Integral multi-edge contour knife processing method

A processing method and integral technology, applied in metal processing equipment, workpieces, milling cutters, etc., can solve problems such as insufficient welding strength and precision, affecting cutting quality and service life, and inability to adapt to the development trend of high-precision and long-life tools. , to achieve the best processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

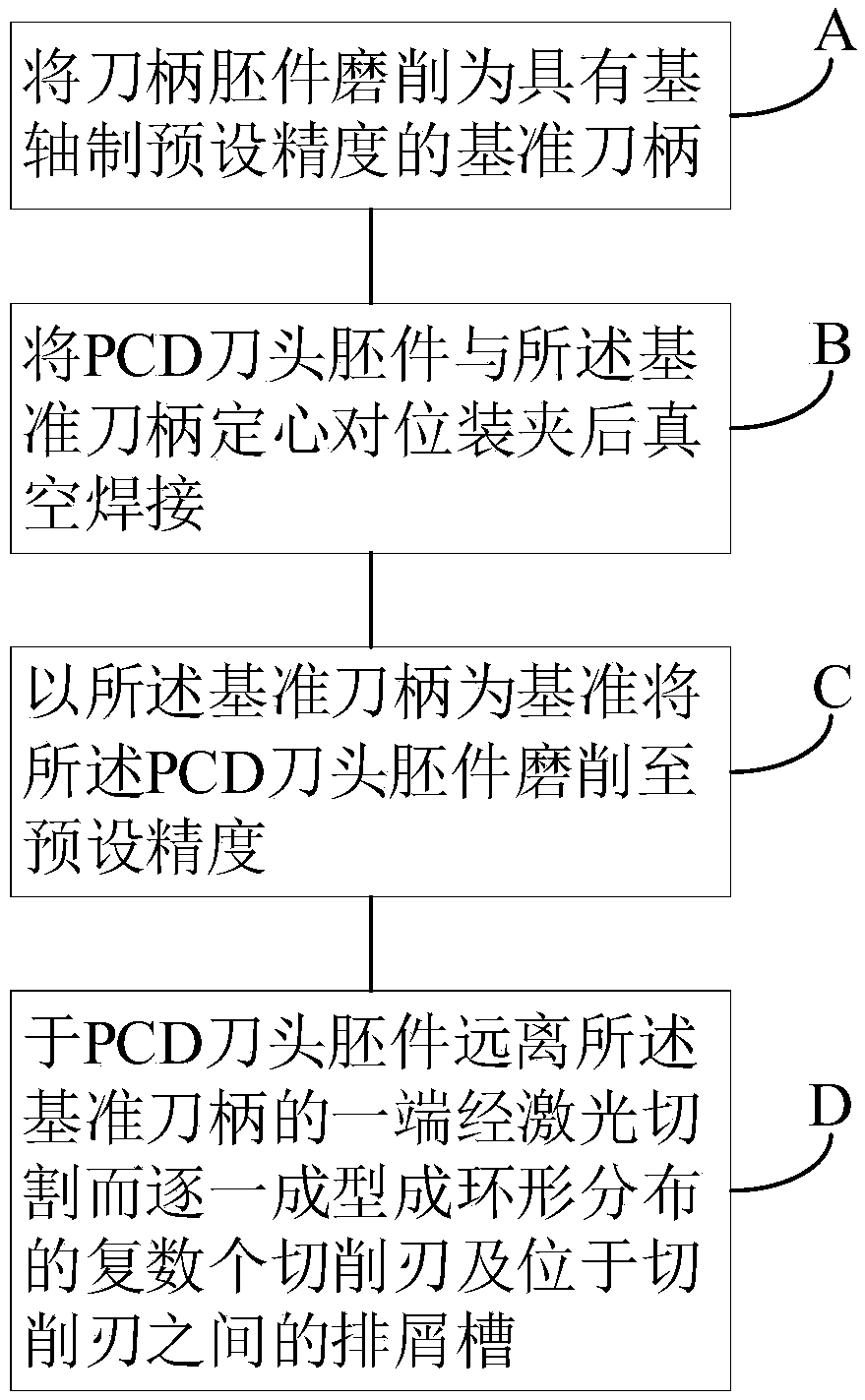

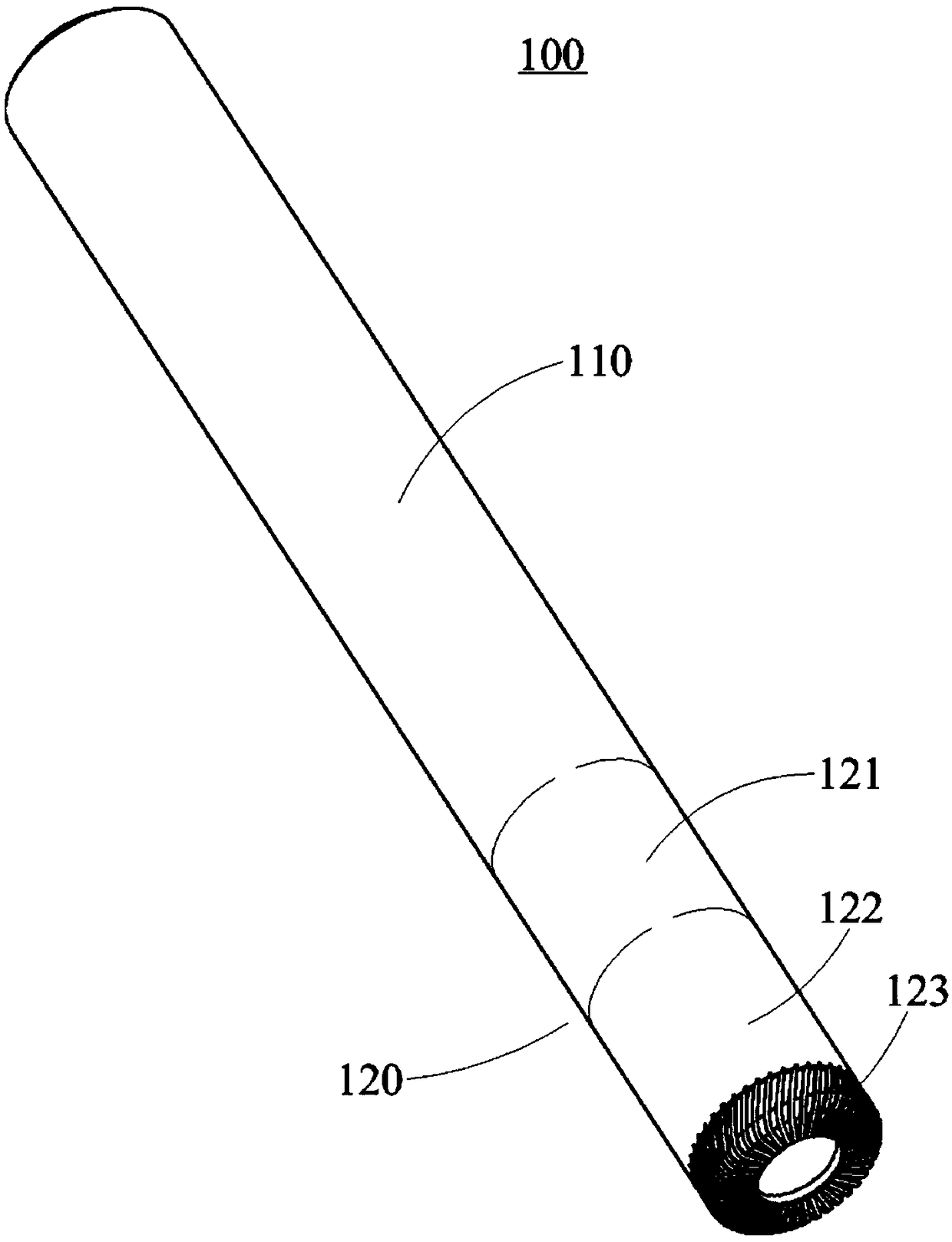

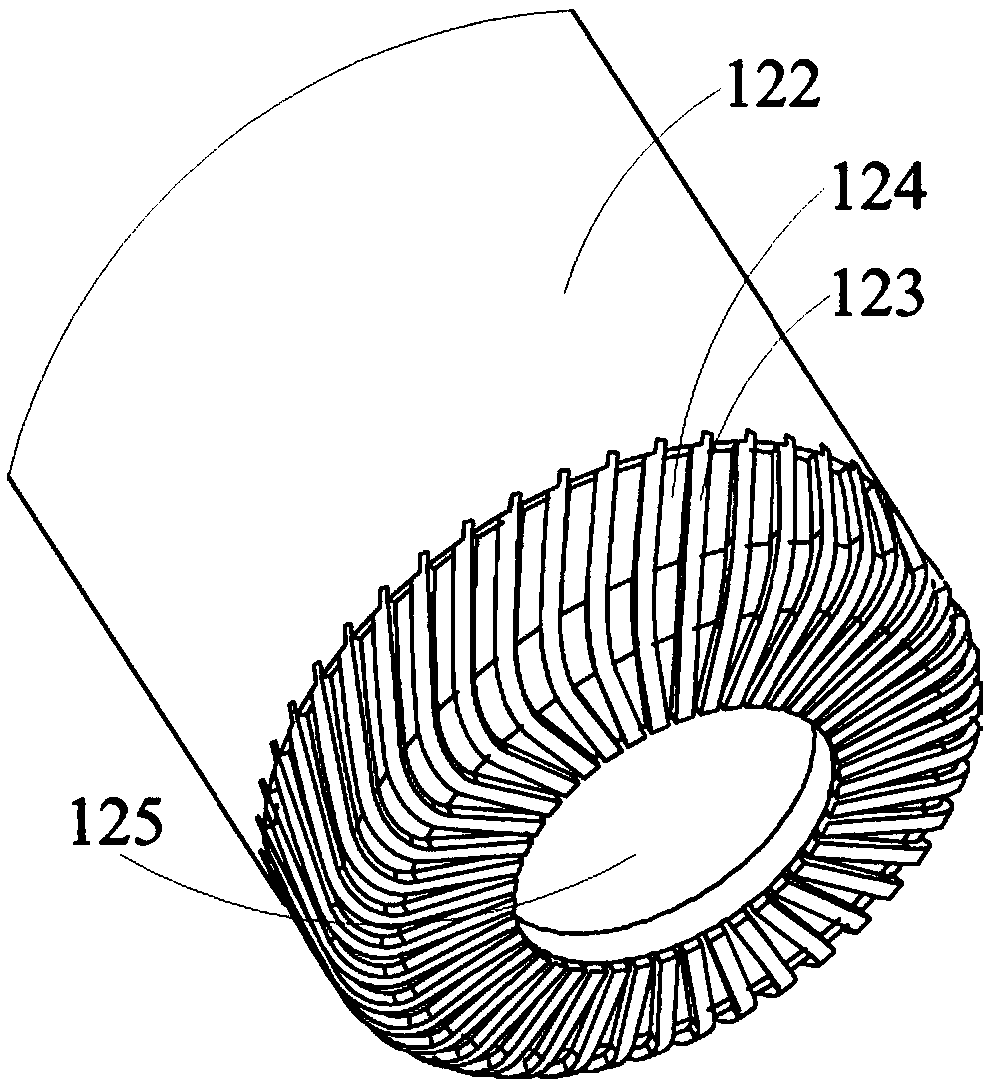

[0034] Please refer to Figure 1~4 This embodiment discloses a processing method for an integral multi-blade contour cutter, which is used for processing the integral multi-blade contour cutter 100. The processing method includes the following steps:

[0035] Step A: Grinding the tool handle blank into a reference tool handle 110 with a preset accuracy of the base axis. Exemplarily, the tool holder blank is a cylindrical blank with basic dimensions, which is ground to obtain the required circumferential accuracy. Exemplarily, the shank blank may be cut from a cylindrical bar stock.

[0036] After grinding, the tool handle blank obtains the preset precision of the base shaft system, and the product is the reference tool handle 110 . The so-called preset accuracy of the base axis system refers to the preset accuracy under the base axis system. In other words, the reference toolholder 110 is a reference axis, the basic deviation of which is zero. In subsequent processing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com