System and method for laser processing transparent material through passive zoom

A transparent material, laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high probability of device damage, limited processing thickness, and many optical devices, and achieve low device cost and large thickness range. , the effect of less optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

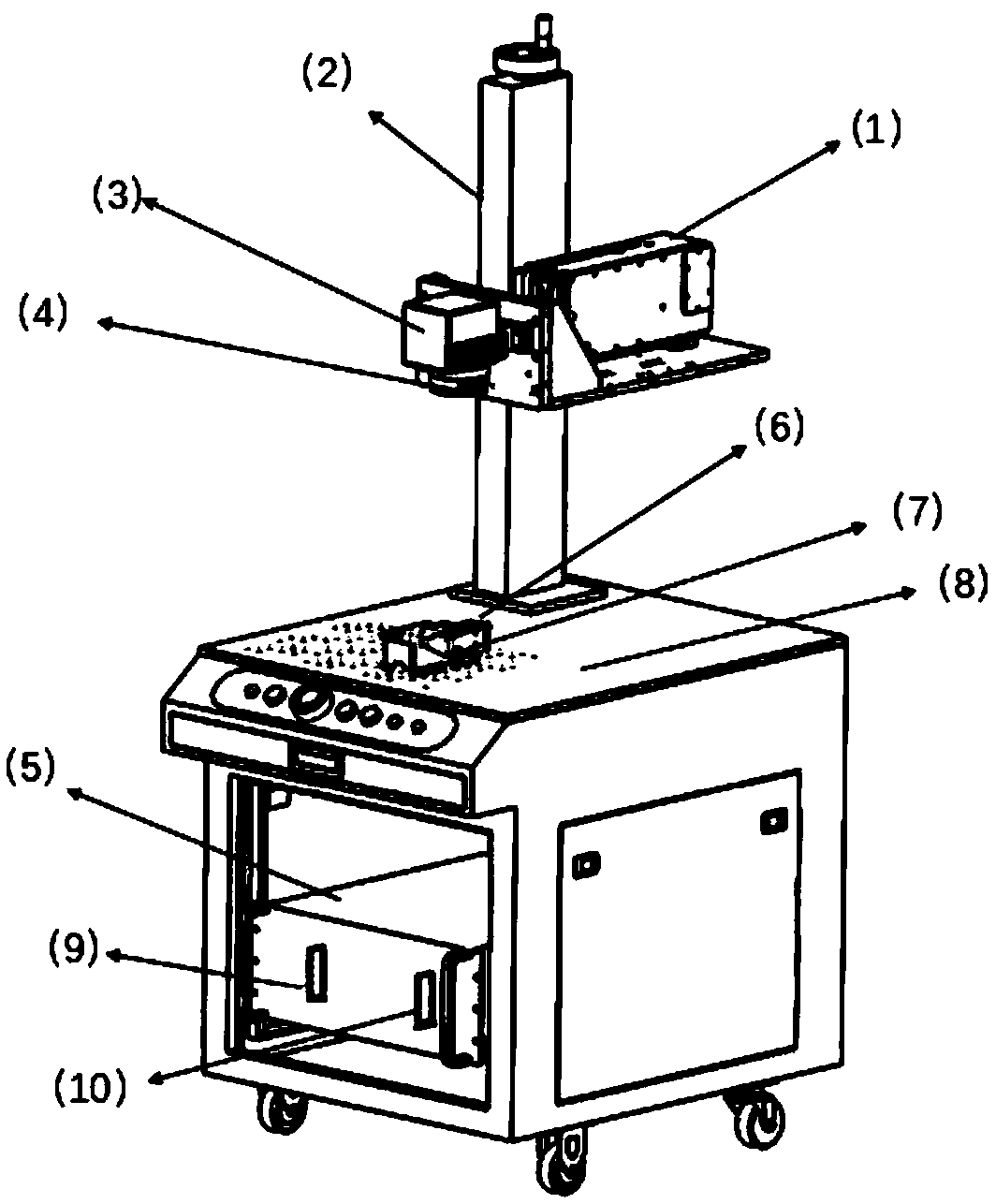

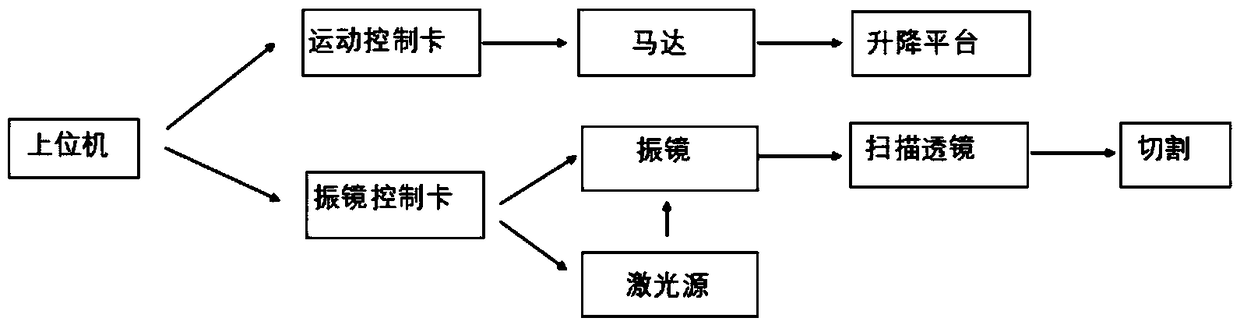

[0025] Such as figure 1 As shown, the passive zoom laser processing transparent material system of the present invention includes a laser source 1, a laser source support column 2, a galvanometer scanning head 3, a scanning lens 4, a host computer 5, a motor 6, an electronically controlled lifting platform 7, Platform bottom plate 8, motion control card 9 and vibrating mirror control card 10.

[0026] The platform bottom plate 8 is elastically connected to the electric control lifting platform 7; the laser source support column 2 is located on the upper side of the electric control lifting platform 7, and is fixedly connected to the platform bottom plate 8; the laser source 1 is fixedly connected to the laser source support column 2, and the platform bottom plate 8 The flatness and parallelism of the upper and lower sides are guaranteed by pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com