Online detection device and detection method for rolling reduction of stirring head

A detection device and reduction technology, used in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of less research on welding thermal performance on-line detection, to ensure stability and accuracy, and ensure welding quality. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

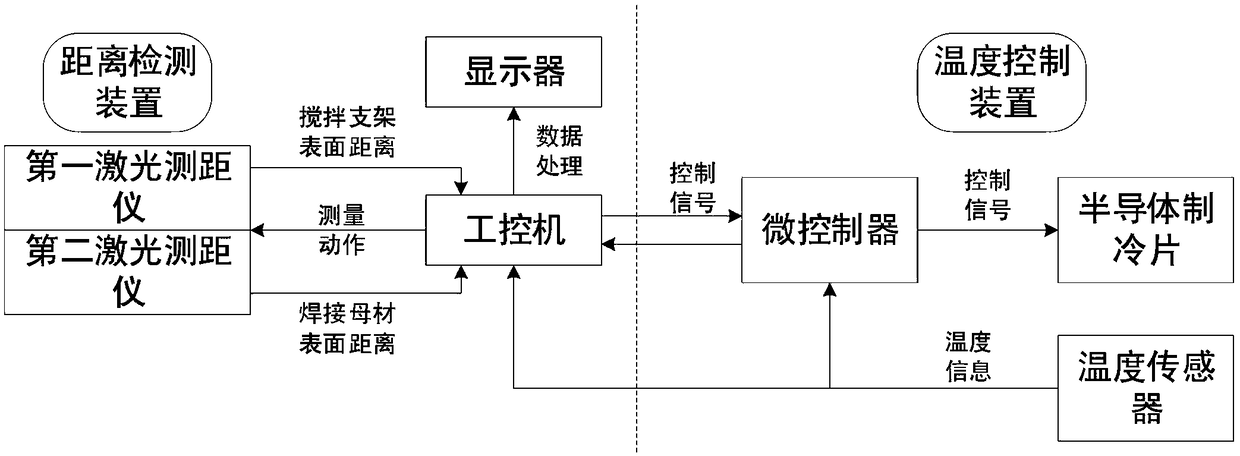

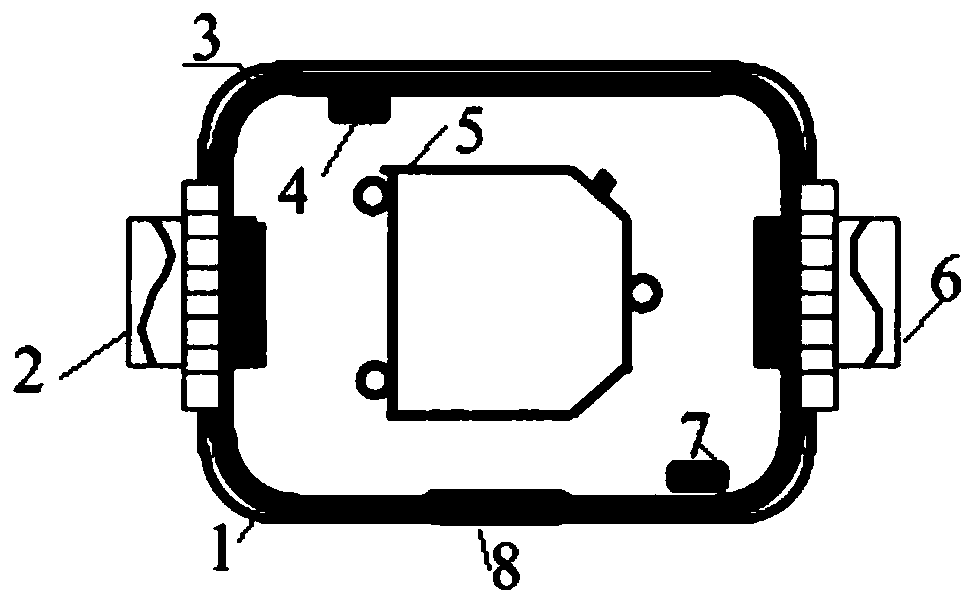

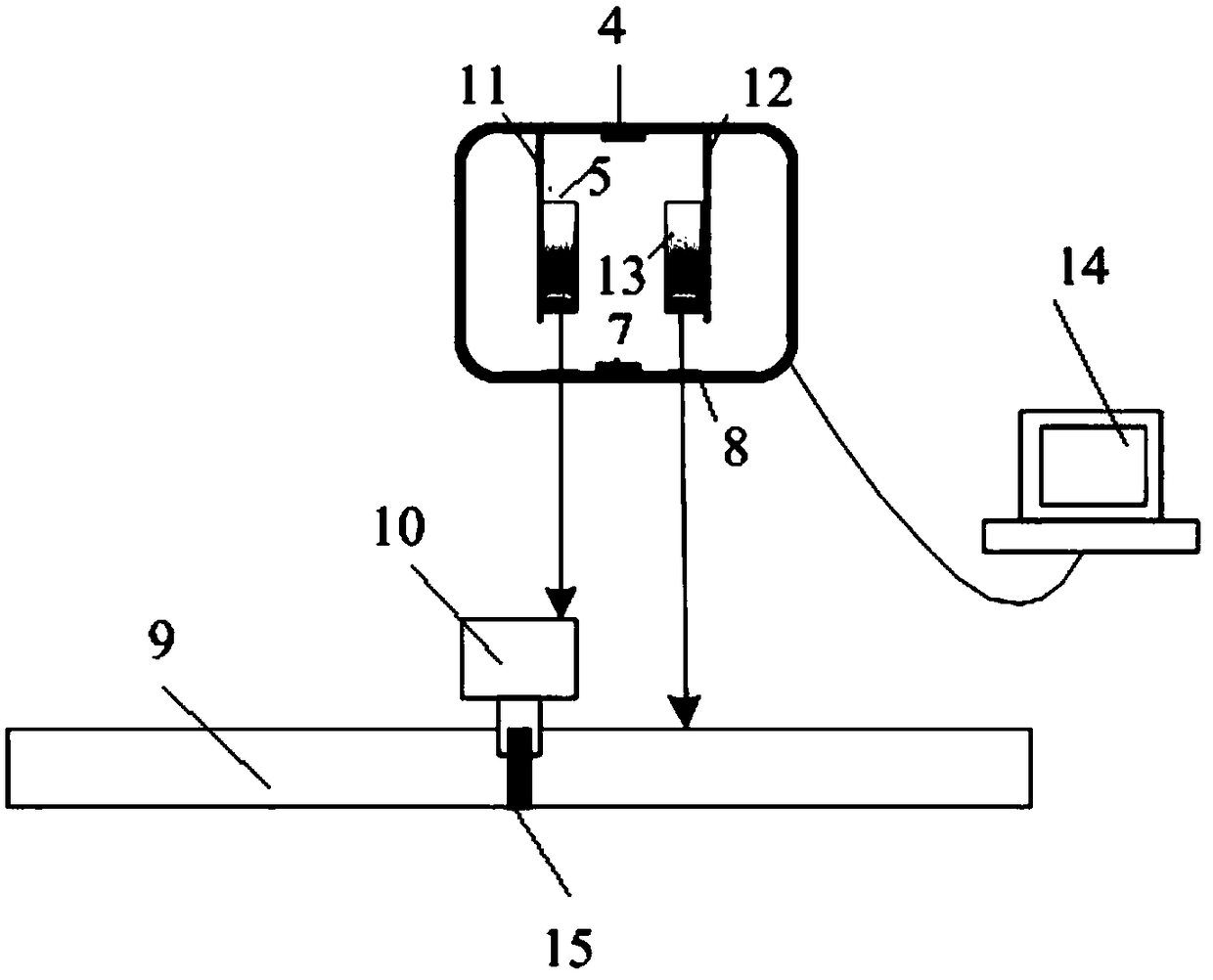

[0051] The detection system of stirring head depression of the present invention is as figure 1 As shown, it includes a distance measuring device and a temperature control device. The distance detecting device is mainly composed of a first laser range finder 5, a second laser range finder 13 and an industrial computer 1. Between the two laser range finders and the industrial computer For two-way communication, the temperature control device is mainly composed of the first group of temperature regulation modules 2, the second group of temperature regulation modules 6, the first temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com