Glass-ceramic

A technology of glass-ceramics and grain size, which is applied in the field of glass-ceramics with high dielectric constant, can solve problems such as restricting development, and achieve the effects of high relative dielectric constant, efficient and stable production, and uniform internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

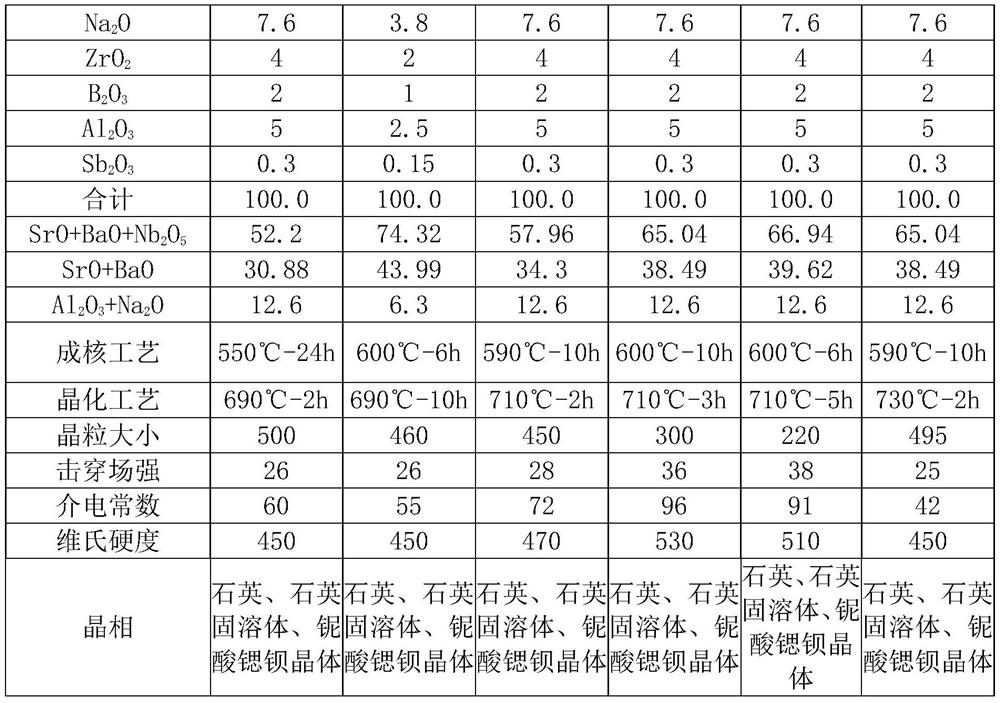

[0019] Glass-ceramics, also known as glass-ceramics, is a material that is crystallized inside the glass by heat-treating the glass. The glass-ceramic of the present invention is a material having a crystalline phase and a glass phase, as distinguished from amorphous and crystalline solids. Glass ceramics can have properties that cannot be obtained in glass, such as properties such as dielectric constant and hardness, due to crystals dispersed in the interior.

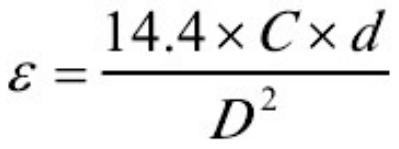

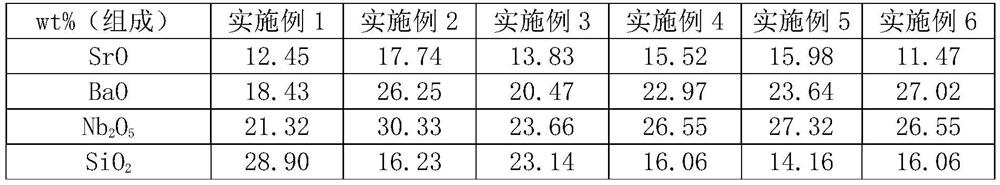

[0020] After repeated tests and researches, the inventor obtained the glass-ceramic of the present invention at a relatively low cost by specifying the content and content ratio of the specific components constituting the glass-ceramic to a specific value and making it precipitate a specific crystal phase. . Next, the composition range of each component of the glass ceramics of this invention is demonstrated. In this specification, unless otherwise specified, the content of each component is expressed in % by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com