Full compliant dry electrode based on printing technology and preparation method thereof

A printing technology and dry electrode technology, which is applied in the field of biomedicine and materials, can solve the problems of undisclosed flexible electrode materials, formulas and preparation methods, and it is difficult to achieve high precision and high efficiency, so as to improve production efficiency and adaptability The effect of strong signal acquisition stability and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Preparation of flexible and stretchable substrate: Mix polydimethylsiloxane (PDMS) prepolymer and its curing agent at a mass ratio of 10:1, spin-coat to form a film, and cure at room temperature to 80°C for 10 minutes ~24h is a semi-cured flexible stretchable substrate, and the thickness of the substrate film is controlled at about 0.1mm by the speed and time of spin coating;

[0045] 2) Preparation of flexible conductive paste: use PDMS prepolymer and its curing agent as the polymer, silver powder (Ag) as the conductive element, and prepare PDMS / Ag conductive paste by stirring and blending, wherein the solid content of the Ag powder is 75 ~85wt%;

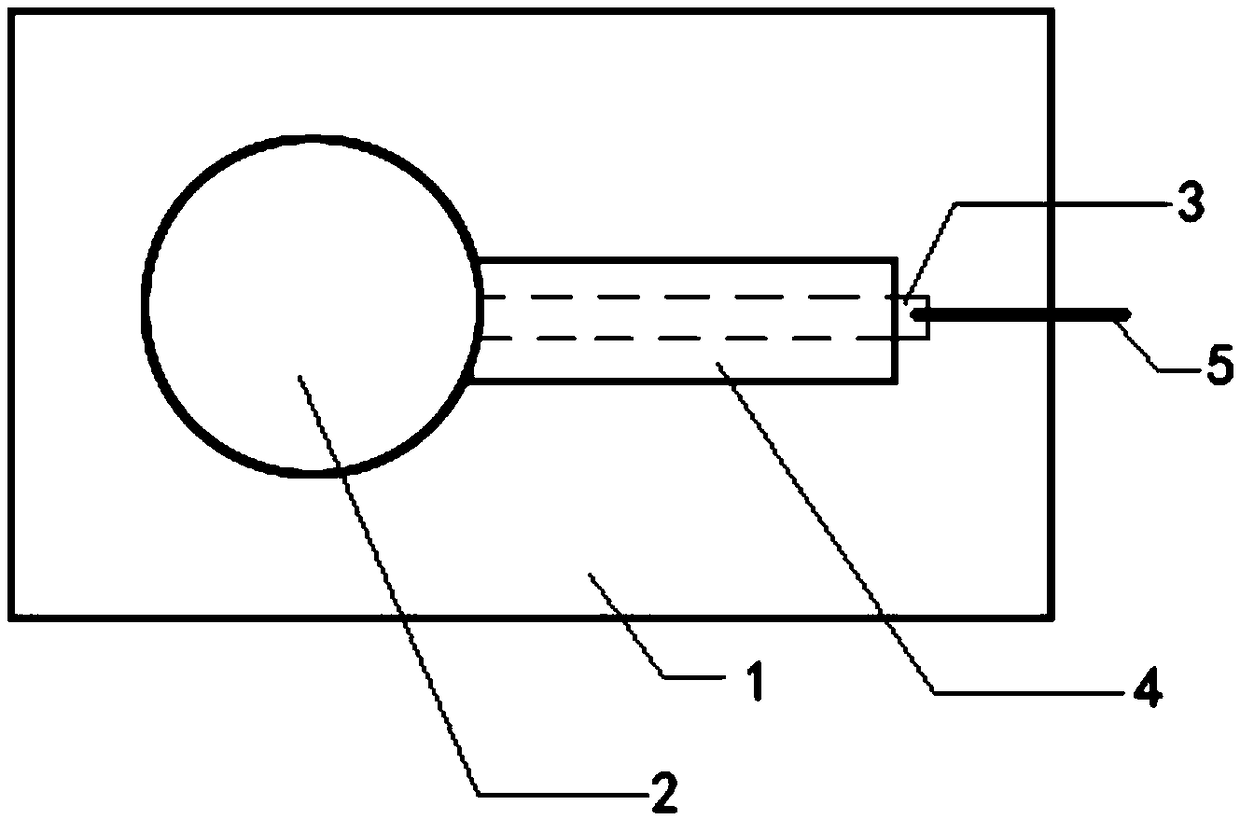

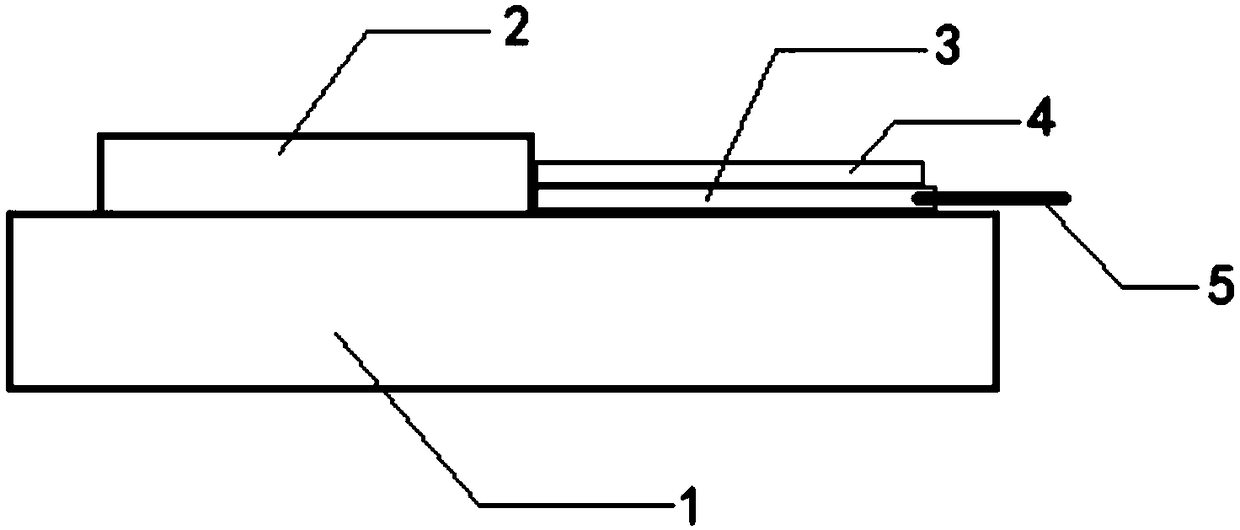

[0046] 3) Preparation of single-channel flexible and stretchable electrode units and electrode leads: Print PDMS / Ag conductive paste on the surface of PDMS substrate by screen printing process, and then cure at room temperature to 120°C for 30min to 24h to form PDMS / Ag Ag electrode unit and electrode leads. Since the po...

Embodiment 2

[0051] 1) Preparation of flexible and stretchable substrate: using styrene-butadiene-styrene (SBS) block copolymer as raw material and toluene as solvent, prepare a certain concentration of SBS / toluene solution, pass through in a flat container Pouring and drying at room temperature to 100°C for 2h to 24h to form a film. The thickness of the SBS film is controlled to be about 0.2 mm by the size of the container and the pouring amount of the SBS / toluene solution.

[0052] 2) Preparation of flexible conductive paste: use SBS / toluene solution as polymer and carbon black (CB) as conductive element, and prepare SBS / CB conductive paste by stirring and blending, wherein the solid content of CB is 12-18wt%;

[0053] 3) Preparation of single-channel flexible and stretchable electrode units and electrode leads: Print SBS / CB conductive paste on the surface of SBS film substrate by metal mask printing process, and then cure at room temperature to 100°C for 30min to 24h. After the toluene...

Embodiment 3

[0057] 1) Preparation of flexible and stretchable substrate: use thermoplastic polyurethane elastomer (TPU) as raw material and tetrahydrofuran (THF) as solvent to prepare a certain concentration of TPU / THF solution, and pour it in a flat container at room temperature ~ 60 Dry at ℃ for 30min~12h to form a film. The thickness of the TPU film is controlled to be about 0.3 mm by the size of the container and the pouring amount of the TPU / THF solution.

[0058] 2) Preparation of flexible conductive paste: TPU / THF solution is used as polymer and carbon nanotube (CNT) is used as conductive element, and TPU / CNT conductive paste is prepared by ultrasonic blending, wherein the solid content of CNT is 8-12wt% ;

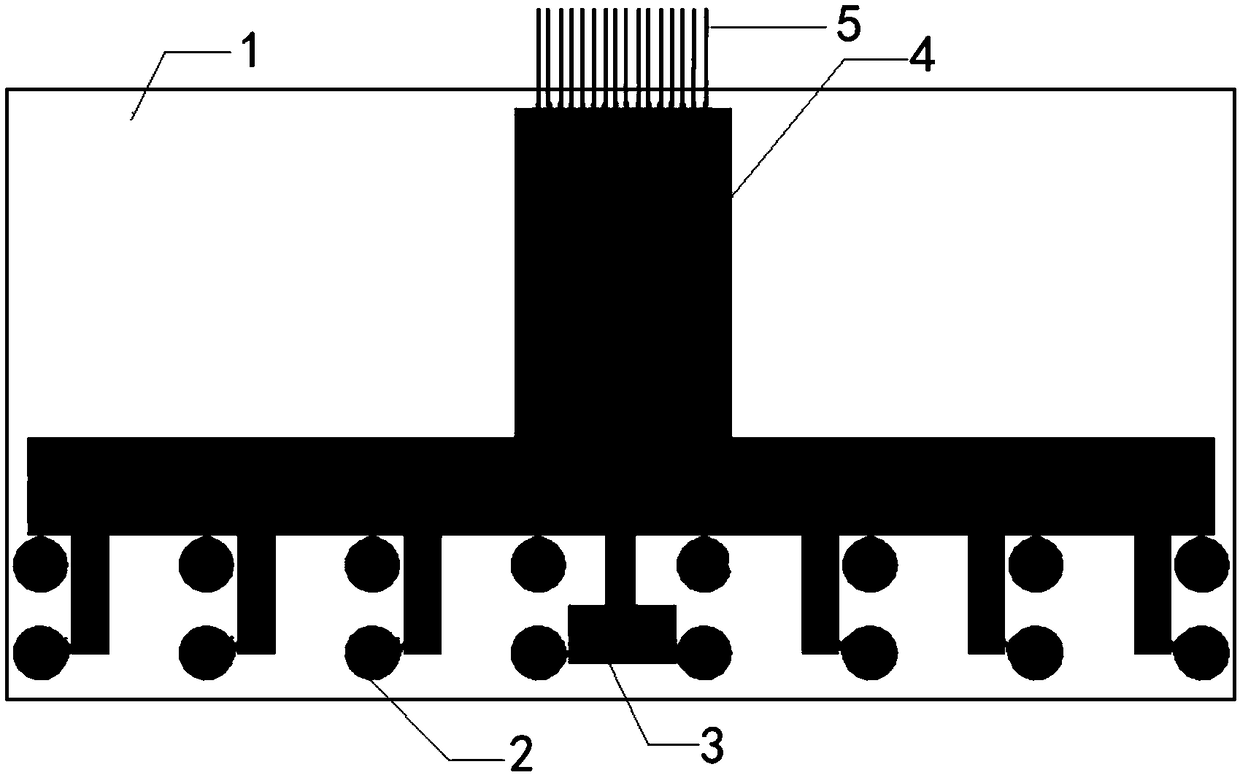

[0059] 3) Preparation of multi-channel flexible and stretchable electrode units and electrode leads: 3D printing technology was used to print TPU / CNT conductive paste on the surface of TPU film substrate, and then cured at room temperature to 60°C for 30min to 12h to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com