A superjunction IGBT with a shielded gate and a manufacturing method thereof

A shielding gate and gate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasingly higher and higher requirements for the reduction range, and achieve higher turn-on and turn-off speeds , Improve the extraction speed and reduce the effect of switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

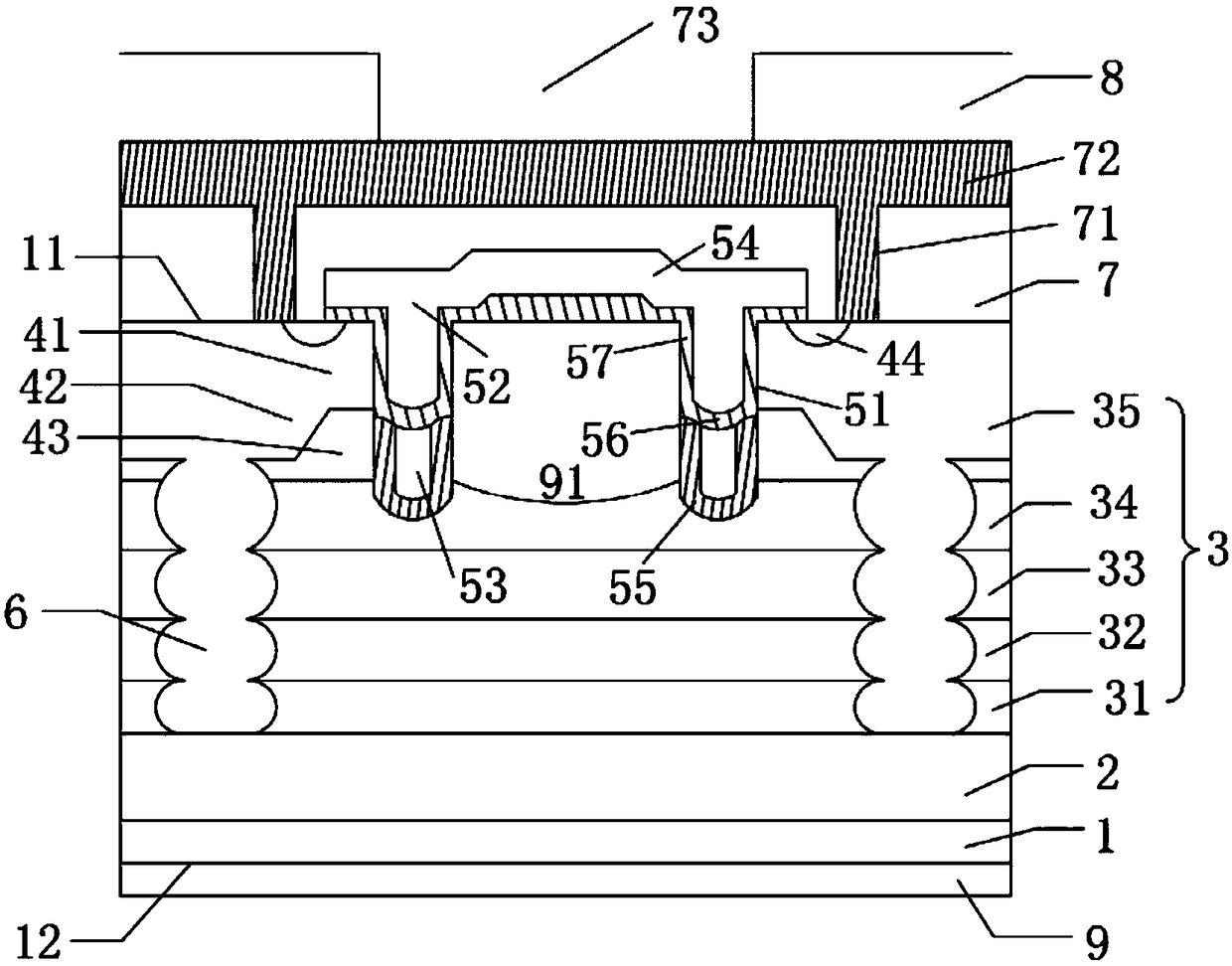

[0066] combine Figure 1 to Figure 12 As shown, this implementation provides a method for manufacturing a super-junction IGBT with a shielded gate, which is used to manufacture the super-junction IGBT described in Embodiment 1, including the following process steps:

[0067] S1. Provide a semiconductor substrate having a first main surface 11 and a second main surface 12, wherein P columns 6 are formed in the semiconductor substrate;

[0068] Wherein, step S1 specifically includes:

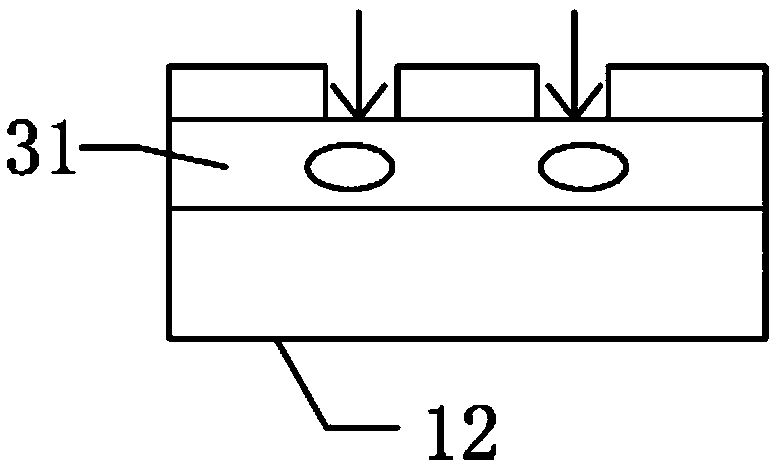

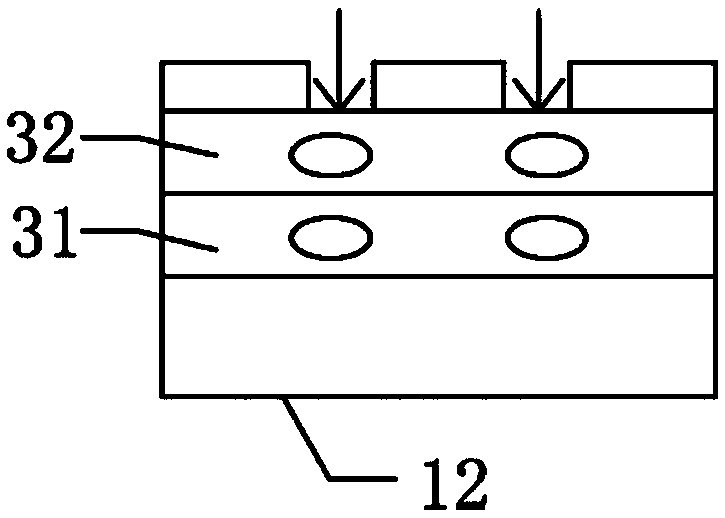

[0069] S111. Combine figure 1 with figure 2 As shown, a semiconductor substrate having a first epitaxial layer 31 of a first conductivity type and a second main surface 12 is provided, and the first epitaxial layer 31 of a first conductivity type and the second main surface 12 are arranged opposite to each other;

[0070] S112. Form a photoresist on the first epitaxial layer 31 of the first conductivity type, define the implantation region of the P column 6 by photolithography, inject impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com