Thin film transistor and preparation method thereof, and array substrate

A technology of thin-film transistors and metal layers, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as TFT electrical instability, passivation film faults, and lower product yields, and achieve improved contact Performance, avoid chamfering, improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of a thin film transistor, the preparation method comprising the following steps:

[0045] providing a substrate;

[0046] forming a gate and a gate insulating layer on the substrate, and the gate insulating layer covers the gate;

[0047] forming a first metal layer on the gate insulating layer, the first metal layer including a first electrode and a second electrode disposed on the gate insulating layer at intervals;

[0048] An active layer and a second metal layer are formed on the first metal layer, the second metal layer includes a source electrode and a drain electrode arranged at intervals, one end of the active layer is sandwiched between the first electrode and the source electrode, and the active layer The other end of is sandwiched between the second electrode and the drain;

[0049] A passivation layer is deposited, and the passivation layer covers the exposed surfaces of the source electrode, the d...

Embodiment 1

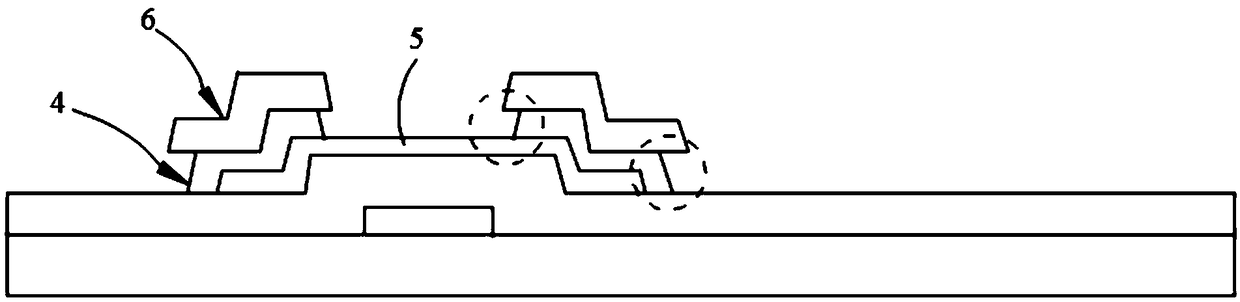

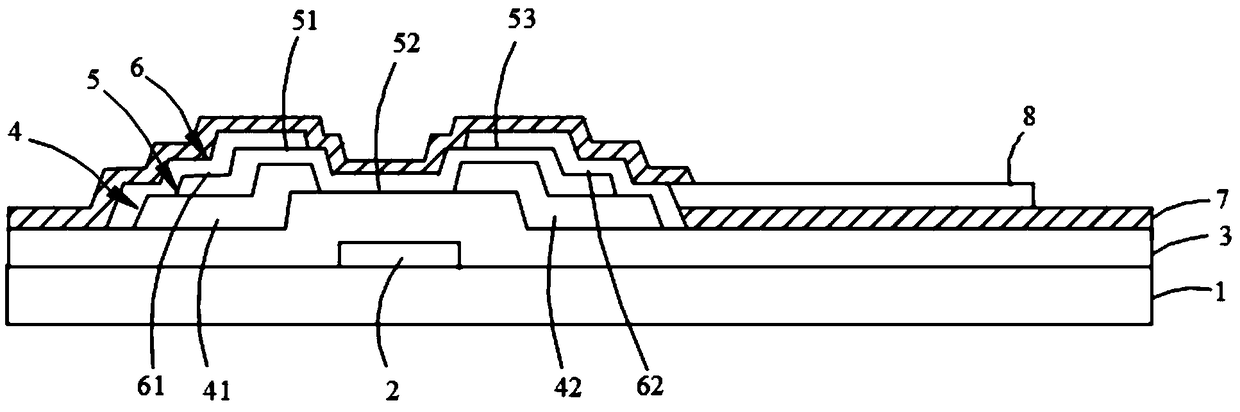

[0053] refer to figure 2 , the array substrate in this embodiment includes a plurality of thin film transistors 10, and the plurality of thin film transistors are arranged in an array. The thin film transistor 10 includes a substrate 1 , a gate 2 , a gate insulating layer 3 , a first metal layer 4 , an active layer 5 , a second metal layer 6 , and a passivation layer 7 . The gate 2 is arranged on the substrate 1, the gate insulating layer 3 covers the gate 2, the first metal layer 4 includes a first electrode 41 and a second electrode 42 arranged at intervals on the gate insulating layer 3, and the second metal layer 6 includes The source electrode 61 and the drain electrode 62 arranged at intervals, the source electrode 61 is located on the first electrode 41 and is in contact with the first electrode 41, the drain electrode 62 is located on the second electrode 42 and is in contact with the second electrode 42, and the active layer 5 includes The source contact end 51, the...

Embodiment 2

[0088] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the source 61 is not in contact with the first electrode 41 , and the drain 62 is not in contact with the second electrode 42 .

[0089] refer to Figures 9a-9j , the preparation method of the present embodiment adopts a half-tone mask process, and the preparation method comprises the steps of:

[0090] S1, provide a substrate 1, such as Figure 9a shown;

[0091] S2, form the gate 2 and the gate insulating layer 3 on the substrate 1, the gate insulating layer 3 covers the gate 2, such as Figure 9b shown;

[0092] S3, forming a first metal layer 4 on the gate insulating layer 3, the first metal layer 4 includes a first electrode 41 and a second electrode 42 arranged on the gate insulating layer 3 at intervals, such as Figure 9c shown;

[0093] S4, sequentially depositing the active material layer 50, the second metal material layer 60, and the third photoresist layer 70 on the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com