Environmentally-friendly and bacteriostatic waterborne ink and preparation method thereof

A water-based ink, environmentally friendly technology, used in inks, household appliances, applications, etc., can solve the problems of reduced product viscosity, no bacteriostatic and antiseptic effect, no market competitiveness, etc. Bacteria and antiseptic effect, the effect of large market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a technical solution: an environmentally friendly and antibacterial water-based ink, comprising the following components by weight: 37 parts of water-soluble acrylic resin, 16 parts of organic pigment, 11 parts of ethanol, 16 parts of deionized water, and 0.4 part of antibacterial agent , 1 part of nonionic surfactant, 2.2 parts of fillers and additives.

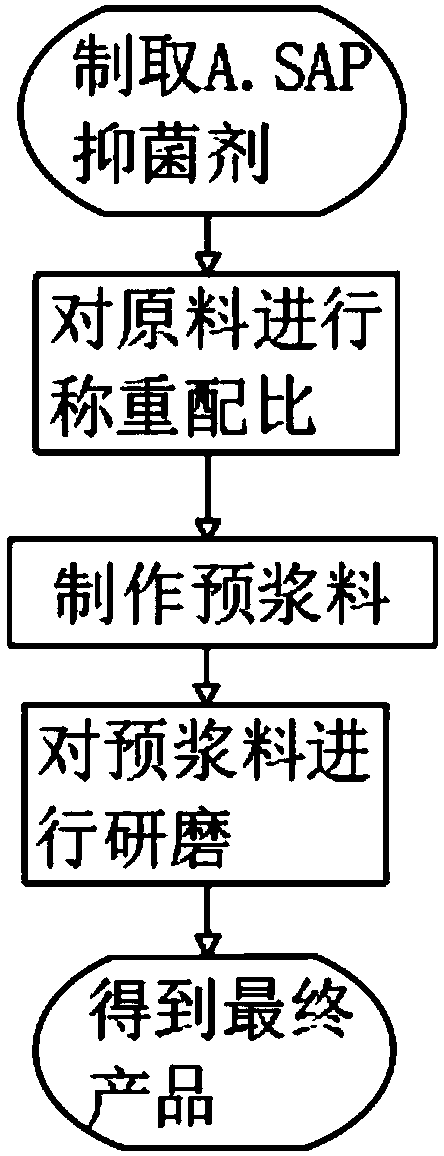

[0026] A kind of water-based ink of environmental protection antibacterial and preparation method thereof, comprises the following steps:

[0027] S1: Prepare the A.SAP bacteriostatic agent, purify the A.SAP bacteriostatic agent, and store the purified A.SAP bacteriostatic agent;

[0028] S2: Weigh all the required raw materials and take them according to a certain ratio, including 37 parts of water-soluble acrylic resin, 16 parts of organic pigment, 11 parts of ethanol, 16 parts of deionized water, 0.4 parts of antibacterial agent, and non-ionic surface 1 part active agent, 2.2 parts fillers a...

Embodiment 2

[0038] The invention provides a technical solution: an environmentally friendly and antibacterial water-based ink, comprising the following components by weight: 70 parts of water-soluble acrylic resin, 22 parts of organic pigment, 18 parts of ethanol, 30 parts of deionized water, and 0.6 part of antibacterial agent , 2.6 parts of nonionic surfactant, 3 parts of filler and auxiliary agent.

[0039] A kind of water-based ink of environmental protection antibacterial and preparation method thereof, comprises the following steps:

[0040] S1: Prepare the A.SAP bacteriostatic agent, purify the A.SAP bacteriostatic agent, and store the purified A.SAP bacteriostatic agent;

[0041] S2: Weigh all the required raw materials and take them according to a certain ratio, including 70 parts of water-soluble acrylic resin, 22 parts of organic pigments, 18 parts of ethanol, 30 parts of deionized water, 0.6 parts of antibacterial agent, and non-ionic surface 2.6 parts of active agent, 3 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com