Continuous production method of phosphorus pentafluoride

A technology of phosphorus pentafluoride and production method, applied in phosphorus halide/oxyhalide and other directions, can solve the problems of uncontrolled reaction, fluctuation of reaction rate, high safety risk, etc., to avoid explosion accidents, stable reaction process, and easy reaction control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

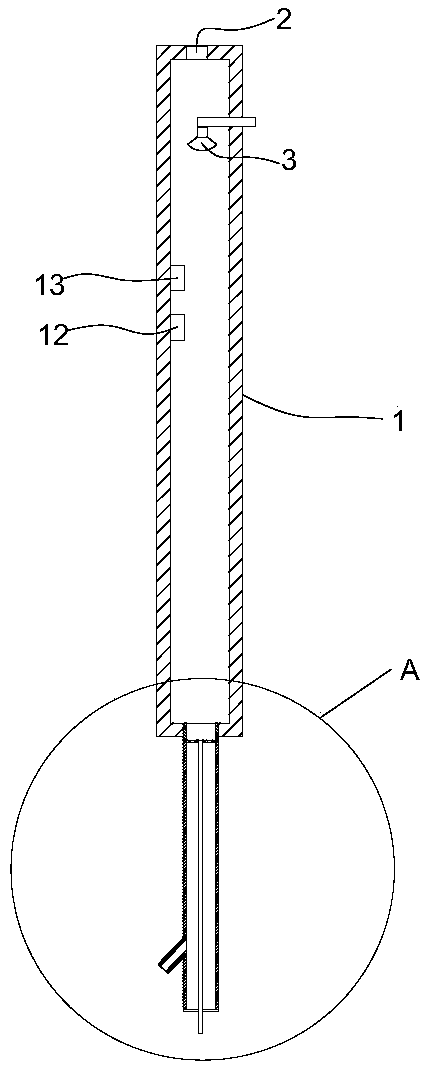

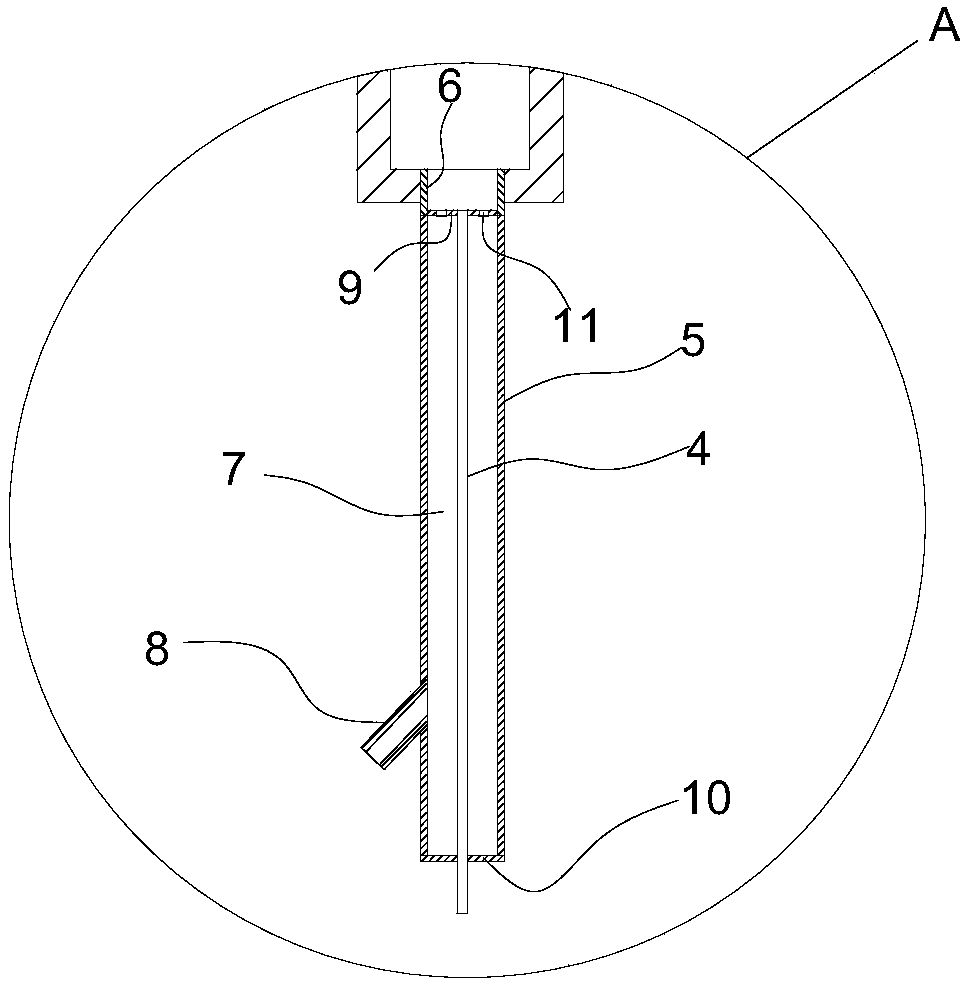

[0027] like figure 1 and figure 2 As shown, the vertical continuous production equipment for phosphorus pentafluoride is used for continuous production of phosphorus pentafluoride. The gas port 2, the side wall of the vertical reaction vessel 1 below the gas port 2 is provided with an atomizing nozzle 3, and the outlet of the atomizing nozzle 3 faces downward.

[0028] Use heating equipment to heat the solid yellow phosphorus into a liquid state for later use, and use an air pump to transport the inert gas from the inert gas inlet pipe 5 to the inlet nozzle 8, and the inert gas enters the vertical reaction vessel 1 after passing through the inert gas flow channel 7 and the vent hole 11, All the air in the vertical reaction vessel 1 is squeezed out. Then use the delivery pump to transport the liquid yellow phosphorus to the atomizing nozzle 3. The liquid yellow phosphorus is atomized by the atomizing nozzle 3 to form a phosphorus spray and then flow downward. The spray speed...

Embodiment 2

[0030] The equipment described in Example 1 was used to continuously produce phosphorus pentafluoride, and some parameters were changed, wherein, the spraying speed of phosphorus spray was 1 m / s; the temperature was 250°C. Adjust the distance between the nozzle of phosphorus spray and the nozzle of fluorine-containing gas to 15m, and the ejection speed of the mixed gas of fluorine gas and inert gas to 5m / s; through monitoring, it can be seen that the reaction temperature of this process is 250-500°C Fluctuation, the reaction pressure fluctuates within 0.1-0.5MPa, the temperature and pressure fluctuations are small, and the reaction proceeds smoothly.

Embodiment 3

[0032] The equipment described in Example 1 was used to continuously produce phosphorus pentafluoride, and some parameters were changed, wherein, the spraying speed of phosphorus spray was 10 m / s; the temperature was 150°C. Adjust the distance between the nozzle of the phosphorus spray and the nozzle of the fluorine-containing gas to be 10m. During the reaction, no inert gas is passed into but only fluorine gas (that is, the fluorine-containing gas is fluorine gas), and the ejection speed of the fluorine gas is 15m / s; It can be seen from the monitoring that with this process, the reaction temperature fluctuates at 250-500° C., the reaction pressure fluctuates at 0.1-0.5 MPa, the temperature and pressure fluctuations are small, and the reaction proceeds smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com