Upflow continuous integral water purification equipment

A purification equipment and cylinder technology, applied in chemical instruments and methods, filtration and separation, gravity filters, etc., can solve the problems of secondary pollution of clean water, too simple structural design of sand washing device, blockage of sand washing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

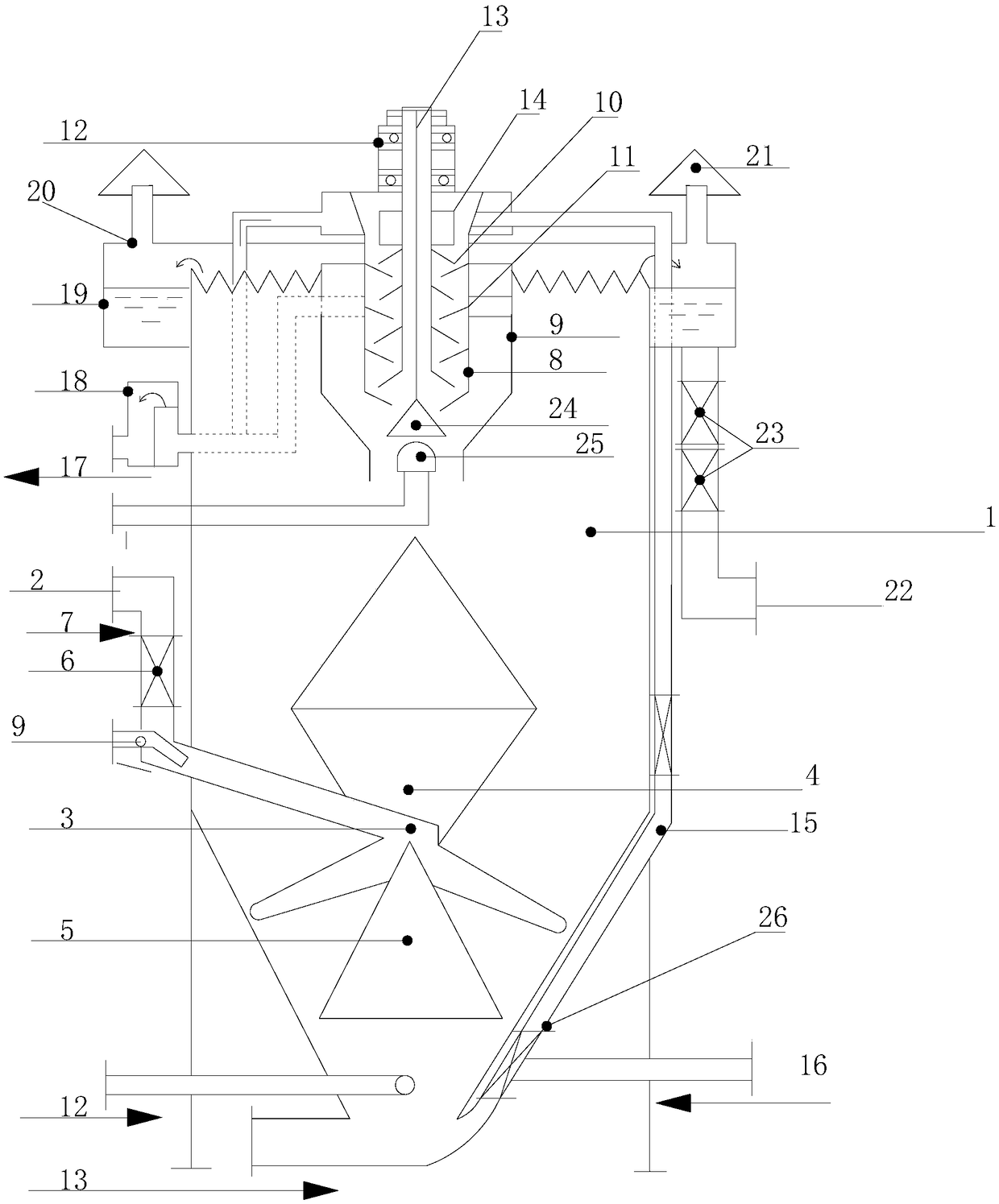

[0029] The present invention will be further explained below in conjunction with the accompanying drawings.

[0030] An upflow continuous integrated purification device disclosed by the present invention comprises a cylinder body 1, the bottom of the cylinder body 1 is conical, and the top is sealed. Sand washing and filtering system, with a compressed air sand lifting device on the outside;

[0031] The water inlet distribution system includes a water inlet pipe 2 and a water distributor 3 connected to the water inlet pipe 2. A conical distribution cover 4 is provided above the water distributor 3, and a triangular distribution cover 5 is provided below the water distributor 3; the water inlet pipe 2 extends Out of the cylinder body 1, the water inlet end of the water inlet pipe 2 is provided with a pipe mixer 6 and a compressed air inlet 7 in sequence from the outside to the inside;

[0032] The sand washing and filtering system includes a sand washing device 8, the sand wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com