Microfluidic chip, chip manipulation system and microfluidic apparatus for nucleic acid extraction, and nucleic acid extraction method

A microfluidic chip and manipulation system technology, applied in the fields of diagnosis and detection, and biomedicine, can solve the problems of increasing the error probability of nucleic acid extraction operations and reducing the efficiency of nucleic acid extraction, so as to reduce the probability of operation errors, save operation time, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

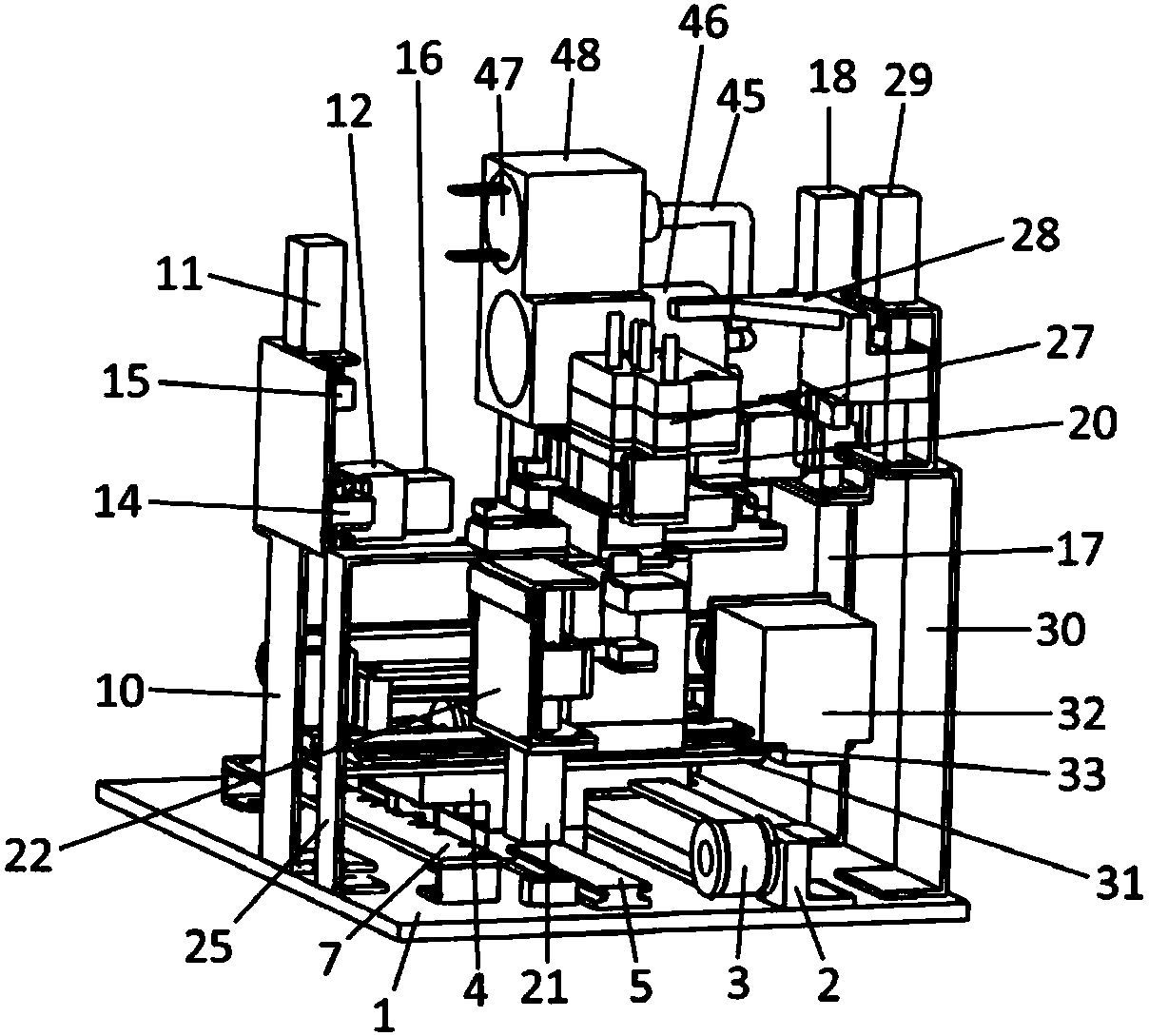

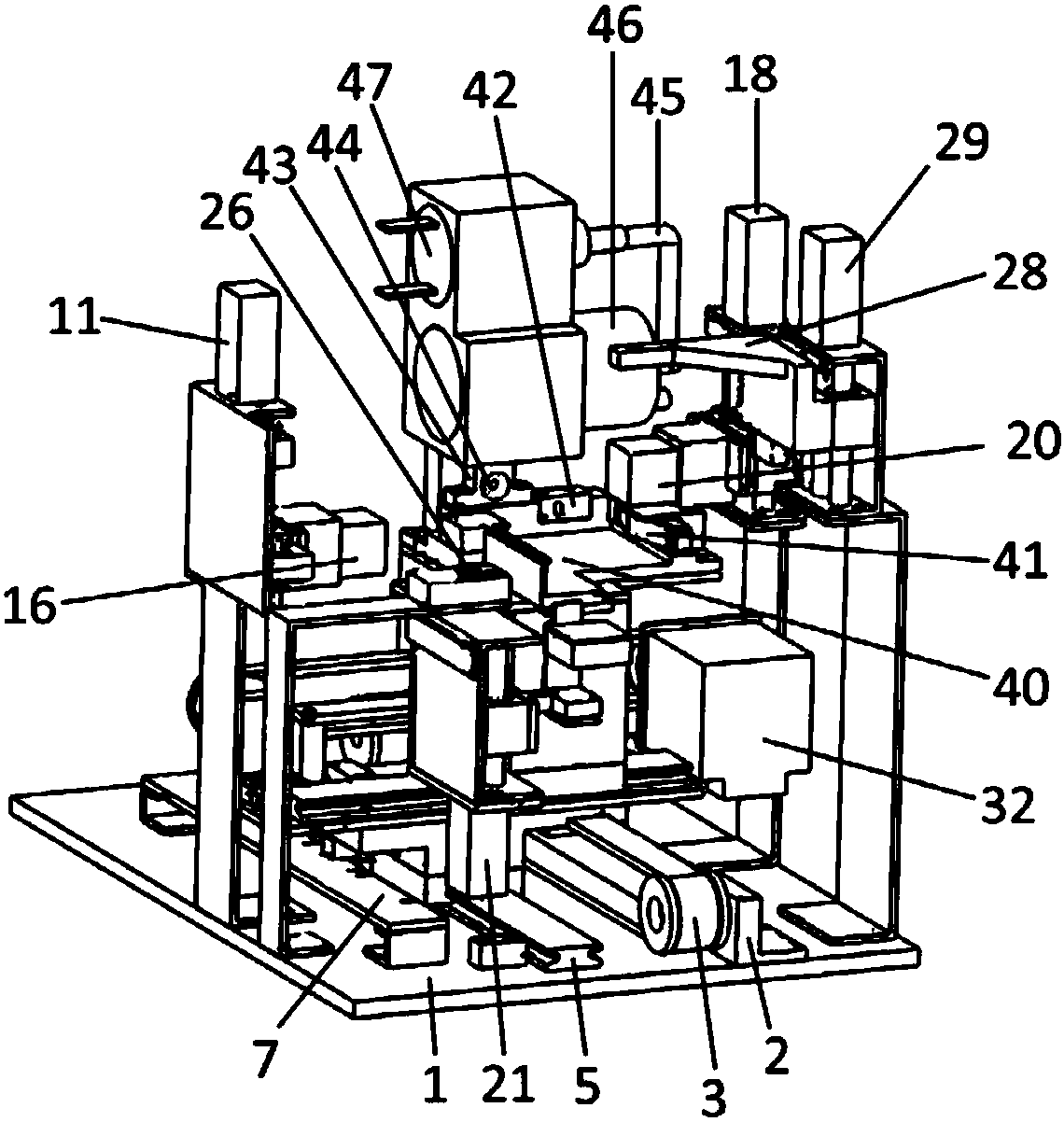

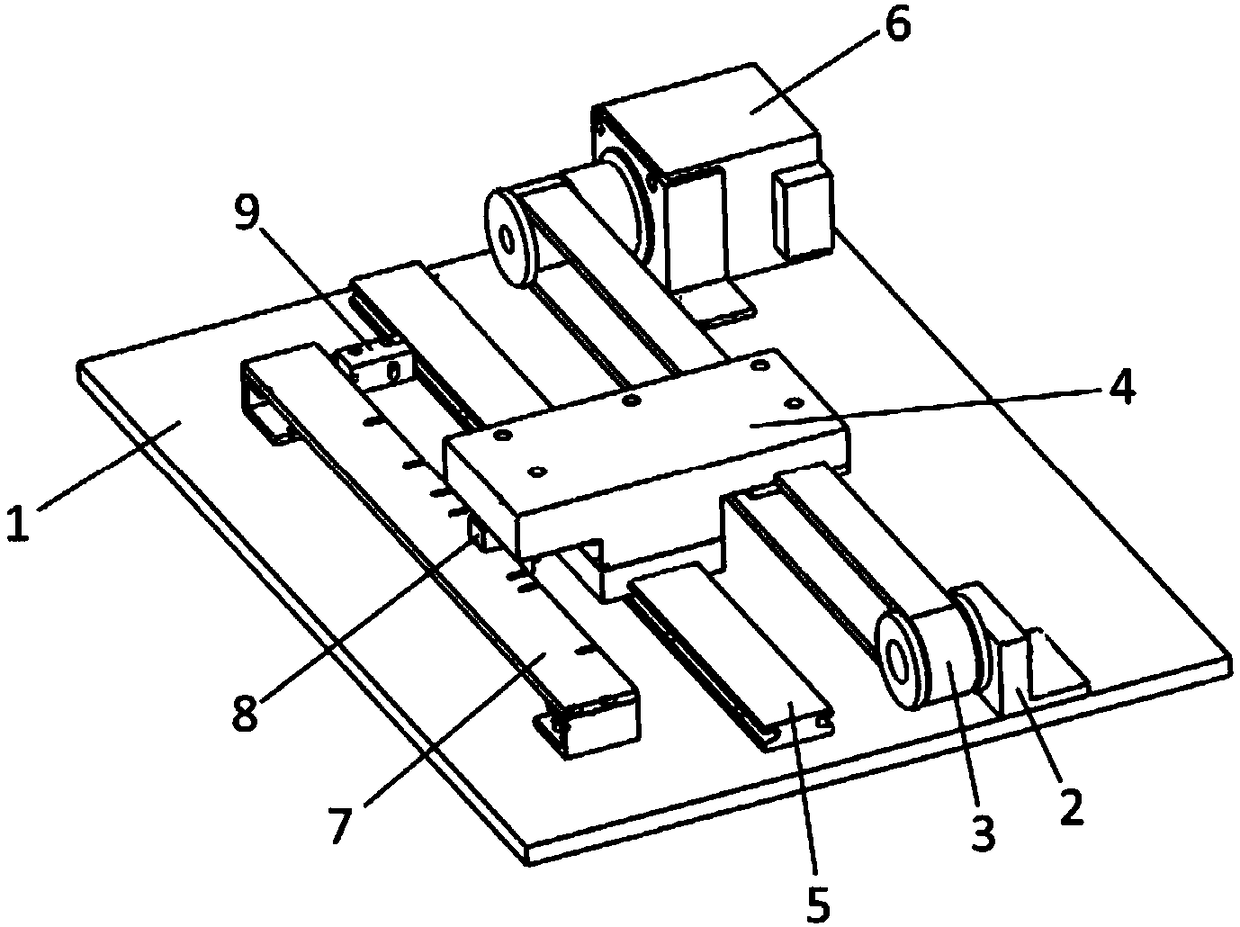

[0104] Figure 1 to Figure 1 2 shows the structure of the microfluidic device for nucleic acid extraction and its microfluidic chip according to the first embodiment of the present invention. The microfluidic device includes a microfluidic chip 27 for nucleic acid extraction and a chip manipulation system for nucleic acid extraction. The chip manipulation system is coupled with the microfluidic chip 27 and controls the microfluidic chip 27 to perform nucleic acid extraction.

[0105] see figure 1 , Figure 7 and Figure 8 . In the first embodiment, the microfluidic chip 27 includes a storage cavity cover 50, a reagent storage structure 54, a puncture structure 55, a communication structure 56, a reaction structure 60, and a waste liquid storage structure arranged in sequence from top to bottom. Sheet 66 and bottom sheet 69 of the waste chamber. In addition, the elution chamber cover sheet 65 is also included.

[0106] The storage chamber cover sheet 50 is located above ...

no. 2 example

[0178]As shown in Figure 13, the difference between the second embodiment and the first embodiment is: in the microfluidic chip 27, the mixing chamber 61 and the elution chamber 63 are vertical structures, and the hose 62 is vertically placed and connected to the mixing chamber 61 Between the elution chamber 63 , the waste liquid removal channel 70 is located at the bottom of the elution chamber 63 , and the waste liquid chamber air hole 68 is located at the top of the waste liquid chamber 67 . Correspondingly, the closing slider 23 of the chip manipulation system is located on the side of the microfluidic chip 27, and driven by the hose closing motor 21, the closing slider 23 moves horizontally to squeeze the hose 62 to achieve the closing effect. At the same time, the heating film 24 fixed on the closing slider 23 is attached to the side wall of the elution chamber 63 .

[0179] When the waste liquid in the mixing chamber 61 needs to be discharged to the waste liquid chamber...

no. 3 example

[0182] Such as Figure 14 As shown, the difference between the third embodiment and the first embodiment is that the pressure control component of the chip handling system is not a vacuum suction component, but a solenoid valve 73 and a rubber plug 72 connected to the end of the solenoid valve 73 . Wherein, the gas hole 68 of the waste liquid chamber is arranged above the waste liquid chamber 67 , and the solenoid valve 73 is used to control the opening and closing of the gas hole 68 of the waste liquid chamber.

[0183] The electromagnetic valve 73 drives the rubber plug 72 to close the waste liquid chamber pore 68 downwards when it is in the open state, so that the inside of the waste liquid chamber 67 forms a closed space. During the reaction process, the liquid reagent in the mixing chamber 61 stays at The mixing chamber 61 does not flow downward. The solenoid valve 73 drives the rubber stopper 72 to move upwards in the closed state, the waste liquid chamber air hole 68 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com