Robot end actuator used for picking clustered tomatoes

An end effector and robot technology, applied in the field of automation, can solve the problems of prolonging the decision-making process and path planning time of the robot, high cost of manual harvesting, and reducing the efficiency of the robot picking operation, so as to shorten the decision-making process and path planning time, improve the The success rate of fruit stem separation and the effect of improving the efficiency of picking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

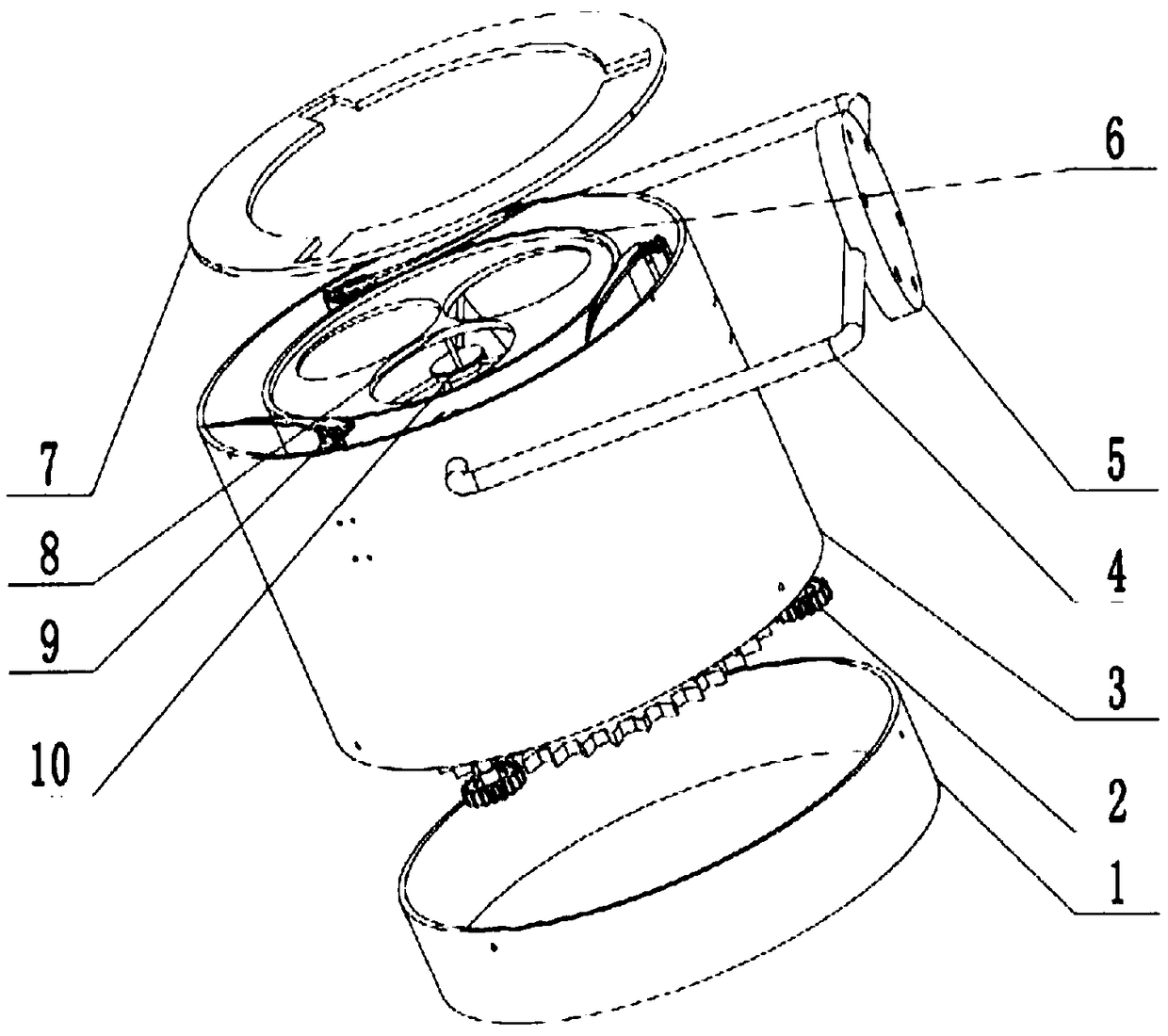

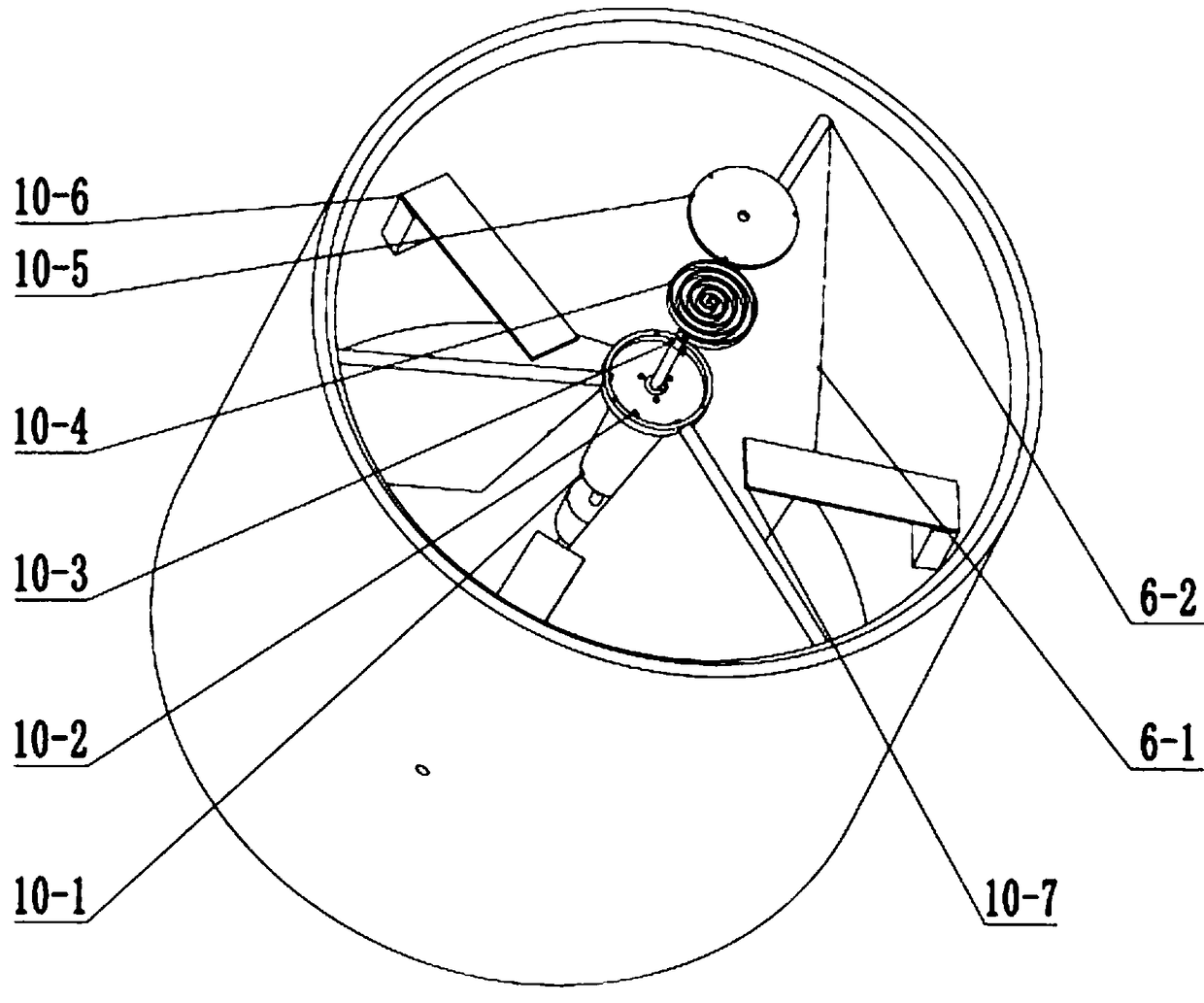

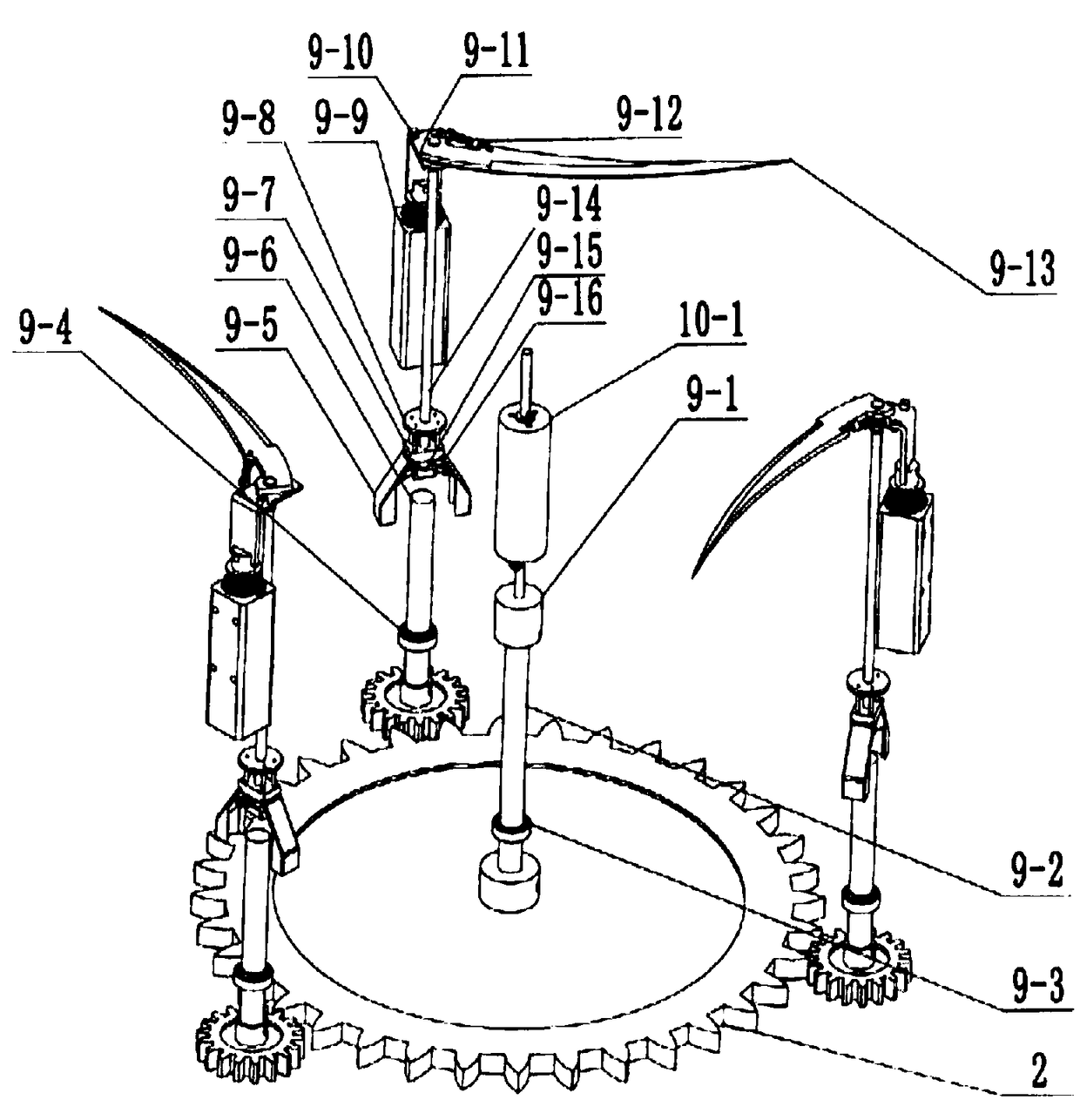

[0025] Such as figure 1 As shown, a robot end effector for cluster tomato picking mainly includes an outer cylinder 3, an inner cylinder 6, a cluster fruit collection mechanism 10, a fruit release mechanism 4 and three fruit stem rotary cutting mechanisms 9, wherein :

[0026] The inner cylinder 6 is fixed inside the outer cylinder 3 by screws, the two are coaxial, and the bottom of the outer cylinder 3 is fixed with a lower end cover 1 by screws, and the lower end cover 1 is used to protect the gear set 2 from external corrosion. There is a cylindrical shaft 6-2 in the center of the inner cylinder 6; the upper side of the inner wall of the outer cylinder 3 is fixed with an annular baffle 7 by screws, and the baffle 7 is used to prevent external debris from entering the outer cylinder 3 to protect the fruit stem Rotary cutting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com