Welding seam halogen-free ferrite stainless steel flux-cored wire and preparation method thereof

A ferrite and stainless steel technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of poor anti-oxidation color performance, decreased durability, and reduced corrosion resistance, so as to achieve no oxidation color in weld formation, The effect of improving process stability and increasing weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

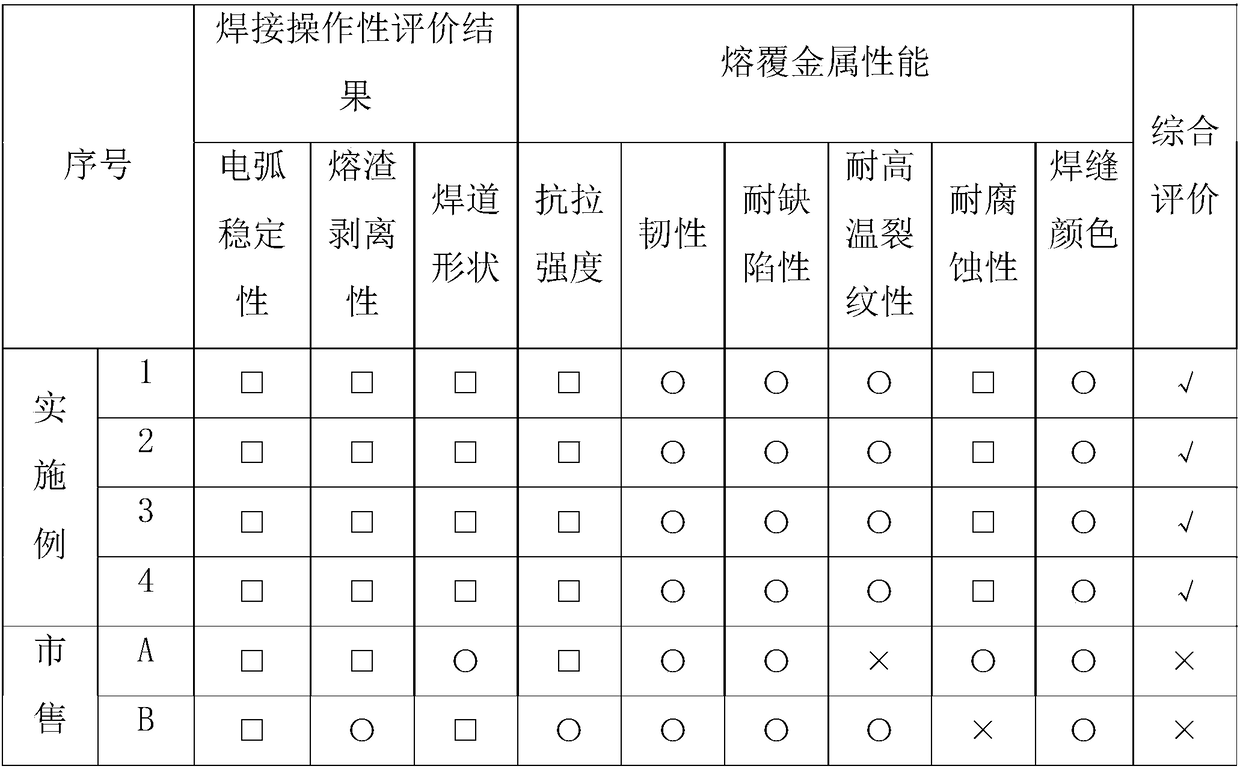

Examples

Embodiment 1

[0031] A non-oxidizing color ferritic stainless steel coated welding wire for welding seam is composed of a welding core and a coating, the coating wraps the welding wire, and an adhesive bonds the coating around the welding core. The components of the coating welding wire are as follows:

[0032] Adhesive composition: It is made up of potassium water glass and sodium water glass mixed in a mass ratio of 1:1; the Baume degree of potassium water glass is 0.44, the modulus is 2.7, the mass percentage of potassium oxide is 14%, of which dioxide The mass percentage of silicon is 28.0%, and the rest is water; the Baume degree of sodium water glass is 0.44 and the modulus is 2.2, of which the mass percentage of silica is 25.7%, the mass percentage of sodium oxide is 12.8%, and the rest are water;

[0033] Wire composition: The mass percentage of each chemical composition is: C 0.04%, Si 0.5%, Co 0.05%, Tc5%, Zr 2%, Mn 1.0%, Cr 15%, Ti 0.3%, Ni 5.5%, S 0.015%, P 0.02%, the rest are ...

Embodiment 2

[0042] A ferritic stainless steel coated welding wire with no oxidation color in the welding seam, which is composed of a welding core and a coating, the coating wraps the welding wire, and the adhesive sticks the coating around the welding core. The components of the coating welding wire are as follows:

[0043] Adhesive ingredients: potassium water glass and sodium water glass are mixed at a mass ratio of 2:1; the potassium water glass has a Baume degree of 45, a modulus of 2.8, and a mass percentage of potassium oxide of 15%, of which The mass percentage content of silicon is 30%, and the rest is water; the Baume degree of sodium silicate glass is 0.45, and the modulus is 2.4, wherein the mass percentage content of silicon dioxide is 25.9%, the mass percentage content of sodium oxide is 12.9%, and the rest is water;

[0044] Welding wire composition: The mass percentage of each chemical composition is: C 0.03%, Si0.8%, Co 0.08%, Tc6%, Zr 4%, Mn 0.8%, Cr 18%, Ti 0.25%, Ni 6....

Embodiment 3

[0053] A ferritic stainless steel coated welding wire with no oxidation color in the welding seam, which is composed of a welding core and a coating, the coating wraps the welding wire, and the adhesive sticks the coating around the welding core. The components of the coating welding wire are as follows:

[0054] Adhesive ingredients: potassium water glass and sodium water glass are mixed at a mass ratio of 3:1; the potassium water glass has a Baume degree of 0.46, a modulus of 2.9, and a mass percentage of potassium oxide of 17%. The mass percentage content of silicon is 31.0%, and the rest is water; the Baume degree of sodium silicate glass is 0.46, and the modulus is 2.5, wherein the mass percentage content of silicon dioxide is 26.0%, the mass percentage content of sodium oxide is 13%, and the rest is water;

[0055] Welding wire composition: The mass percentage of each chemical composition is: C 0.02%, Si1%, Co 0.1%, Tc 8%, Zr2-6%, Mn 1.0%, Cr 20%, Ti 0.3%, Ni 6.5%, S 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com