Amorphous oxide thin film for thin film transistor channel layer and manufacturing method thereof

A technology of amorphous oxide and thin film transistors, which is applied in the direction of transistors, coatings, metal material coating processes, etc., can solve the problems of high price, difficult mining, accelerated In consumption, etc., to reduce oxygen vacancies, suppress electron concentration, The effect of reducing the off-state current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] 1) SnO with a purity of 99.99% 2 , SiO 2 and ZnO powder as raw materials, weighed according to the atomic ratio Si:Zn:Sn=0.06:1:1, and weighed SiO 2 0.3605 g, ZnO 8.139 g, SnO 2 15.07 g, the weighed powder was poured into a ball mill jar equipped with agate balls and ethanol, and ball milled on a ball mill for 48 hours to make the powder fine and evenly mixed. Then the raw materials are separated, dried at 80°C for 24 hours, added with a binder, ground, and pressed into a disc-shaped embryo body with a diameter of about 3 cm and a thickness of 3 mm. Put the formed green body into the sintering furnace and sinter at 1200 °C for 12 hours to obtain the required ceramic target.

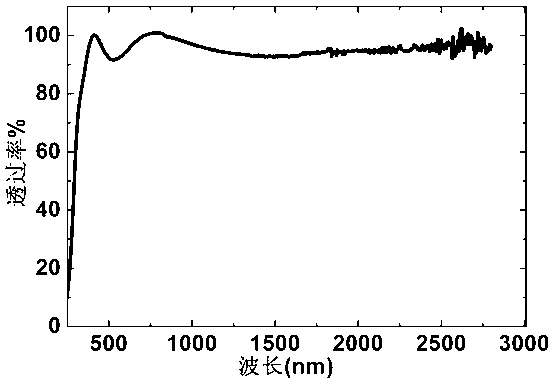

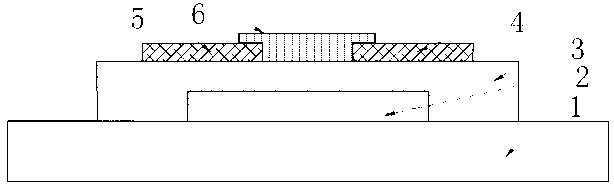

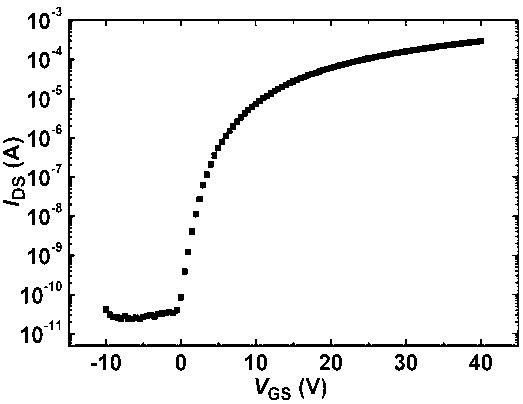

[0025] 2) Using the pulsed laser deposition method, using the ceramic target in step 1) as the target, a layer of amorphous oxide film is deposited on the cleaned substrate. The deposition conditions are: the distance between the glass substrate and the target is 55 mm , the vacuum of the gro...

example 2

[0030] 1) SnO with a purity of 99.99% 2 , SiO 2 and ZnO powder as raw materials, weighed according to the atomic ratio Si:Zn:Sn=0.14:1:1, and weighed SiO 20.8413 g, ZnO 8.139 g, SnO 2 15.07 g, the weighed powder was poured into a ball mill jar equipped with agate balls and ethanol, and ball milled on a ball mill for 48 hours to make the powder fine and evenly mixed. Then the raw materials were separated, dried at 80°C for 24 hours, added with a binder, ground, and pressed into a disc shape with a diameter of about 3 cm and a thickness of 3 mm. Put the formed green body into the sintering furnace and sinter at 1200 °C for 12 hours to obtain the required ceramic target.

[0031] 2) Using the pulsed laser deposition method, using the ceramic target in step 1) as the target, a layer of amorphous oxide film is deposited on the cleaned substrate. The deposition conditions are: the distance between the glass substrate and the target is 55 mm , the vacuum of the growth chamber wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com