Electrospinning device for preparing short fiber felt and preparation method thereof

A short fiber and electrospinning technology, which is applied in fiber processing, textiles, papermaking, non-woven fabrics, etc., can solve the problems of cumbersome preparation steps, unsuitable for mass production, and restrictions on the application of nano-short fibers, and achieve the effect of simplifying the preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

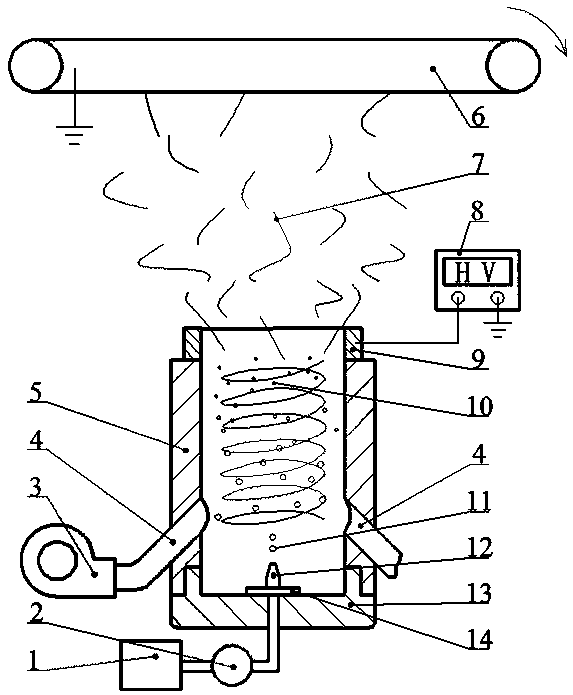

Embodiment 1

[0038] In this embodiment, the air inlet pipe 4 and the swirl chamber 5 have an axial angle of 45° (upward is positive), a tangential angle of 30°, and a radial angle of 30° (inward is positive); the solution used is PEO solution, and the solute It is PEO, the solvent is alcohol and distilled water, the volume ratio is 1:1, the solution concentration is 16%; the inner diameter of the nozzle 12 is 210 μm.

[0039] Based on above-mentioned device, embodiment 1 is as follows about the preparation method of nano-short fiber mat:

[0040] 1) Put the PEO solution into the liquid storage tank 1, set the flow rate of the droplet generator 2 to 700 μl / hr, and the frequency of the droplet 11 to be 3 Hz.

[0041] 2) Turn on the two fans 3 and set the flow rate of the pumped gas to 3.6m / s to generate a swirl in the swirl chamber 5, at which time the swirl chamber 5 produces a large number of fragmented droplets 10.

[0042] 3) Turn on the high-voltage electrostatic generator 8, set the v...

Embodiment 2

[0045] In this embodiment, the air inlet pipe 4 and the swirl chamber 5 form an axial angle of 45° (upward is positive), a tangential angle of 45°, and a radial angle of 50° (inward is positive); the solution used is PVDF solution, and the solute It is PVDF, the solvent is acetone and DMF, the volume ratio is 1:1, the solution concentration is 15%; the inner diameter of the nozzle 12 is 210 μm.

[0046] Based on above-mentioned device, embodiment 2 is as follows about the preparation method of nano-short fiber:

[0047] 1) Put the PVDF solution into the liquid storage tank 1, set the flow rate of the droplet generator 2 to 500 μl / hr, and the frequency of the droplet 11 to be 3 Hz.

[0048] 2) Turn on the two fans 3 and set the flow rate of the pumped gas to 2.7m / s to generate a swirl in the swirl chamber 5, at which time the swirl chamber 5 produces a large number of fragmented droplets 10.

[0049] 3) Turn on the high-voltage electrostatic generator 8, set the voltage output v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Average fiber length | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com