Method for separating and enriching lithium

An enrichment and separation device technology, applied in semi-permeable membrane separation, chemical instruments and methods, lithium compounds, etc., can solve problems such as low lithium ion yield, improve enrichment efficiency, improve rationality, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

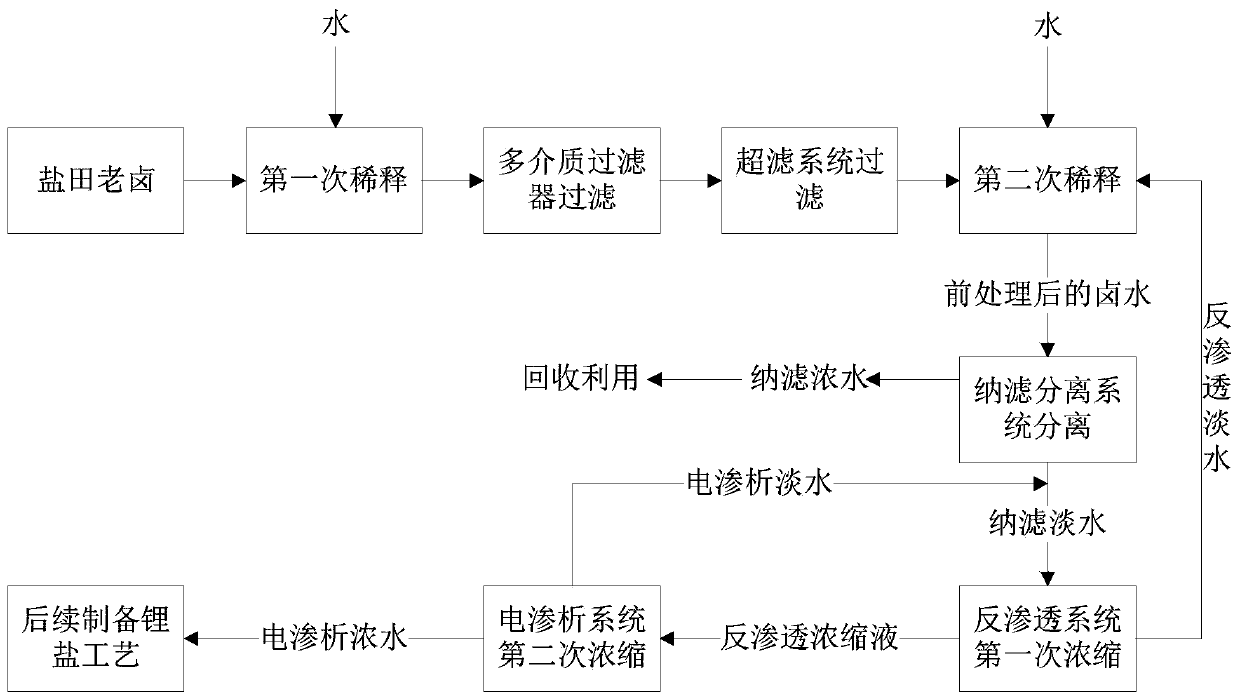

[0030] This embodiment provides a method for separating and enriching lithium, combiningfigure 1 Shown is the flow process of this embodiment, the method of this embodiment includes the following steps:

[0031] Pre-treatment: Dilute the above-mentioned Yantian old brine for the first time, and the dilution factor is 2.5 times. The first diluted Yantian old brine is first sent to a multimedia filter to remove some mechanical impurities such as silt, and then sent to an organic supernatant. Filtration system for complete removal of impurities, and then the second dilution, the dilution factor of the second dilution is 7.5 times, to obtain the pre-treated brine.

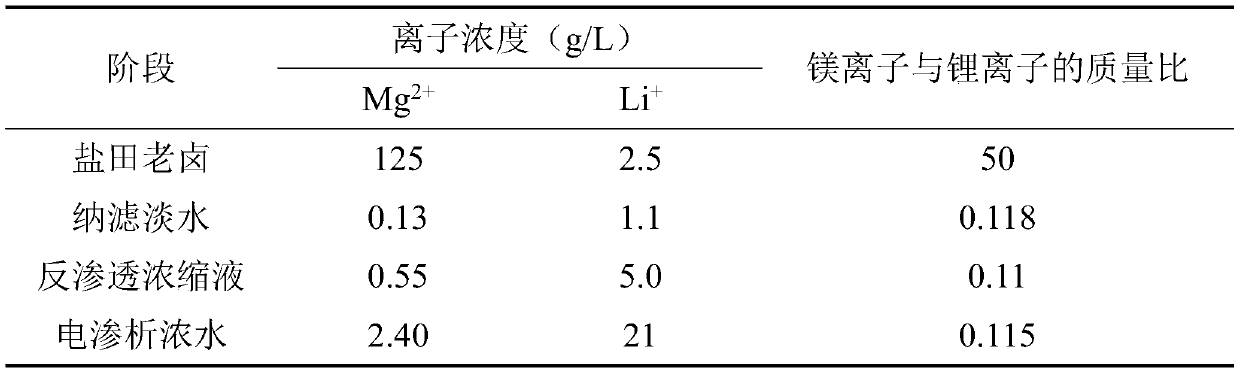

[0032] Separation: The pretreated brine is separated by a nanofiltration separation system to obtain nanofiltration fresh water and nanofiltration concentrated water. The concentration of lithium ions in the nanofiltration fresh water is 1.1g / L, and the concentration of magnesium ions is reduced to 0.13g / L , the mass r...

Embodiment 2

[0042] The present embodiment provides a method for separating and enriching lithium, comprising the following steps:

[0043] Pre-treatment: Dilute the above-mentioned Yantian old brine for the first time, and the dilution factor is 2.5 times. The first diluted Yantian old brine is first sent to a multimedia filter to remove some mechanical impurities such as silt, and then sent to an organic supernatant. Filtration system for complete removal of impurities, and then the second dilution, the dilution factor of the second dilution is 7.5 times, to obtain the pre-treated brine.

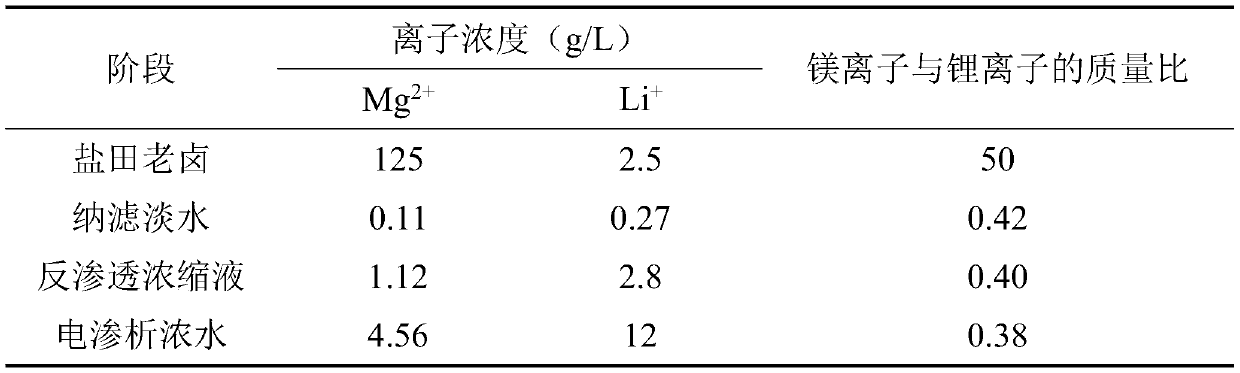

[0044] Separation: The pretreated brine is separated by a nanofiltration separation system to obtain nanofiltration fresh water and nanofiltration concentrated water, in which the concentration of lithium ions in the nanofiltration fresh water is 0.27g / L, and the concentration of magnesium ions is reduced to 0.11g / L , the mass ratio of magnesium ions to lithium ions is 0.42:1. specifically is:

[004...

Embodiment 3

[0054] The present embodiment provides a method for separating and enriching lithium, comprising the following steps:

[0055] Pre-treatment: Dilute the above-mentioned Yantian old brine for the first time, and the dilution factor is 2.5 times. The first diluted Yantian old brine is first sent to a multimedia filter to remove some mechanical impurities such as silt, and then sent to an organic supernatant. Filtration system for complete removal of impurities, and then the second dilution, the dilution factor of the second dilution is 7.5 times, to obtain the pre-treated brine.

[0056] Separation: The pretreated brine is separated through a nanofiltration separation system to obtain nanofiltration fresh water and nanofiltration concentrated water. The concentration of lithium ions in the nanofiltration fresh water is 0.80g / L, and the concentration of magnesium ions is reduced to 0.29g / L , the mass ratio of magnesium ions to lithium ions is 0.36:1. specifically is:

[0057] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com