Method for rapidly determining antibiotic resistance of Escherichia coli in biofilm

A technology of antibiotic resistance and biofilm, which is applied in the direction of biochemical equipment and methods, microbial measurement/inspection, etc., to achieve the effect of easy repeatability, less supporting equipment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

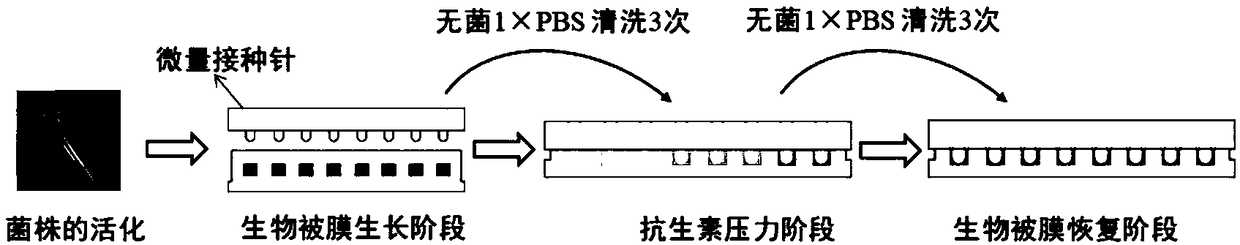

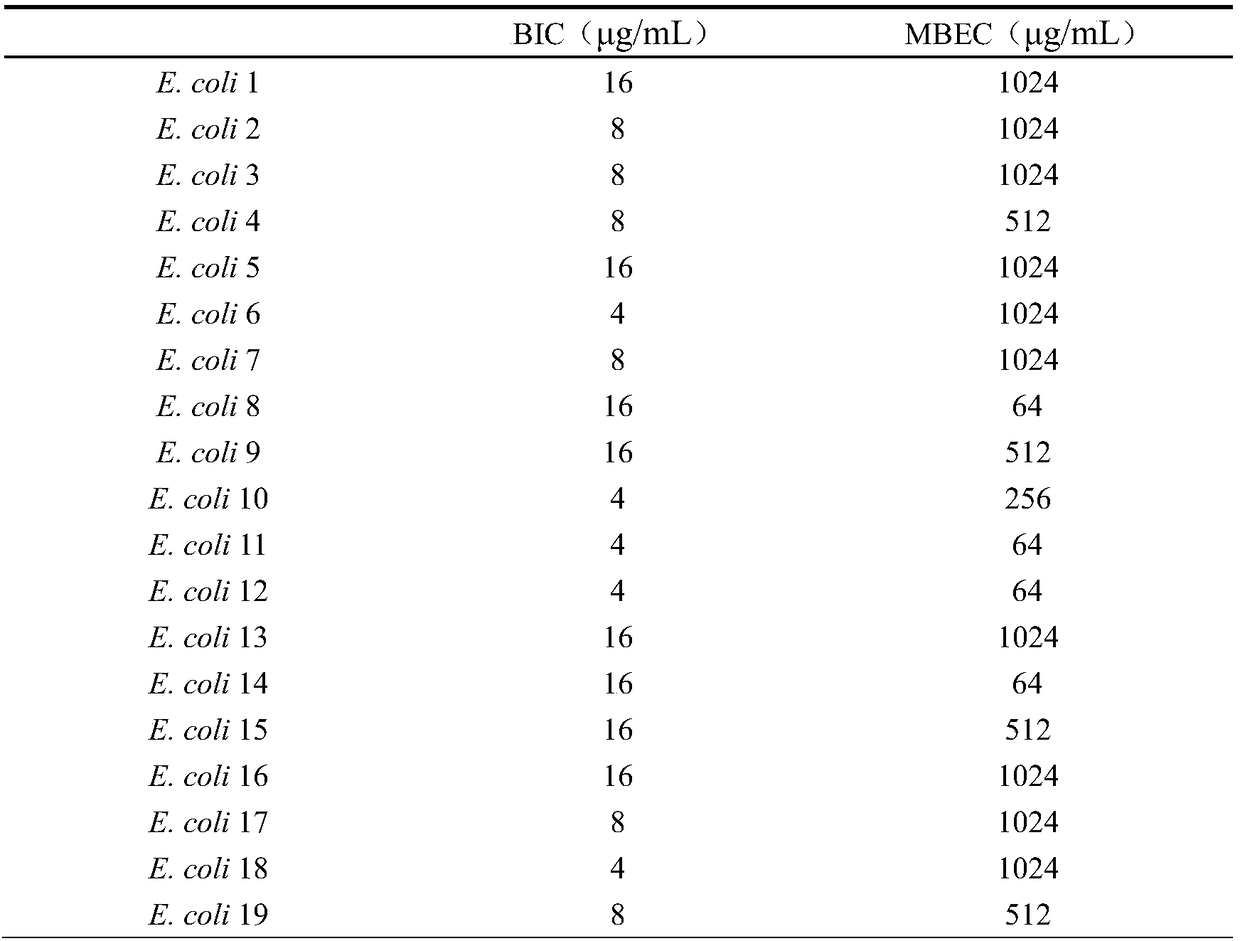

[0032] A method for constructing Escherichia coli in a biofilm resistant to polymyxins, the experimental flow chart is as follows figure 1 As shown, the order is: the activation of the strain; the biofilm growth stage; the antibiotic stress stage; the biofilm recovery stage. The steps of the method include:

[0033] (1) Biofilm growth stage

[0034] Take out the Escherichia coli stored in the glycerol tube from the -80°C refrigerator, place it on the ice box, and thaw it for about 5 minutes. In the aseptic operating table, use a sterile inoculation loop to draw a line on the LB agar plate, place it in a constant temperature incubator, and incubate at 37°C for 16-18h. Pick a single colony and put it in 9mL LB broth, place it in a shaker at 37°C and 200rpm and culture it for 16-18h.

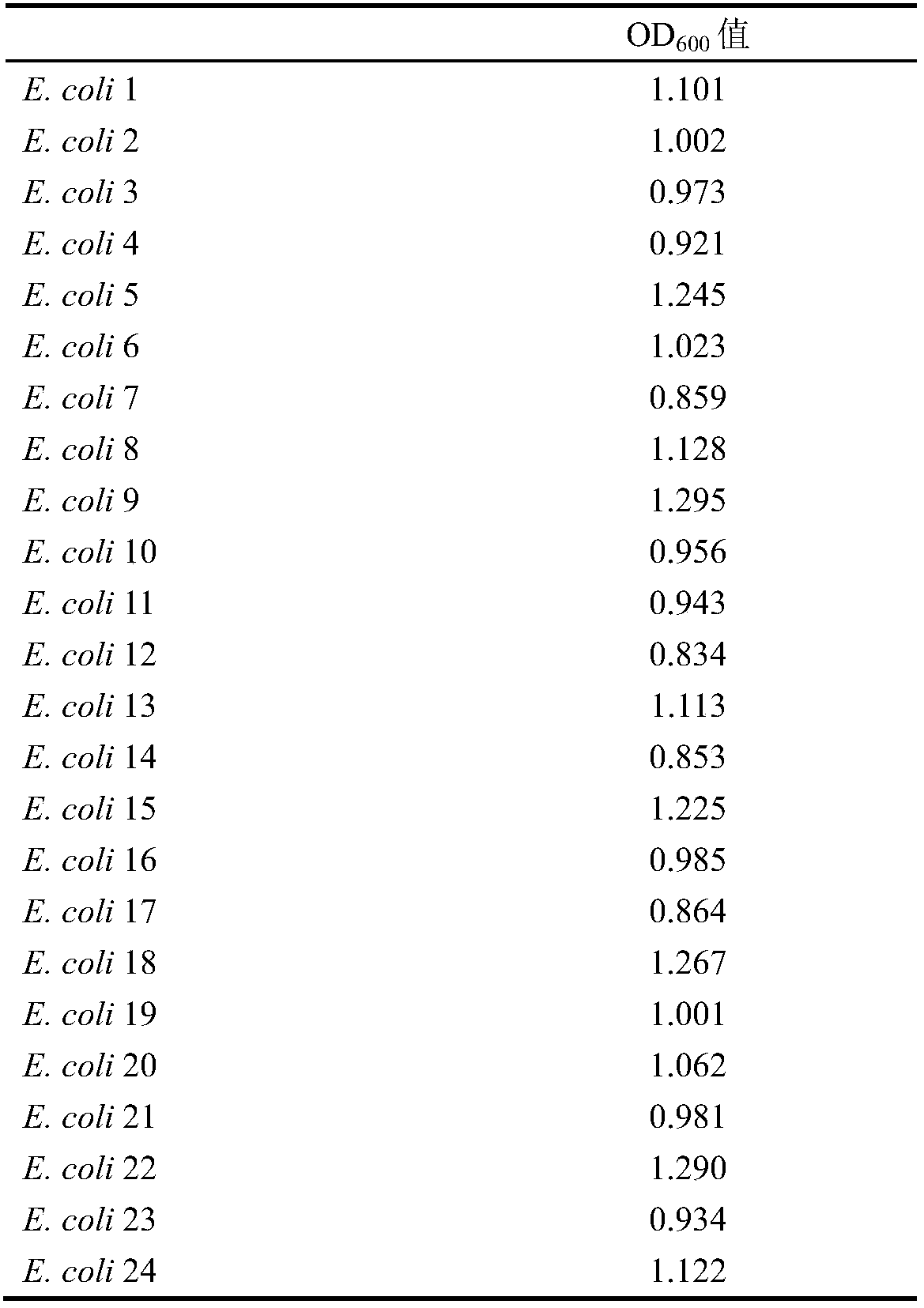

[0035] Centrifuge the cultured thalline at 3000rpm, 10min, and 25°C, remove the supernatant (the supernatant is the centrifuged medium), and adjust the concentration of the bacterial solution wi...

Embodiment 2

[0056] Embodiment 2 plate coating method determines Escherichia coli optimal culture temperature

[0057] According to the above-mentioned method of activating and diluting, the OD value of the thalline was adjusted to the bacterium solution of OD600 value=0.5 McFarland, (the bacterial concentration was about 1×10 9 cfu / mL) for the cultivation of biofilms. Take 10 μL of the above-mentioned E. coli culture solution and add it to a 24-well plate containing 990 μL fresh LB (3% NaCL) medium, and use the fresh LB well plate not inoculated with the bacteria solution as a blank control, and make 3 parallels for each strain. Select four different temperatures (15°C, 25°C, 37°C and 45°C) and culture them statically for 24 hours to measure the amount of biofilm formation. The 24-well plate was sealed with plastic wrap to prevent moisture from evaporating.

[0058] After the cultivation, the bacterial solution in the well plate was first discarded, and the non-adhered bacteria were was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com