An expanded-diameter extrusion friction anchor rod and anchor cable structure

An anchor rod and anchor cable technology, which is used in the installation of anchor rods, infrastructure engineering, construction, etc., can solve the problems of damaged anchor rod work performance, constant resistance instability, poor impact resistance, etc., and achieves easy design, processing and production. On-site installation, stable structure with constant resistance and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

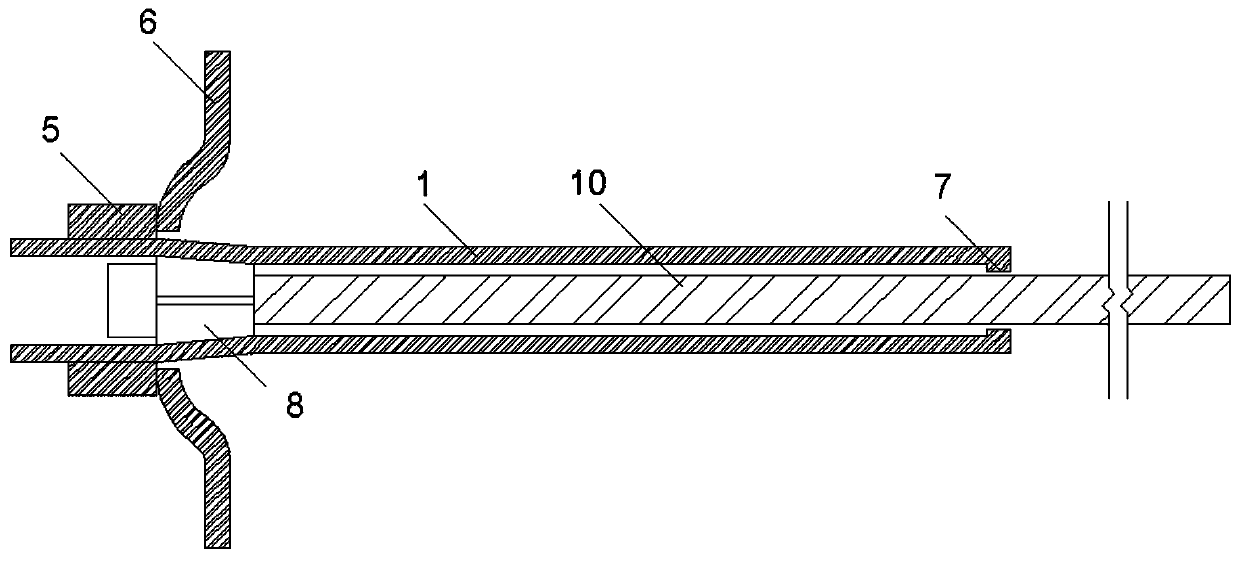

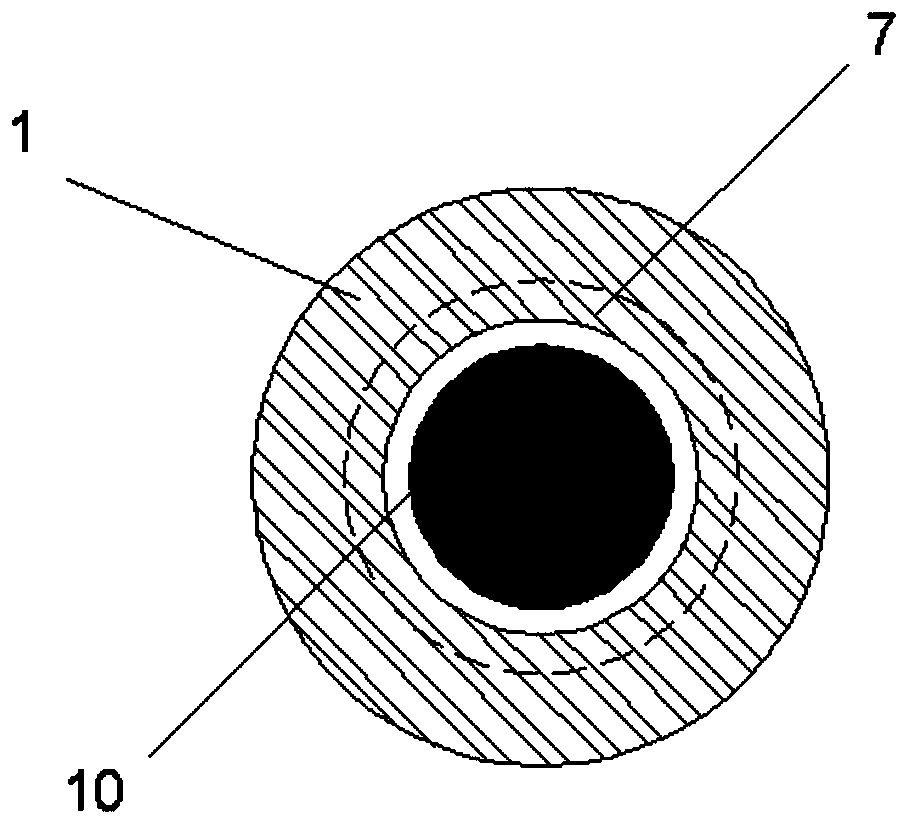

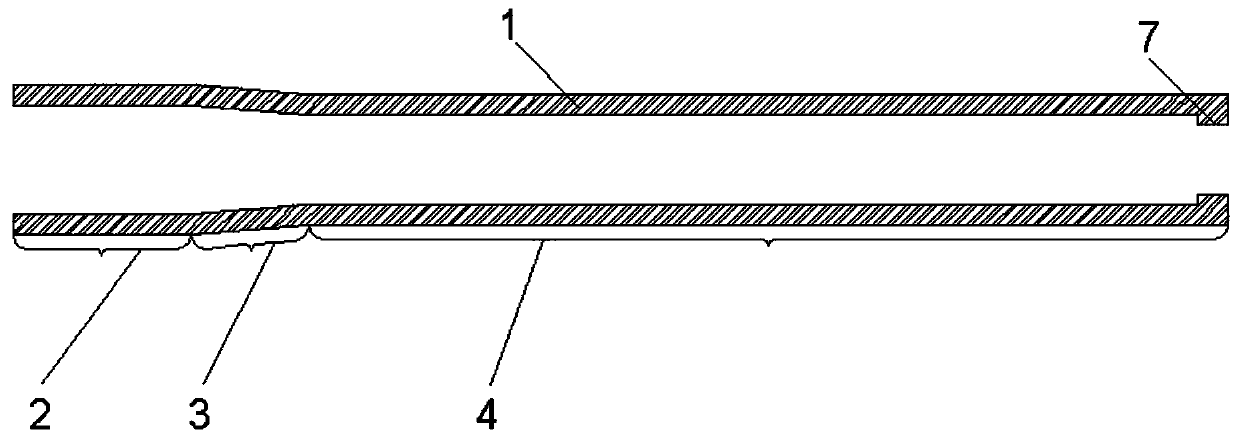

[0034] Such as Figure 1 ~ Figure 3 and Figure 4-1 to Figure 4-3 As shown, a diameter-expanding extruded friction anchor structure is an external type, including a casing 1, and the casing 1 includes a large-diameter area 2, an enlarged-diameter area 3, and a small-diameter area 4 , the outer wall of the large diameter area 2 of the casing 1 is screwed with a nut 5, the nut 5 is set as a high-strength nut, and the end of the nut 5 close to the expansion area 3 of the casing 1 is provided with a tray 6, and the tray 6 is set as a metal butterfly As for the tray, a stopper 7 is provided at the end of the small diameter area 4 of the casing 1 away from the expansion area 3, and the stopper 7 and the small diameter area 4 are integrally formed or the stopper 7 is screwed to the small diameter area 4, and the stopper The installation method of 7 and small diameter area 4 can be selected according to the specific construction requirements, and the inner diameter of the through hol...

Embodiment 2

[0036] Such as Figure 5 and Figure 6-1 to Figure 6-3 As shown, a diameter-expanding extruded friction anchor cable structure is external, including a casing 1, and the casing 1 includes a large-diameter area 2, an enlarged-diameter area 3, and a small-diameter area 4 , the outer wall of the large diameter area 2 of the casing 1 is screwed with a nut 5, the nut 5 is set as a high-strength nut, and the end of the nut 5 close to the expansion area 3 of the casing 1 is provided with a tray 6, and the tray 6 is set as a metal butterfly As for the tray, a stopper 7 is provided at the end of the small diameter area 4 of the casing 1 away from the expansion area 3, and the stopper 7 and the small diameter area 4 are integrally formed or the stopper 7 is screwed to the small diameter area 4, and the stopper The installation method of 7 and small diameter area 4 can be selected according to specific construction requirements, and the inner diameter of the through hole of the stopper 7 ...

Embodiment 3

[0038] Such as Figure 7 and Figure 8 As shown, a diameter-expanding extruded friction anchor structure is built-in, and includes a sleeve 1, and the sleeve 1 includes a large-diameter area 2, an enlarged-diameter area 3, and a small-diameter area 4, The small diameter area 4 of the casing 1 is provided with a limiter 7 in the inner hole at one end away from the enlarged diameter area 3, and the limiter 7 and the small diameter area 4 are integrally formed or the limiter 7 is screwed with the small diameter area 4, and the limiter The installation method of 7 and small diameter area 4 can be selected according to the specific construction requirements, and the inner diameter of the through hole of the stopper 7 is larger than the outer diameter of the rod body 10, and the stopper 7 can be limited after the bolt expander 8 reaches the maximum slippage. Its displacement continues to exert the mechanical properties of the rod body 10 and the casing 1 itself. The large diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com