A kind of stirring method of conductive adhesive

A stirring method and conductive adhesive technology, applied in the direction of conductive adhesives, etc., can solve the problems of weaker fixing support of conductive adhesives, poor density of conductive adhesives, and many internal bubbles, etc., to solve poor resistance consistency and reduce voids Quantity, effect of increasing shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

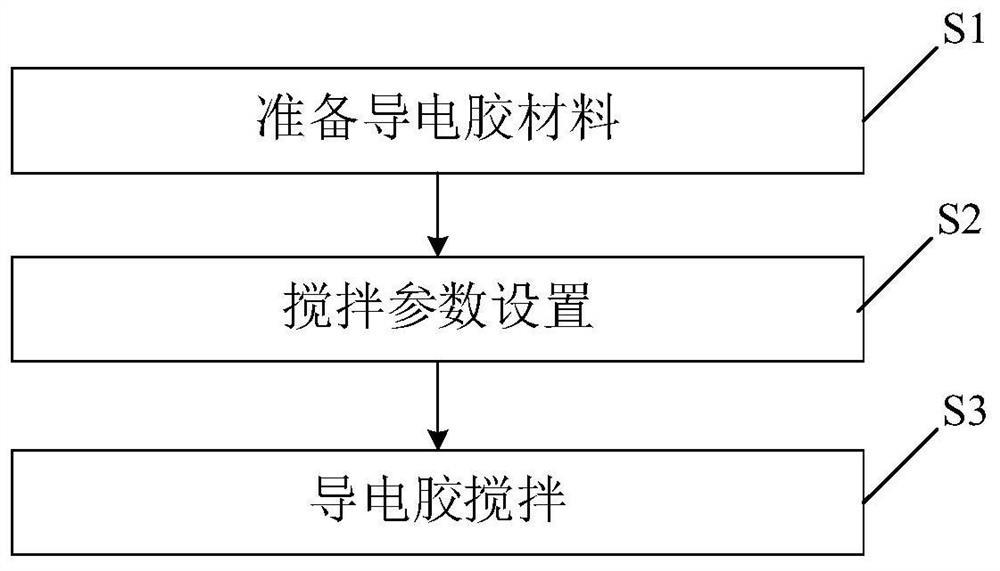

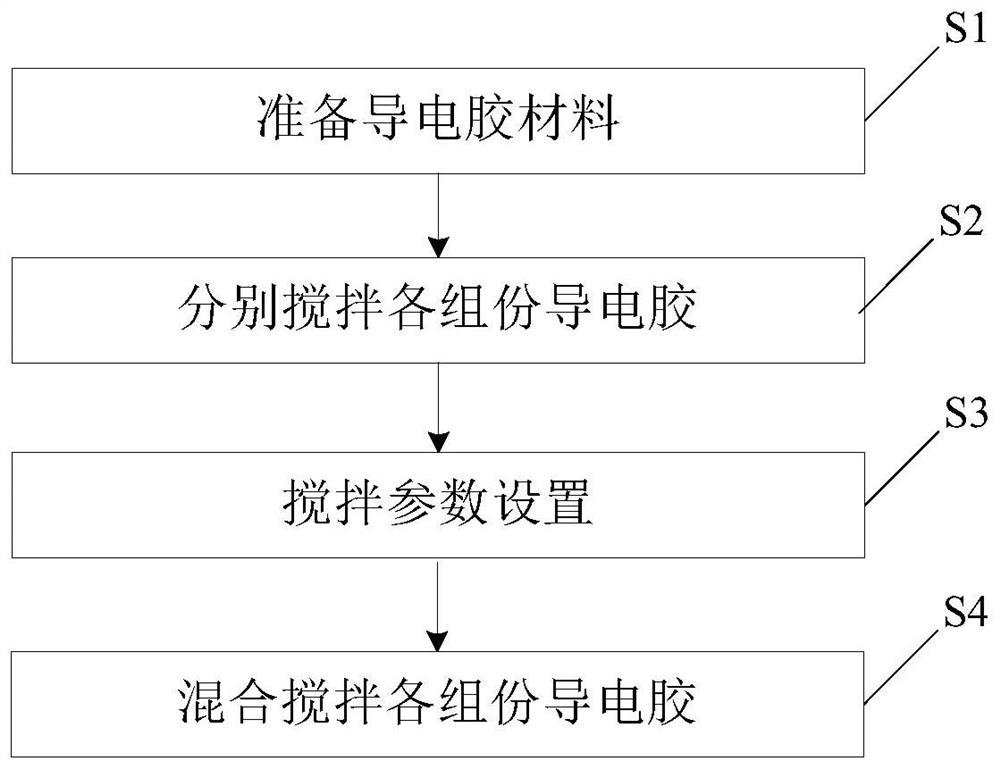

Method used

Image

Examples

Embodiment Construction

[0049] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0050] Conductive adhesive is an adhesive with certain conductive properties after curing or drying. It usually uses matrix resin and conductive fillers, namely conductive particles, as the main components. The conductive particles are combined through the bonding effect of the matrix resin to form a conductive adhesive. Pathway to realize the conductive connection of the adhered material. Since the matrix resin of the conductive adhesive is an adhesive, an appropriate curing temperature can be selected for bonding. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com