Concrete preparation processing equipment and processing technology thereof

A technology for processing equipment and concrete, applied in the field of concrete preparation and processing equipment and its processing technology, can solve the problems of low degree of automation, poor screening effect, low screening efficiency, etc., so as to improve efficiency and effect, improve screening efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

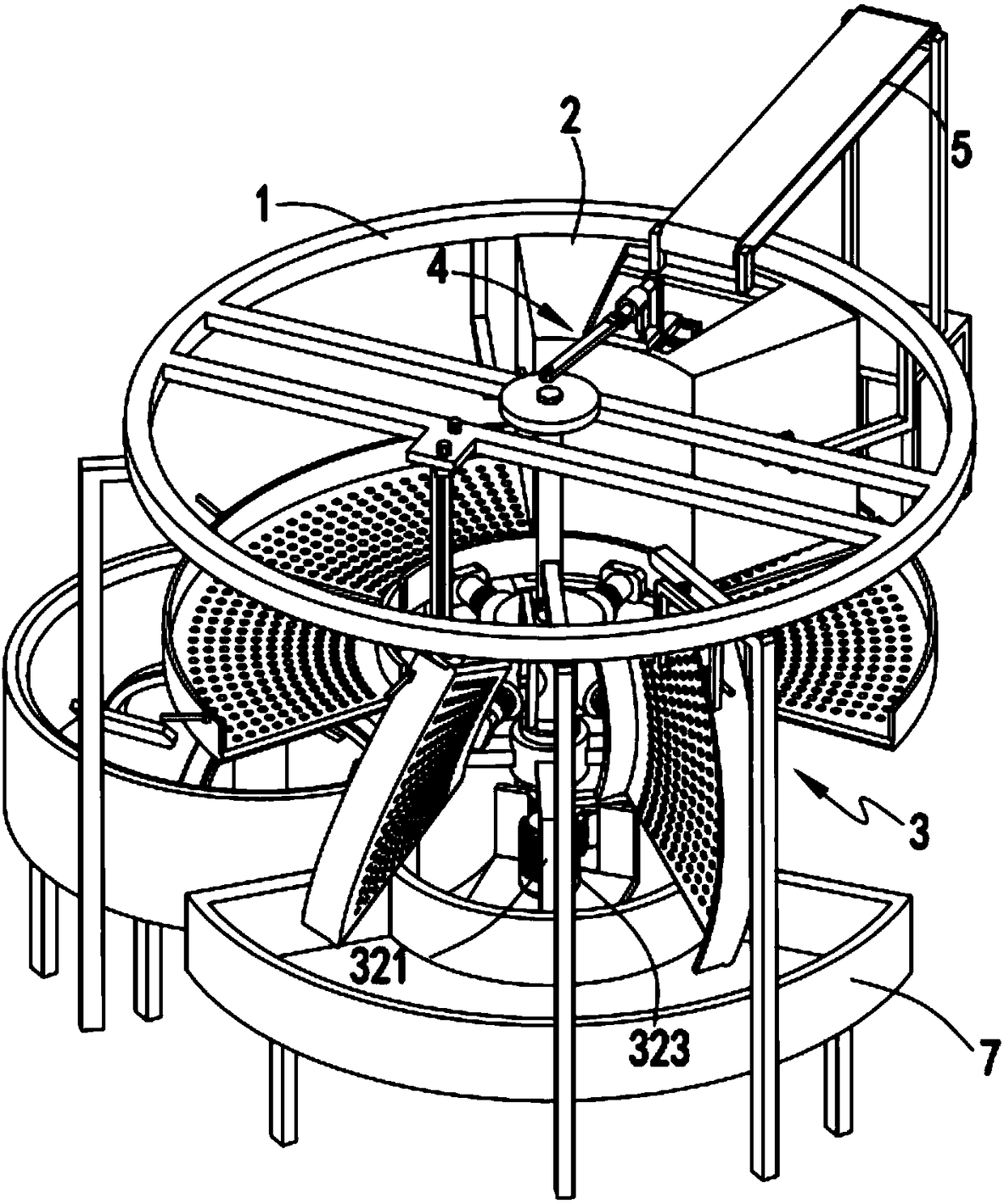

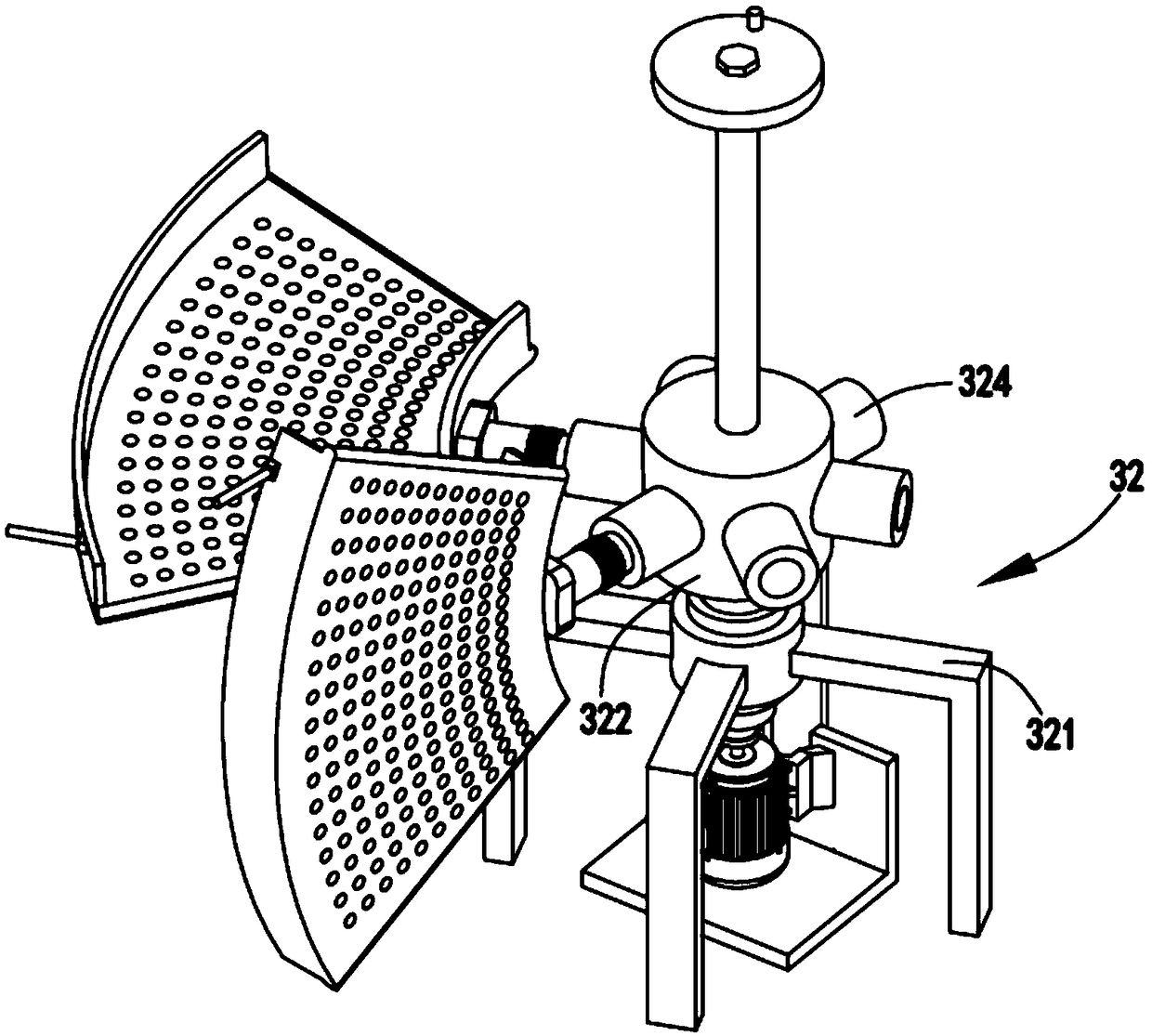

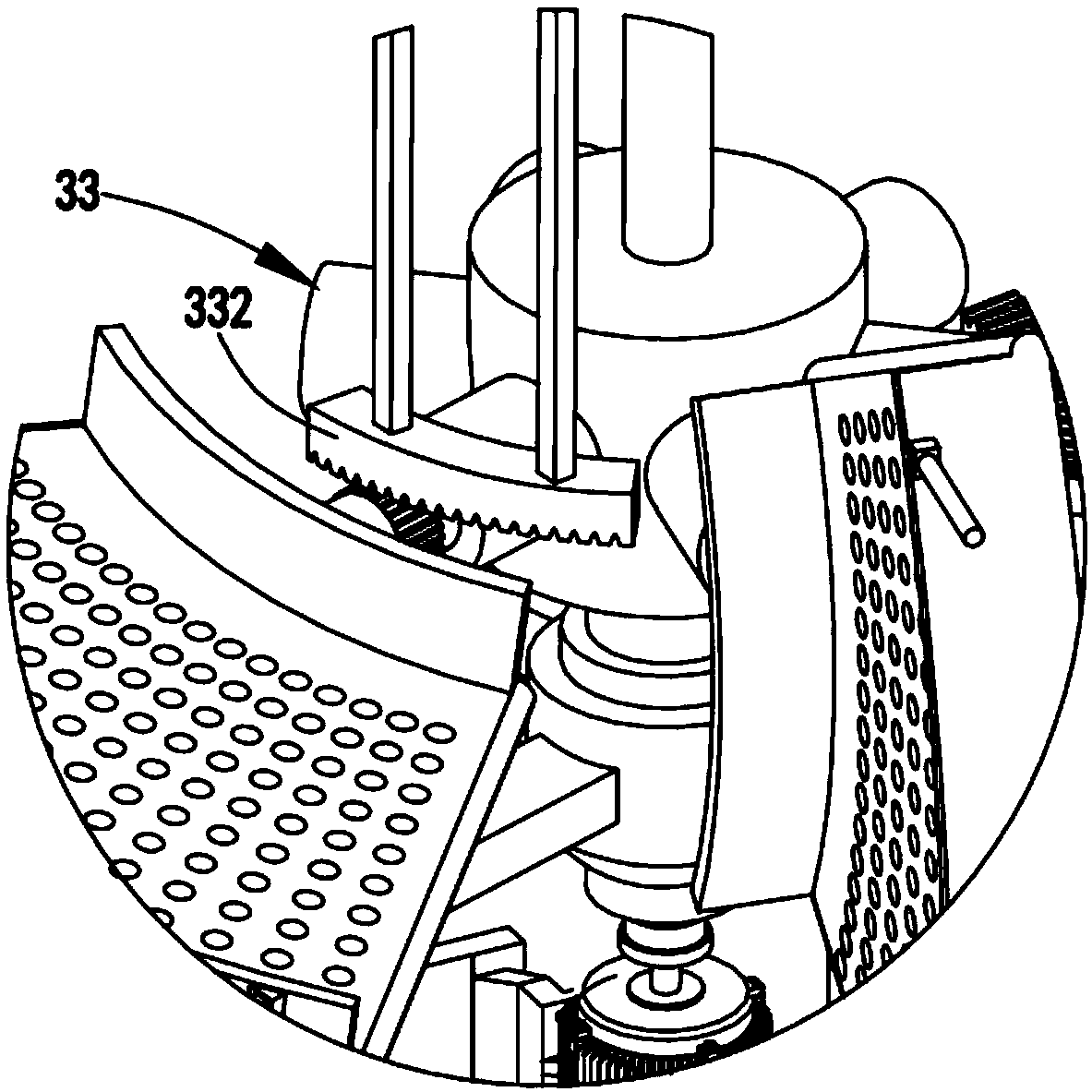

[0049] like Figure 1 to Figure 10 As shown, a concrete preparation and processing equipment includes a frame 1, a sieving barrel 2 is arranged on the frame 1, and a rotary screening device 3 is arranged below the sieving barrel 2, and the rotary screening device 3 includes several screening assemblies 31 arranged in an array along the circumferential direction, a rotating mechanism 32 for driving the screening assemblies 31 to make a circular motion through the bottom of the screening bucket 2, and a turning mechanism 33 for driving the screening assemblies 31 to turn over, When the screening assembly 31 passes through the bottom of the screening bucket 2, the material in the screening bucket 2 is screened, and the turning mechanism 33 drives the screening assembly 31 that completes a screening to turn over to make the screening assembly 31 go up and screen The remaining large particles fall; the frame 1 is also provided with a shaking mechanism 34, and the shaking mechanism ...

Embodiment 2

[0064] like figure 1 and Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, the sieve bucket 2 is also provided with a material picking mechanism 4 for stirring the material in the sieving material bucket 2, and the material picking mechanism 4 includes Set coaxially with the main shaft 322 and rotate the turntable 41 driven by the main shaft 322, the sliding seat 42 fixed on the sieve material barrel 2, the sliding bar 43 slidably arranged on the sliding seat 42, the sliding bar 43 fixed at one end and the end The material part 44 that the part stretches into the sieve bucket 2 and one end is rotatably connected with the other end of the slide bar 43 , and the ...

Embodiment 3

[0067] like Figure 11 Shown, a kind of concrete preparation process comprises the following steps:

[0068] (1) Feeding process, the feed belt 5 transports the material to be screened to the sieve bucket 2;

[0069] (2) screening process, the screening assembly 31 is rotated to the bottom of the screening bucket 2, and the material to be screened in the screening bucket 2 is moved by the scraping mechanism 4, and the screening plate 312 is used to screen the material, The fine granular material falls downwards, and the coarse granular material stays on the screening plate 312;

[0070] (3) material turning process, the sieve plate 312 that finishes screening work in the step (2) rotates around the main shaft 322 to the material turning station place, at the material turning station place, the mode that drives the gear rotation by rack makes this screening The plate 312 rotates around the rotating shaft 311 to make the coarse particles left on the sieve plate 312 fall;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com