Process for preparing high-purity quartz sand by using composite method

A technology of high-purity quartz sand and composite method, used in wet separation, chemical instruments and methods, solid separation, etc., can solve the problems of insufficient purity of quartz sand, difficult to meet the needs of enterprises, low separation efficiency, etc., and improve the grade. , The effect of low pharmaceutical consumption and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

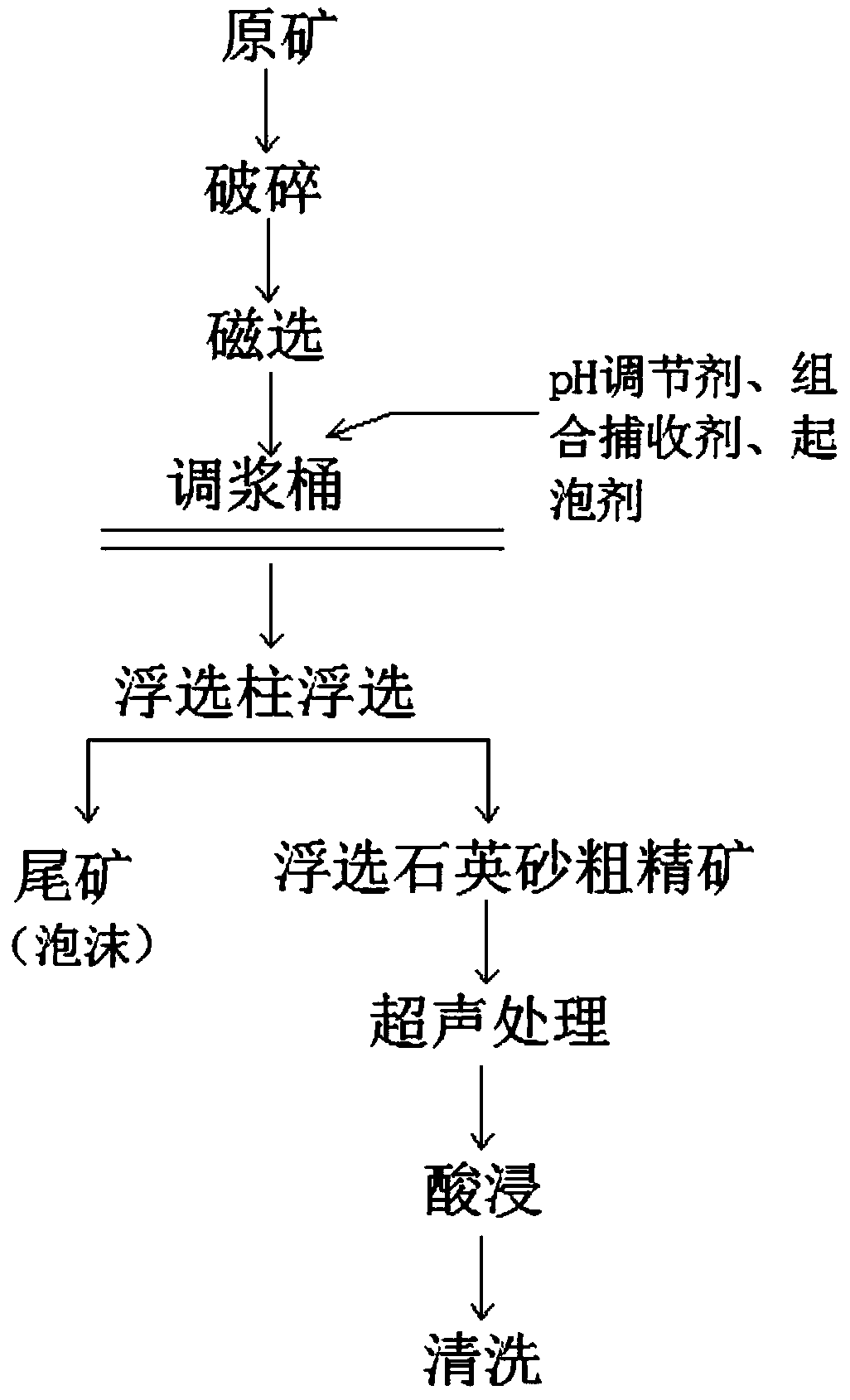

[0041] A process for preparing high-purity quartz sand by a composite method, comprising:

[0042] 1) Crushing: Crushing the quartz sand ore to prepare 40-180 mesh quartz sand.

[0043] 2) Magnetic separation: use a magnetic separator to rough the quartz sand, remove some magnetic impurities, and obtain a magnetically separated quartz sand coarse concentrate;

[0044] 3) Slurry: Add the magnetically separated quartz sand coarse concentrate into the slurry tank, first add a pH regulator to adjust the pH of the slurry to 6-7, and then add a collector (diethylamine sodium methoxide xanthate: xanthic acid Acrylic ester=1:1) 150g / t, after stirring for 8 minutes, add 2# oil 60g / t, after stirring for 5 minutes, pump into the flotation column for flotation; the pH regulator is one of oxalic acid, hydrochloric acid, sulfuric acid one or more kinds;

[0045] 4) Flotation: pump the quartz sand coarse concentrate slurry into the cyclone static micro-bubble flotation column for flotation...

Embodiment 2

[0050] A process for preparing high-purity quartz sand by a composite method, comprising:

[0051] 1) Crushing: Crushing the quartz sand ore to prepare 40-180 mesh quartz sand.

[0052] 2) Magnetic separation: use a magnetic separator to rough the quartz sand, remove some magnetic impurities, and obtain a magnetically separated quartz sand coarse concentrate;

[0053]3) Slurry: Add the coarse concentrate of magnetically separated quartz sand into the slurry tank, first add a pH regulator to adjust the pH of the slurry to 6, and then add a collector (diethylamine sodium methoxide xanthate: propylene xanthate =1:1) 200g / t, after stirring for 10 minutes, add 2# oil 90g / t, and after stirring for 6 minutes, pump into the flotation column for flotation; the pH regulator is one of oxalic acid, hydrochloric acid, sulfuric acid or various;

[0054] 4) Flotation: pump the quartz sand coarse concentrate slurry into the cyclone static micro-bubble flotation column for flotation, the flo...

Embodiment 3

[0059] A process for preparing high-purity quartz sand by a composite method, comprising:

[0060] 1) Crushing: Crushing the quartz sand ore to prepare 40-180 mesh quartz sand.

[0061] 2) Magnetic separation: use a magnetic separator to rough the quartz sand, remove some magnetic impurities, and obtain a magnetically separated quartz sand coarse concentrate;

[0062] 3) Slurry: Add the coarse concentrate of magnetically separated quartz sand into the slurry tank, first add a pH regulator to adjust the pH of the slurry to 6, and then add a collector (diethylamine sodium methoxide xanthate: propylene xanthate =1:1) 180g / t, after stirring for 10 minutes, add 2# oil 80g / t, and after stirring for 6 minutes, pump into the flotation column for flotation; the pH regulator is one of oxalic acid, hydrochloric acid, sulfuric acid or various;

[0063] 4) Flotation: pump the quartz sand coarse concentrate slurry into the cyclone static micro-bubble flotation column for flotation, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com