Uranium-removing aluminum powder and method for removing uranium based on aluminum cans as raw material

The technology of cans and aluminum powder is applied in the field of uranium ore metallurgy, which can solve the problems of reducing the grade of secondary aluminum, wasting resources, destroying alloy components, etc., and achieves the effects of simple operation, easy availability of raw materials and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. The aluminum powder for removing uranium based on aluminum pop cans as raw material, its main components are Al-Mg-Mn alloy and a small amount of metal impurities, the mass fraction of each element is: Al 95.7%~96.7%, Mg 0.8%~1.3%, Mn 1.0%~1.5%, Fe 0.70%, Zn 0.25%, Si 0.30%, Cu0.25%.

[0021] Its concrete preparation steps are as follows:

[0022] Collect the discarded aluminum pop cans, wash them with water, dry them, break open the body of the aluminum pop cans, remove the lid and the bottom of the cans, then use sandpaper to remove the paint on the cans, clean them repeatedly with distilled water, and put them in the oven The drying temperature is 105°C, the drying time is 0.5h, and then the dried can body is cut into pieces, and then crushed and ground into a powder with a mesh size of 80 or less by a ball mill to obtain aluminum powder for removing uranium.

Embodiment 2

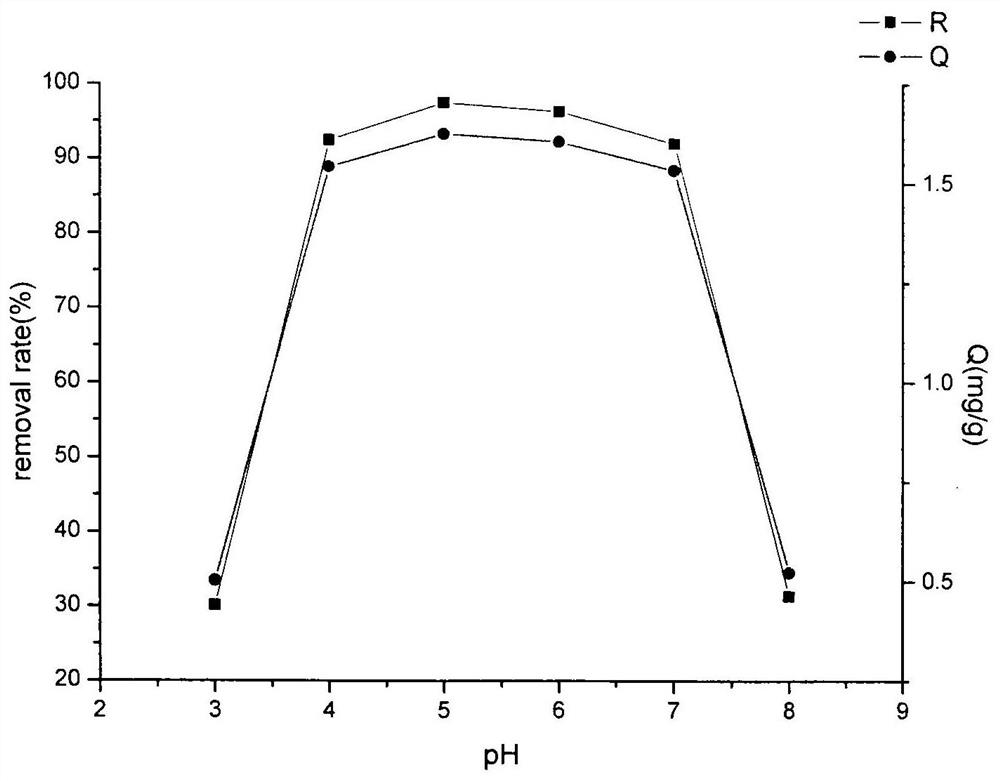

[0023] Embodiment 2. A method for removing uranium in uranium-containing wastewater based on aluminum pop cans as raw material for removing uranium from uranium-containing aluminum powder. The initial concentration of uranium in uranium-containing wastewater is 10 mg / L, and the pH value is 3 to 8. The specific operation steps are as follows:

[0024] The pH value of the uranium-containing wastewater was adjusted to 3, 4, 5, 6, 7, and 8 respectively, and the uranium-containing wastewater with different pH values was treated by adding aluminum powder for removing uranium. The dosage of aluminum powder for removing uranium was 6g / L. The reaction was oscillated by a constant temperature shaker, the rotation speed of the constant temperature shaker was 160r / min, the reaction temperature was 30°C, the reaction oscillation time was 120min, and solid-liquid separation was carried out after the reaction was completed.

[0025] After solid-liquid separation, filter, take the supernatan...

Embodiment 3

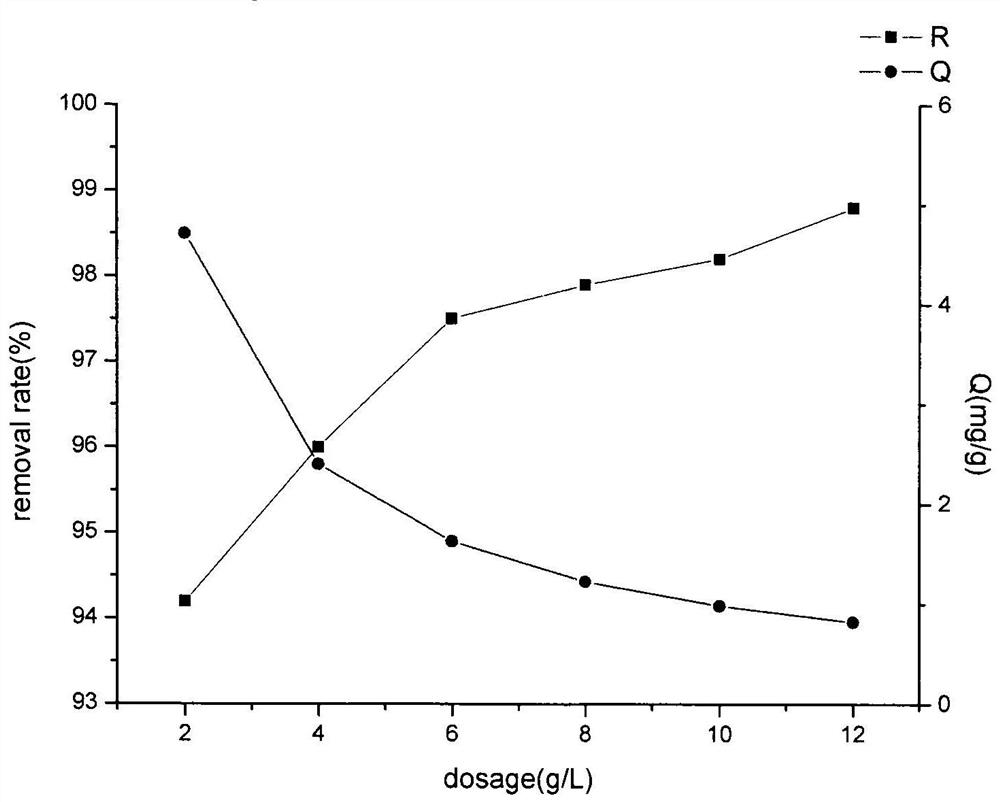

[0027] Embodiment 3. A method for removing uranium in uranium-containing wastewater by using aluminum pop cans as raw material for removing uranium in uranium-containing wastewater. The initial concentration of uranium in uranium-containing wastewater is 10 mg / L, and the pH value is 3 to 8. The specific operation steps are as follows:

[0028] The pH value of uranium-containing wastewater was adjusted to 5, and the dosage of aluminum powder for removing uranium was 2g / L, 4g / L, 6g / L, 8g / L, 10g / L, and 12g / L. The uranium-containing wastewater is treated, and the reaction is oscillated by a constant temperature shaker. The rotation speed of the constant temperature shaker is 160r / min, the reaction temperature is 30°C, and the reaction oscillation time is 120min. After the reaction, the solid-liquid separation is carried out.

[0029] After solid-liquid separation, filter, take the supernatant, and use a spectrophotometer to measure the residual uranium concentration in the uranium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com