretreatment: Process the plate fins, auxiliary plates and seals. After the processing is completed, add a solder surface at the place where welding is required. The thickness of the solder surface is 0.1cm. Pretreatment is performed on the plate fins, auxiliary plates and seals , so that the area to be welded is added with a solder surface, which can effectively reduce the fixing time during the welding process and improve the welding quality at the same time;

[0066] B. Assembly: Assemble and process the plate fins, auxiliary plates and seals to form a whole radiator. After the assembly is completed, simply fix it to ensure that the parts can be tightly fitted during transportation to prevent damage to the radiator. Vibration occurs during the transfer welding process, which affects the welding quality;

[0067] C. Preheating: The radiator is transported by the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com