A manufacturing process of a yin-yang board

A production process, a technology of yin and yang boards, which is applied in printed circuit manufacturing, electrical components, and simultaneous processing of multiple printed circuits. Reduce the effect of wire changing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

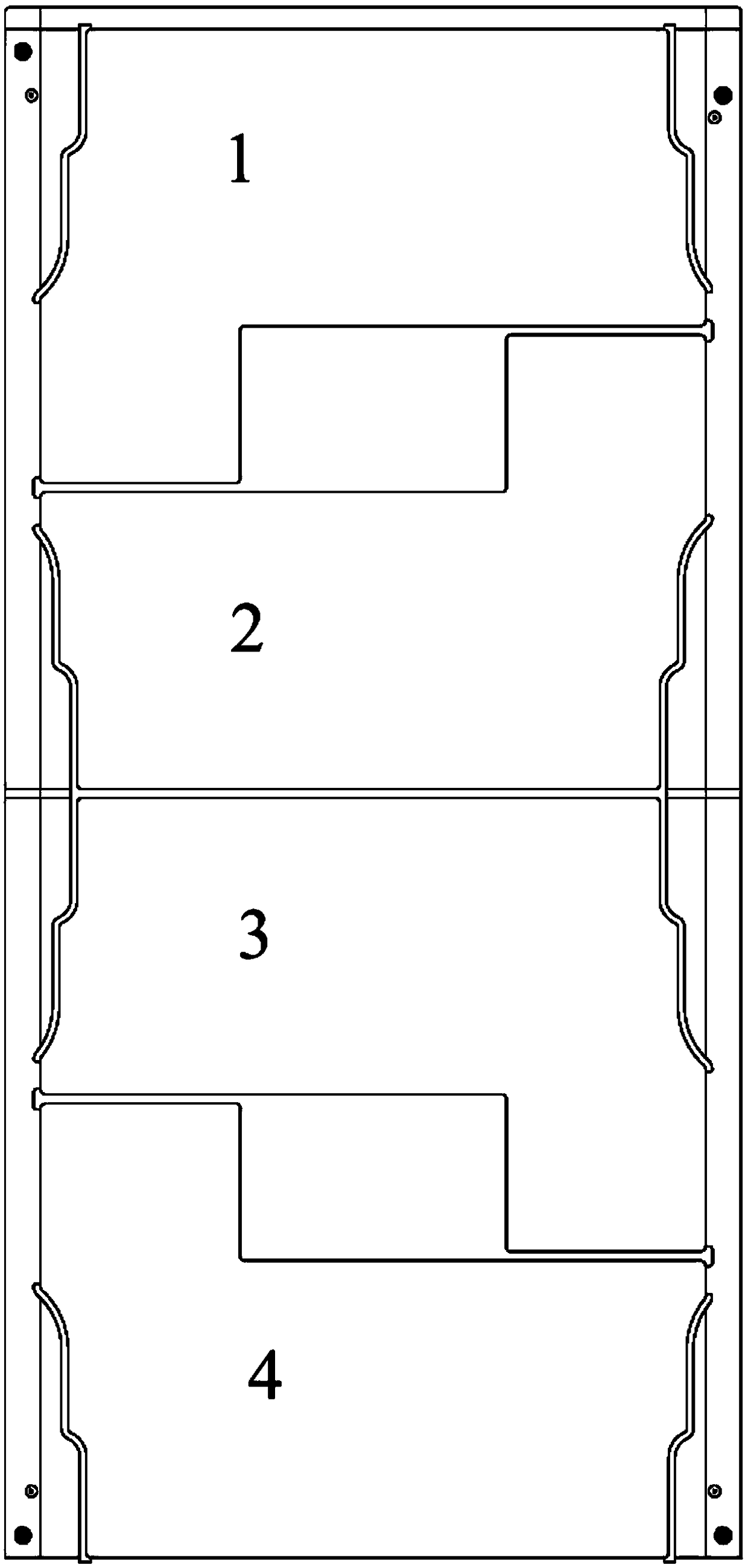

[0030] Refer to attached figure 1 , a manufacturing process of a yin-yang board using 4 pieces is as follows:

[0031] 1) Evaluate whether it can be designed as a yin-yang board:

[0032] a. First of all, there is a heavy component (inductor) on the PCB, which is easy to drop, so adjust the temperature difference between the upper and lower layers of the reflow soldering zone to ensure that the component does not fall. The layer temperature difference increases to above 20°C;

[0033] b. The length of the PCB board is 90cm, and the working range of the placement machine is 460cm*520cm. Since there are protruding parts on the edge of the PCB board, long splicing is used, and the utilization rate of raw materials and the length are too large. It is easy to cause deformation if it is long, so it is combined to use 4 pieces, as attached figure 1 ;

[0034] c. There are about 260 kinds of materials (2600 components) on the 4-panel board, so 3 placement machines are used to moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com