Winding forming method of variable-taper heat-proof layer

A technology of winding forming and heat-proof layer, applied in the field of winding and forming of variable-taper heat-proof layer, can solve the problems of increasing production process, easy shortage of materials, and high mold cost, achieving high continuous productivity and production efficiency, and good application prospects. , the effect of excellent molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

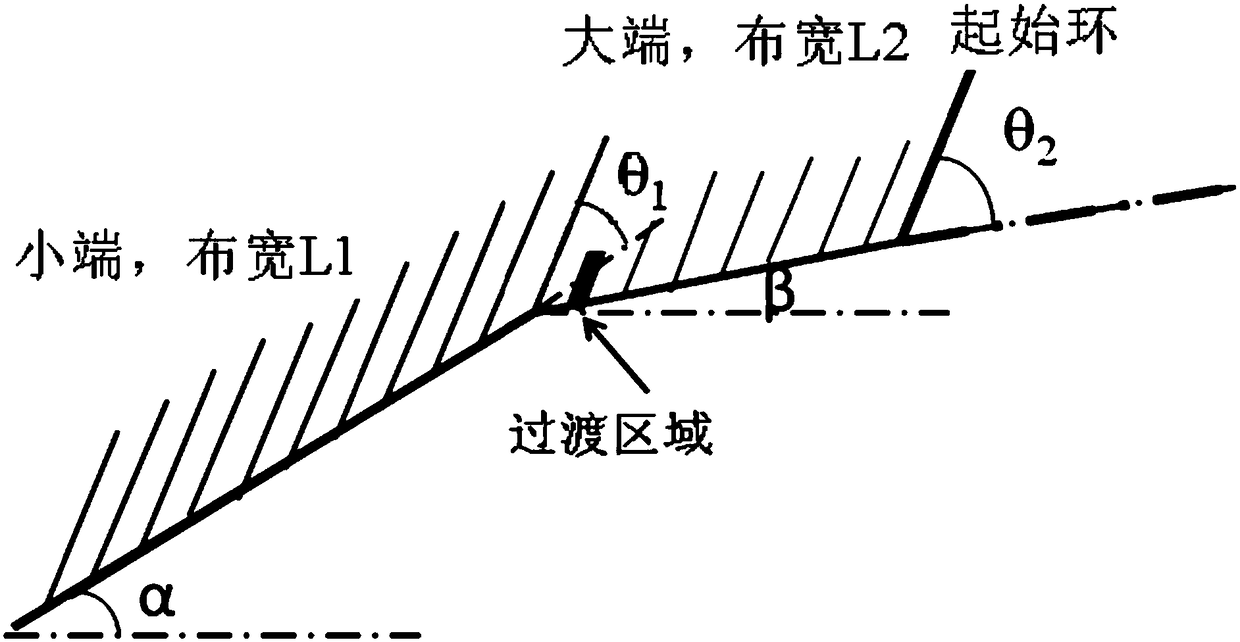

[0039] Such as figure 1 with figure 2 As shown, the product is a double cone angle rotary body structure, the total length of the product is 400mm, and the diameter of the small end is length is The cone angle is The big end taper angle is The thickness requirement is 20mm. The material adopts high silicon oxygen / phenolic material system. The mold design cone angles are 16° and 4° respectively. Within the scope of the product area, the diameter of the small end of the mold is 399.8mm, and the diameter of the mold at the corner is 400+200×tan16° ×2=514.70mm, the diameter of the big end of the mold is 514.70+200×tan4°×2=542.67mm; considering that the airflow at the small end is more serious, the winding angle of the small end is designed to be 15°, and the winding angle of the big end is 15+16- 4=27°, the theoretical fabric width of the small end is 20 / sin15°≈80mm, the theoretical fabric width of the big end is 20 / sin27°≈44mm, considering the machining allowance and tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com