Asymmetric van der Waals heterojunction device, preparation method and use thereof

A heterojunction, asymmetric technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., to achieve the effect of high responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

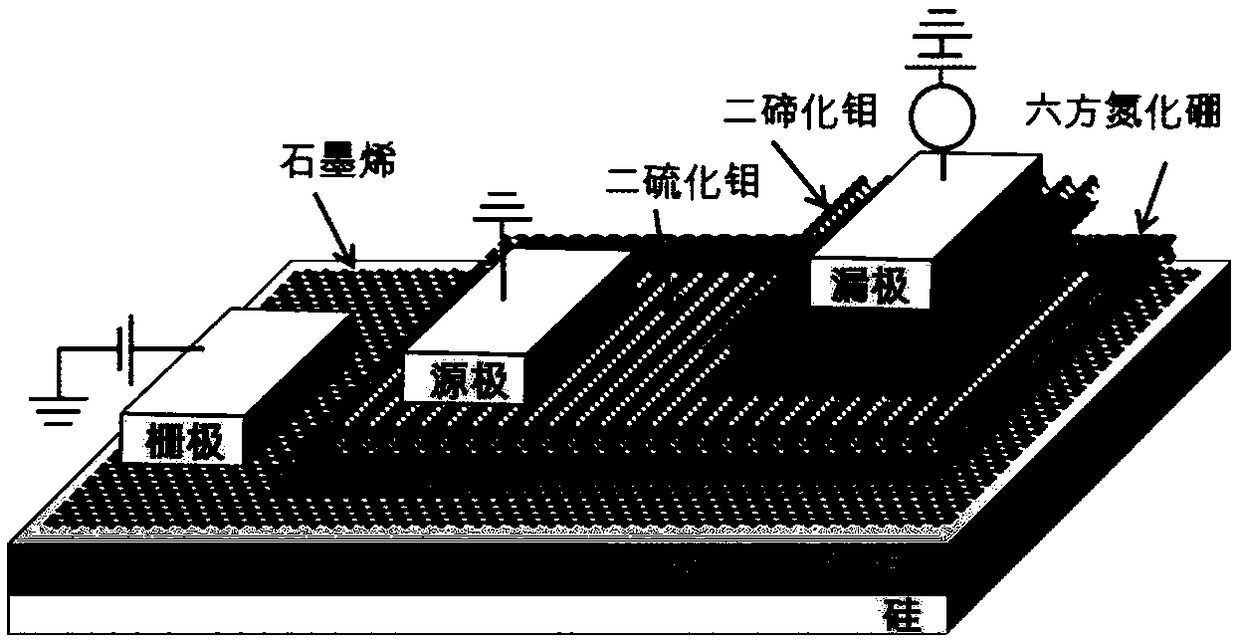

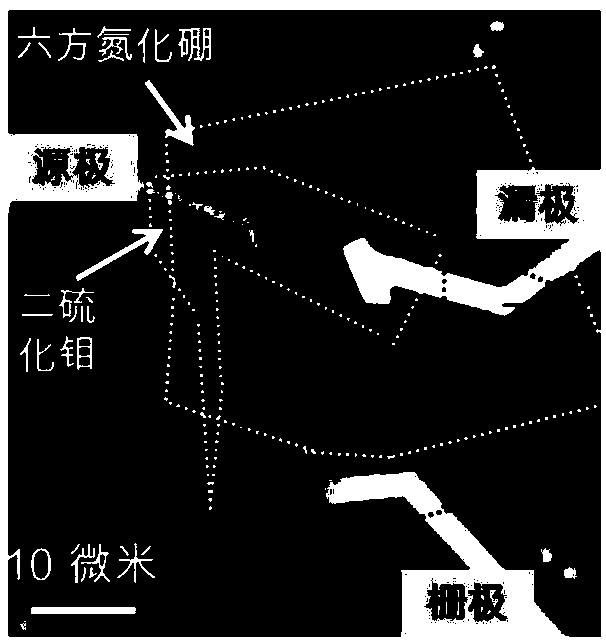

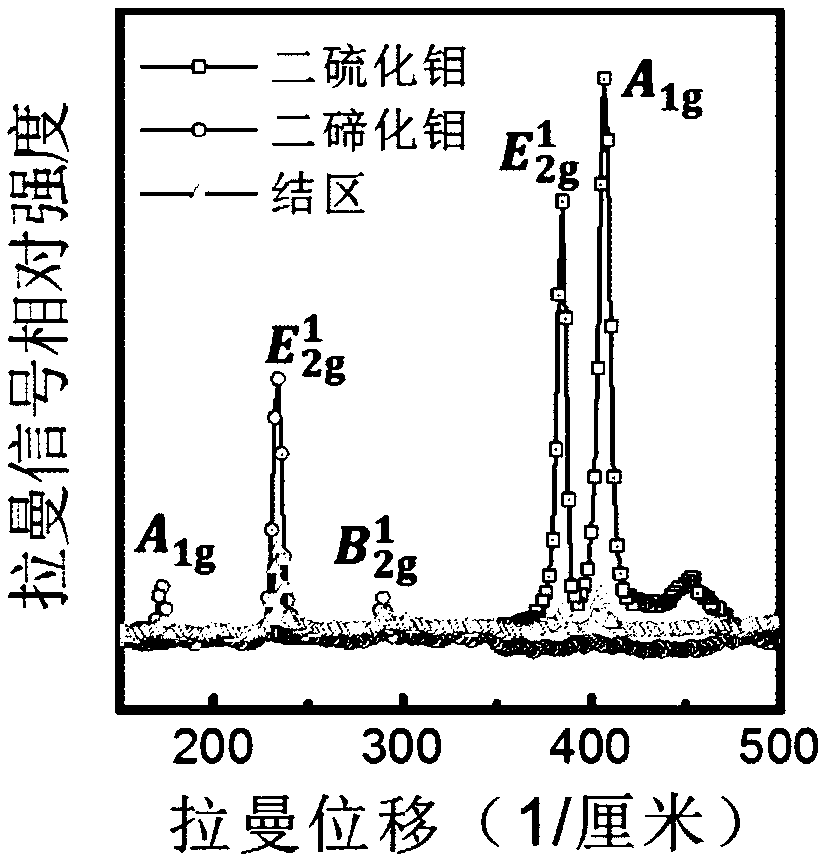

[0041]Fabrication of Asymmetric Van der Waals Heterojunction Devices.

[0042] (1) Graphene nanosheets, hexagonal boron nitride nanosheets, molybdenum disulfide nanosheets, and molybdenum ditelluride nanosheets were all prepared by pasting corresponding bulk materials repeatedly with scotch tape. With the aid of optical microscopy, single-layer graphene nanosheets on scotch tape were placed directly on silicon substrates with 300 nm thick silica; hexagonal boron nitride nanosheets with a suitable thickness , molybdenum disulfide nanosheets and molybdenum ditelluride nanosheets were respectively transferred to a PPC (polymethylethylene carbonate) plastic support film with a thickness of about 300 nanometers. The thickness and area of the corresponding nanosheets were selected by optical microscopy and atomic force microscopy. The thicknesses of the hexagonal boron nitride nanosheets, molybdenum disulfide nanosheets and molybdenum ditelluride nanosheets in Example 1 are 13.8 ...

Embodiment 2

[0055] Fabrication of Asymmetric Van der Waals Heterojunction Devices:

[0056] (1) Graphene nanosheets, hexagonal boron nitride nanosheets, molybdenum disulfide nanosheets, and molybdenum ditelluride nanosheets were all prepared by pasting corresponding bulk materials repeatedly with scotch tape. With the aid of optical microscopy, single-layer graphene nanosheets on scotch tape were placed directly on silicon substrates with 300 nm thick silica; hexagonal boron nitride nanosheets with a suitable thickness , molybdenum disulfide nanosheets and molybdenum ditelluride nanosheets were respectively transferred to a PPC (polymethylethylene carbonate) plastic support film with a thickness of about 300 nanometers. The thickness and area of the corresponding nanosheets were selected by optical microscopy and atomic force microscopy. The thicknesses of the hexagonal boron nitride nanosheets, molybdenum disulfide nanosheets, and molybdenum ditelluride nanosheets in Experimental Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com