Conductive coating for voice coil welding lead, and voice coil welding lead technology

A technology for welding wires and conductive coatings, applied in conductive coatings and other directions, can solve problems such as the influence of voice coil welding wire performance, influence on tin on copper foil, easy oxidation of copper foil, etc. Condition-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

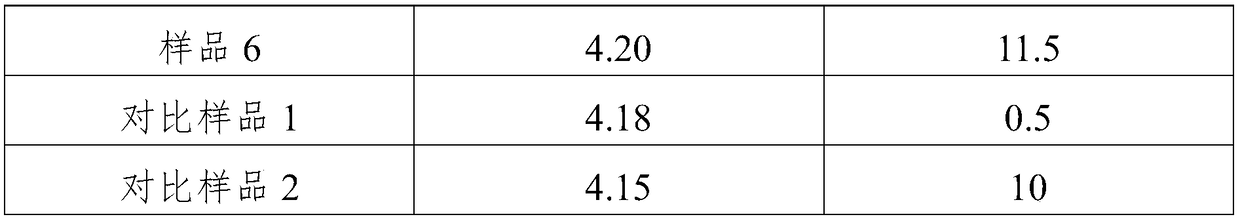

Examples

Embodiment 1

[0031] The conductive coating used for voice coil welding wire of the present embodiment, the preparation method of this conductive coating comprises the following steps:

[0032] 1) Weigh 500 grams of SV glue, 400 grams of conductive silver powder, 50 grams of stabilizer 201P, and 400 grams of methanol, and set aside;

[0033] 2) Under stirring conditions, slowly add SV glue, conductive silver powder, and 201P into methanol successively, and stir thoroughly until a uniform emulsion is formed.

Embodiment 2

[0035] The conductive coating used for voice coil welding wire of the present embodiment, the preparation method of this conductive coating comprises the following steps:

[0036] 1) Weigh 500 grams of epoxy adhesive, 400 grams of conductive copper powder, 40 grams of 201P, and 480 grams of ethanol for subsequent use;

[0037] 2) Under stirring conditions, slowly add epoxy adhesive, conductive copper powder, and 201P into ethanol successively, and stir well until a uniform emulsion is formed.

Embodiment 3

[0039] The conductive coating used for voice coil welding wire of the present embodiment, the preparation method of this conductive coating comprises the following steps:

[0040] 1) Weigh 600 grams of SV glue, 400 grams of conductive silver powder, 50 grams of 201P, and 500 grams of methanol, and set aside;

[0041] 2) Under stirring conditions, slowly add SV glue, conductive silver powder, and 201P into methanol successively, and stir thoroughly until a uniform emulsion is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com