N-type high-efficiency crystalline silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of low doping efficiency and carrier mobility of amorphous silicon films, achieve the effects of improving electrical characteristics, low equipment cost, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

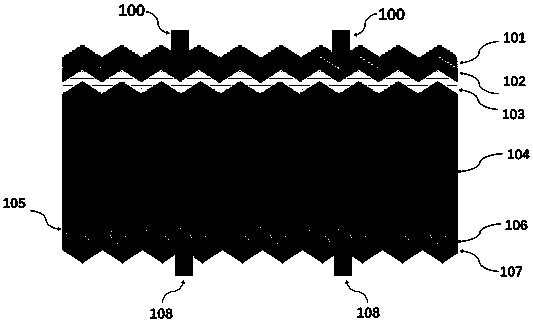

[0025] Embodiment: the present invention provides a kind of N-type high-efficiency crystalline silicon solar cell and preparation method thereof, such as figure 1 As shown, its structure includes a front surface metal electrode 100, a front surface ITO film 101, a boron-doped polycrystalline silicon germanium film (emitter) 102, a front surface intrinsic amorphous silicon film 103, an N-type crystalline silicon 104, and a back surface intrinsic An amorphous silicon film 105 , a phosphorus-doped polycrystalline silicon germanium film (back field) 106 , an ITO film 107 on the back surface, and a metal electrode 108 on the back surface.

[0026] The specific steps of the preparation method of the present invention are as follows:

[0027] Firstly, conventional texturing is performed on N-type crystalline silicon, and textured structures appear on both the front surface and the back surface of the crystalline silicon substrate after texturing. Next, perform standard RCA cleaning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com