Preparation method of hot-dipping sweet strawberry wine

A strawberry wine, hot dipping technology, applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of insufficient aftertaste, weak taste, prominent sour taste, etc., to reduce costs and reduce the use of sulfur dioxide Links, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

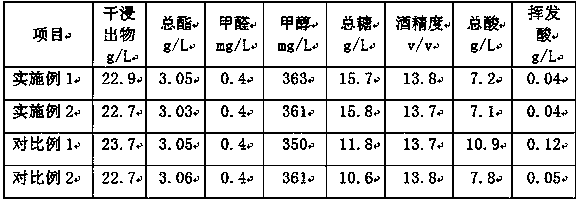

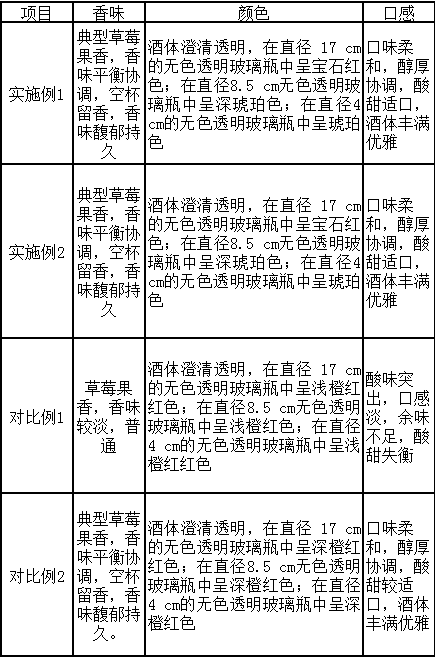

Examples

Embodiment 1

[0021] (1) Cleaning and disinfection: cleaning and disinfection of fermentation vessels and equipment;

[0022] (2) Raw material beating: Strawberries are manually sorted after harvesting to remove moldy and rotten strawberry fruits. After crushing, the juice residue is separated to obtain strawberry pulp, and 0.25‰ of pectinase is added to treat the strawberry pulp;

[0023] (3) Hot dipping: Based on the weight of fresh strawberry raw materials, add 1.5 times of boiling water to make the temperature reach 60°C, soak for 10 minutes, and separate the juice residue to obtain strawberry pulp. According to the weight of strawberry pulp, add 20% white granulated sugar (sucrose), stir to fully dissolve the sugar;

[0024] (4) Ingredients blending: After the strawberry pulp is cooled to room temperature, add 1‰ citric acid (food grade), 1.5‰ lactic acid (food grade), 0.2‰ malic acid (food grade) and 0.3‰ single Nitric acid (food grade), fermented nutritional aid, fully stirred. Acc...

Embodiment 2

[0031] (1) Cleaning and disinfection: cleaning and disinfection of fermentation vessels and equipment;

[0032] (2) Raw material beating: Strawberries are manually sorted after harvesting to remove moldy and rotten strawberry fruits. After crushing, the juice residue is separated to obtain strawberry pulp, and 0.25‰ of pectinase is added to treat the strawberry pulp;

[0033] (3) Hot dipping: Based on the weight of fresh strawberry raw materials, add 1.5 times of boiling water to make the temperature reach 70°C, soak for 10 minutes, and separate the juice residue to obtain strawberry pulp. According to the weight of strawberry pulp, add 20% white granulated sugar (sucrose), stir to fully dissolve the sugar;

[0034] (4) Ingredients blending: After the strawberry pulp is cooled to room temperature, add 1‰ citric acid (food grade), 1.5‰ lactic acid (food grade), 0.2‰ malic acid (food grade) and 0.3‰ single Nitric acid (food grade), fermented nutritional aid, fully stirred. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com