Metal V-shaped grating Fano resonance structure with adjustable tip spacing

A resonant structure and adjustable technology, applied in optics, optical components, and material analysis through optical means, can solve problems such as difficulty in ensuring target molecules, decreased sensitivity, limited range, etc., to achieve precise transfer and inversion, surface integrity, less susceptible to contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

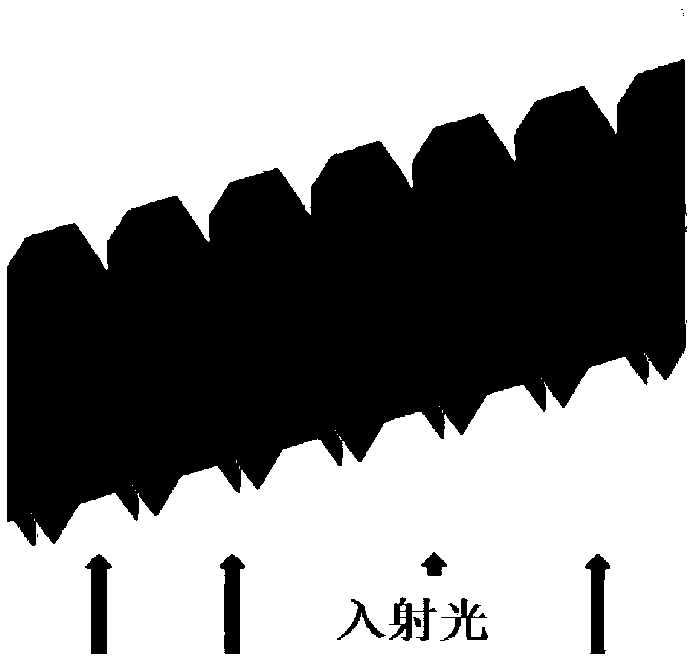

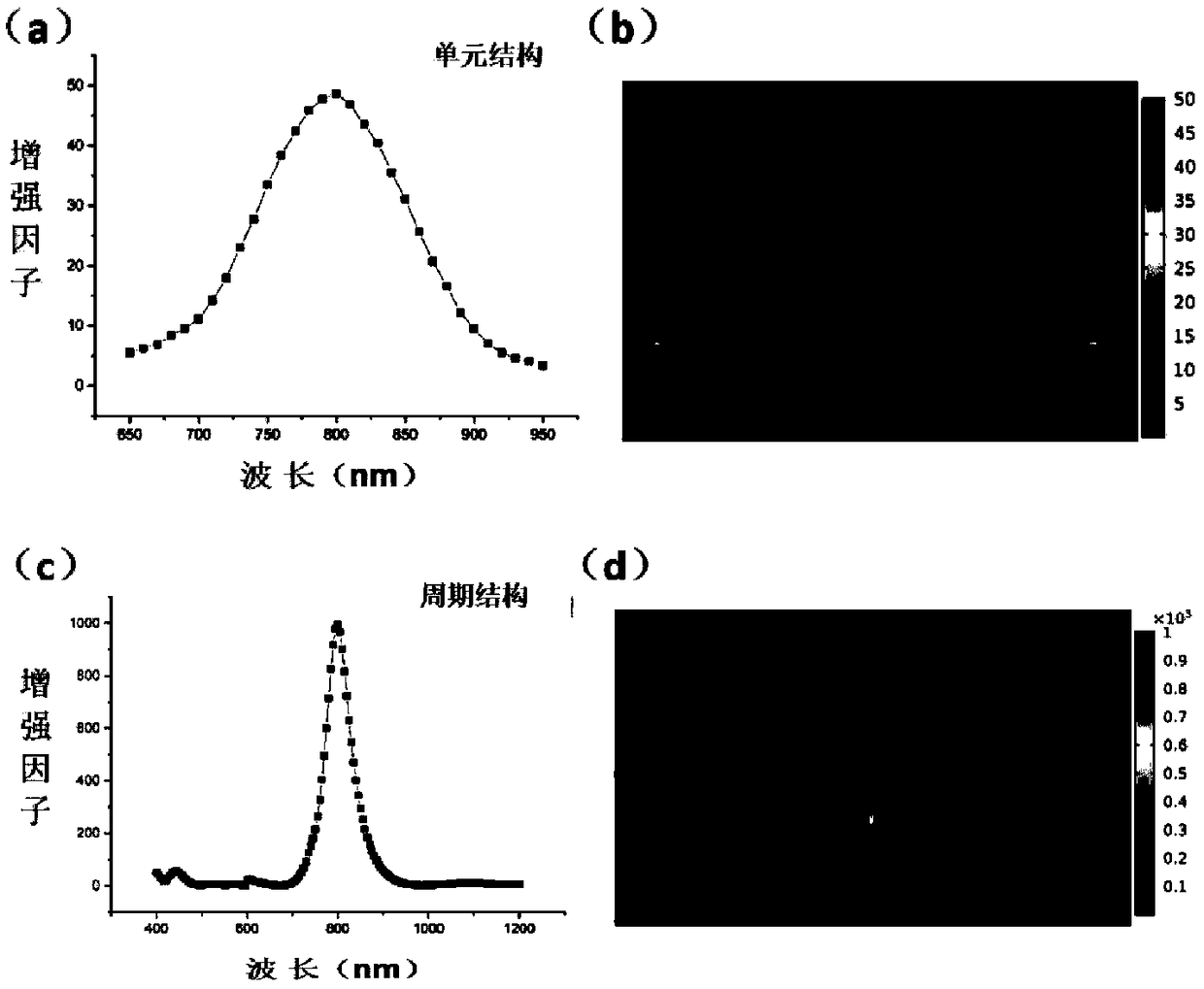

[0019] Such as figure 1 , the metal plasmon Fano resonance structure with adjustable tip spacing of the present invention is sequentially formed on the metal film on the substrate, the optically transparent elastic medium substrate, the metal film is a gold film or silver film, and the optically transparent medium film The material is Nolan glue or epoxy resin. Preferably, the height of the metal film is 220 nm, the thickness is 80 nm, and the period of the grating is 745 nm, so that the grating excites the surface plasmon resonance wave at a wavelength of 800 nm. In addition, the slit pitch of the unit structure is 10 nm.

[0020] Correspondingly, as Figure 4 , the method for preparing the metal plasmon resonance structure includes the following steps:

[0021] (S1) A 35-nm-thick layer of SiO was deposited using chemical vapor deposition (PECVD) on the top silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com