A fuel cell vehicle energy-saving air supply system

A gas supply system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, power system fuel cells, etc., can solve the problems of increasing system complexity, wasting hydrogen power, and low energy recovery efficiency, so as to improve energy utilization High efficiency, easy integration, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

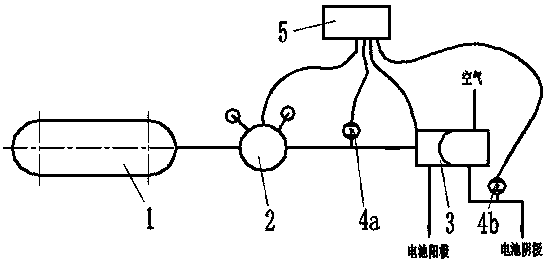

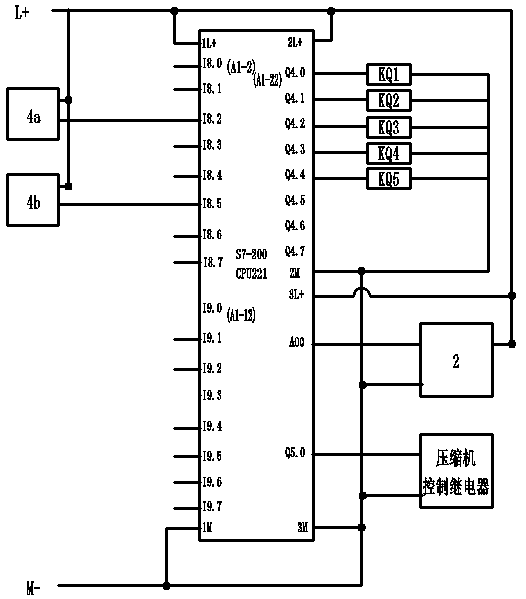

[0013] figure 1 A schematic diagram of an energy-saving gas supply system for a fuel cell vehicle is shown. This energy-saving gas supply system for fuel cell vehicles includes a high-pressure hydrogen cylinder 1 for vehicles, a decompression solenoid valve 2, a multi-purpose compressor 3, a pressure sensor and a control system 5, and the pressure sensor includes a pressure sensor 4a at the hydrogen inlet end, and a pressure sensor at the air outlet end. Sensor 4b. The high-pressure hydrogen cylinder 1 for vehicles is connected to the decompression solenoid valve 2 through a pipeline, and the outlet of the decompression solenoid valve 2 is connected to the hydrogen inlet of the multipurpose compressor 3, and the air inhaled by the other end of the multipurpose compressor 3 is compressed, and the compressed The air is directly used for the cathode of the battery stack; the air inlet port of the multipurpose compressor 3 is filtered air in the atmosphere, and the lower pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com