Preparation method of ZrO2-based composite material resistant to high temperature

A composite material and high-temperature-resistant technology, which is applied in the field of ZrO2-based high-temperature-resistant composite materials prepared by the impregnation and cracking process of precursors, can solve the problems of low cracking efficiency, long cycle, easy cracking, etc., and achieve mature preparation technology, high production efficiency, and reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

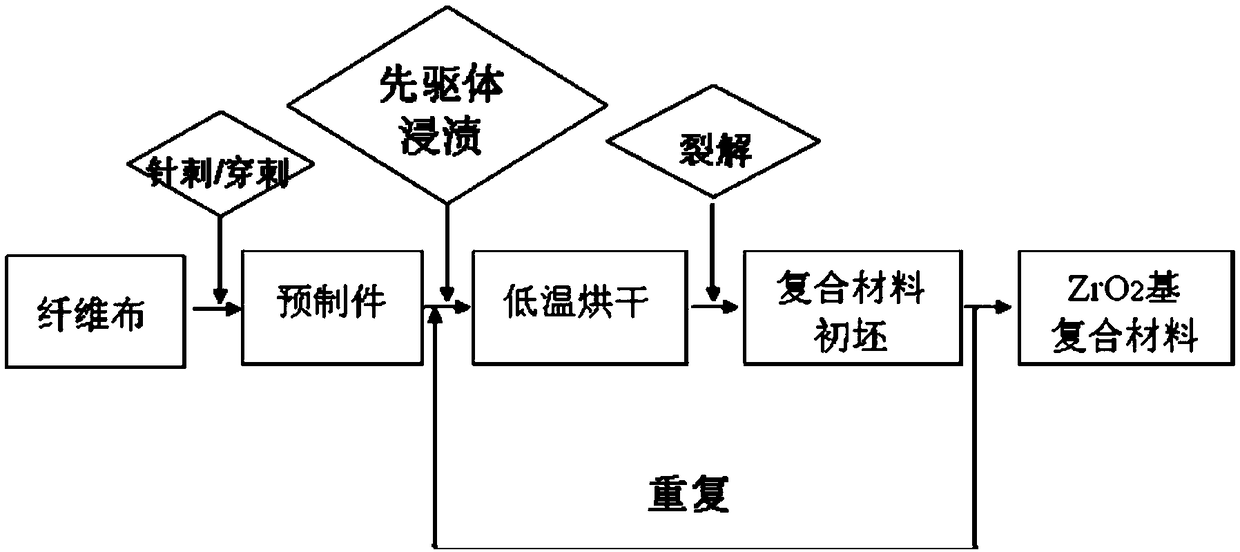

[0034] a ZrO 2 Matrix composite materials, the preparation method of which is as follows figure 1 shown, including the following steps:

[0035](1) Spread 30 layers of carbon fiber cloth with a thickness of 0.10mm, and then suture. The fiber used for suture is commercially available T800 carbon fiber. The T800 carbon fiber is more flexible and not easy to break. In order to obtain better mechanical properties, Design the distance between every two sutures to be 5mm;

[0036] (2) Clamp the fiber cloth obtained in step (1) with a graphite mold, place it in a vacuum container, and vacuum ZrO 2 Precursor, impregnated for 6h;

[0037] (3) Dry at room temperature for 2 hours, dry at 200°C and cool to room temperature naturally;

[0038] (4) Arranging the fibers treated in step (3) in a pyrolysis chamber for pyrolysis, the heat treatment temperature is 1000° C., and the treatment time is 1 h to cool to room temperature;

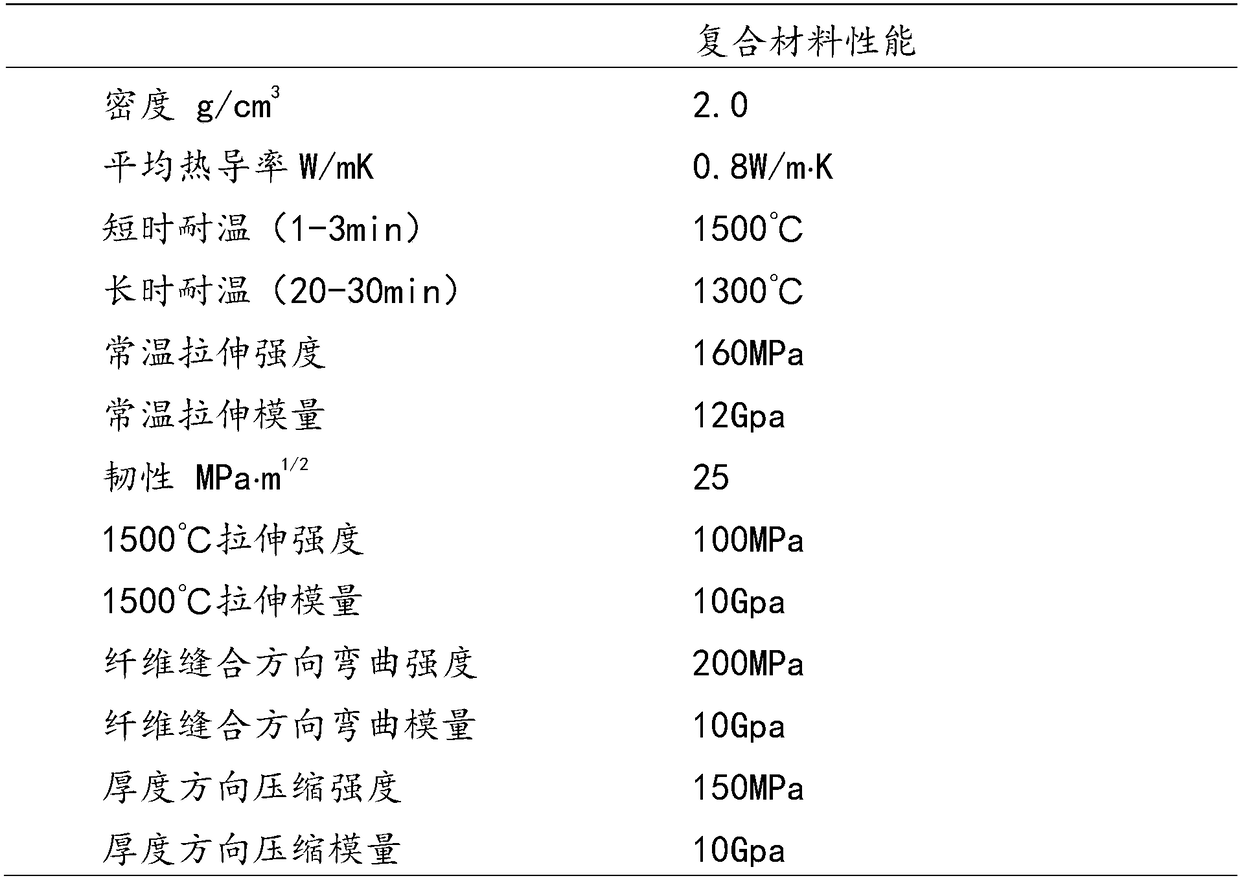

[0039] (5) After repeating step (2) to step (4) 15 times ...

Embodiment 2

[0043] a ZrO 2 Matrix composite materials, the preparation method of which is as follows figure 1 shown, including the following steps:

[0044] (1) Lay one layer of alumina fiber 2.5D woven piece, and then perform puncture treatment. The fiber used for acupuncture is 750Tex alumina fiber, and the distance between each two needle-punched lines is 8mm;

[0045] (2) Clamp the punctured alumina fiber 2.5D woven piece obtained in step (1) with a graphite mold, place it in a vacuum container, and vacuum ZrO 2 Precursor, after soaking for 4 hours, take it out and dry it;

[0046] (3) Low-temperature drying at a temperature of 150° C. for 4 hours;

[0047] (4) Place the alumina fiber 2.5D woven piece treated in step (3) in a pyrolysis chamber for pyrolysis, the pyrolysis temperature is 1200°C, the treatment time is 40min, and then cooled to room temperature;

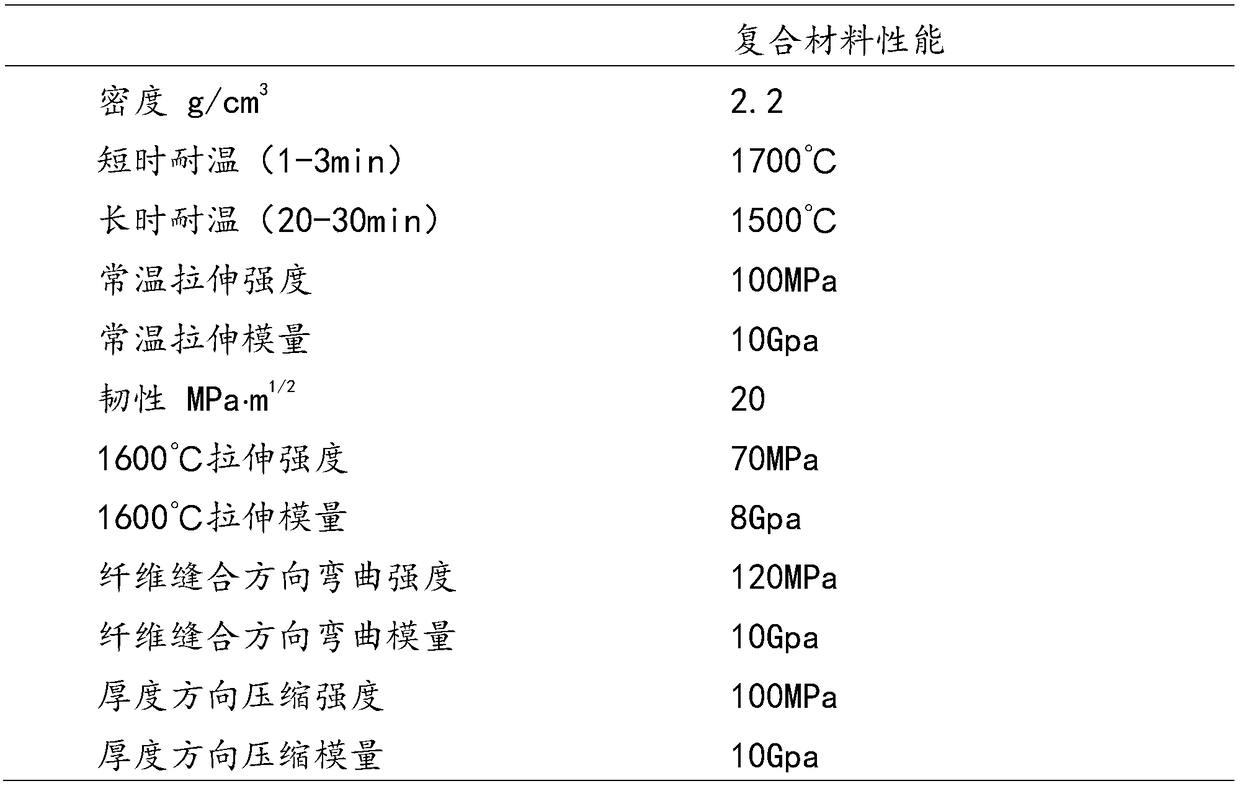

[0048] (5) Repeat steps (2)-(4) in sequence for 10 times, and then perform mechanical processing to achieve the required ...

Embodiment 3

[0054] a ZrO 2 Matrix composite materials, the preparation method of which is as follows figure 1 shown, including the following steps:

[0055] (1) Lay 3 layers of silicon carbide fiber cloth with a thickness of 0.9 mm, and then perform puncture treatment to form a "skin" of silicon carbide fiber cloth. The fiber used for acupuncture is 600Tex silicon carbide ceramic fiber. Every two needles Line spacing is 5mm;

[0056] (2) Clamp the silicon carbide fiber cloth "skin" obtained in step (1) with a graphite mold, place it in a vacuum container, and vacuum ZrO 2 Precursor, and then dried at a temperature of 100°C;

[0057] (3) Place the silicon carbide fiber cloth "skin" treated in step (2) in a high temperature furnace for cracking, the temperature is 1200°C, and the treatment time is 30 minutes to cool to room temperature;

[0058] (4) After repeating steps (2)-(3) in sequence for 12 times, mechanical processing is carried out to achieve the required size.

[0059] The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com